Novel CA (cement asphalt) mortar grouting bag

A technology of pouring bags and mortar, which is applied in the laying of tracks, roads, tracks, etc., can solve the problems of uncertain pouring shape, insufficient pouring, inconvenience, etc., and achieve the effects of ensuring stability, convenient construction, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Specific embodiments of the invention will be described in detail below in conjunction with the accompanying drawings.

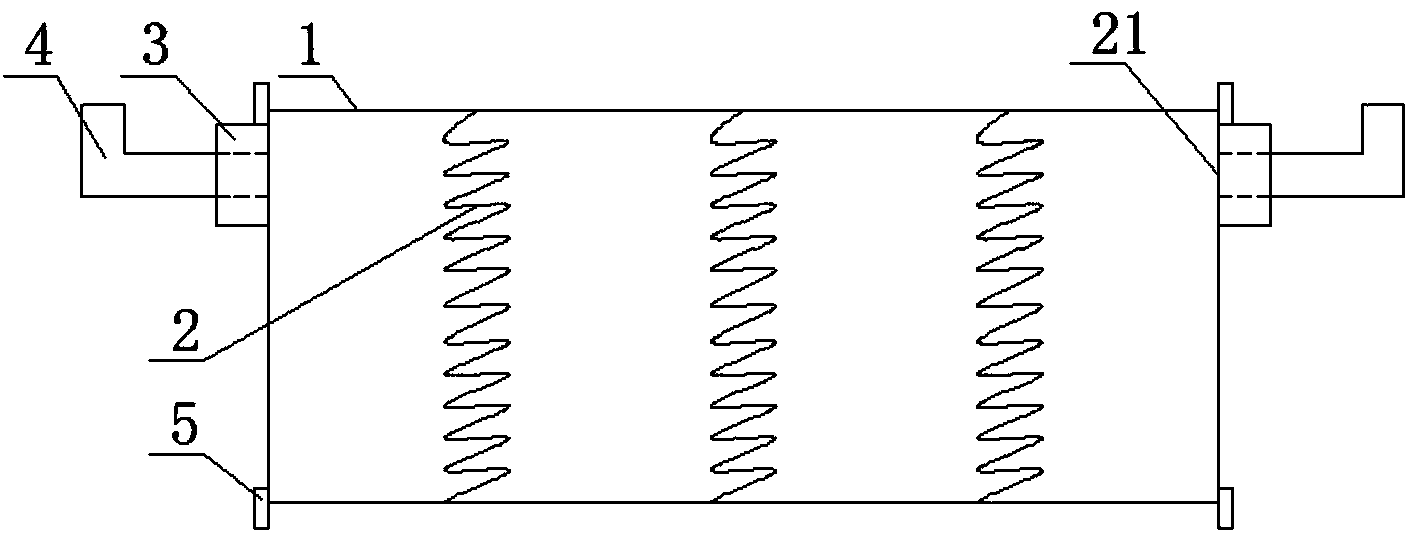

[0018] A new type of CA mortar filling bag, the filling bag 1 is a rectangular bag made of polypropylene non-woven fabric, including a feed port 11, an elastic element 2, a sealing member 3, an elbow filling pipe 4 and a baffle plate 5 The feeding port 11 is arranged on a pair of side surfaces of the perfusion bag 1, and the positions are symmetrical to each other; the sealing member 3 is a sleeve-like structure, and one end of the sealing member 3 is fixed at the position of the feeding port 11 of the perfusion bag 1, and The aperture is matched with the feeding port 11 of the filling bag 1, the other end of the sealing member 3 is connected with the elbow filling pipe 4, and the aperture is matched with the elbow filling pipe 4; several elastic elements 2 are evenly arranged inside the filling bag 1 , the two ends of the elastic element 2 are respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com