Centering anti-eccentric anti-waxing sucker-rod coupling

A sucker rod coupling and sucker rod technology, applied in drill pipes, cleaning appliances, drilling equipment, etc., can solve the problems of reducing the flow area, damage to sucker rods, occupation, etc., to reduce resistance, prevent The effect of waxing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail,

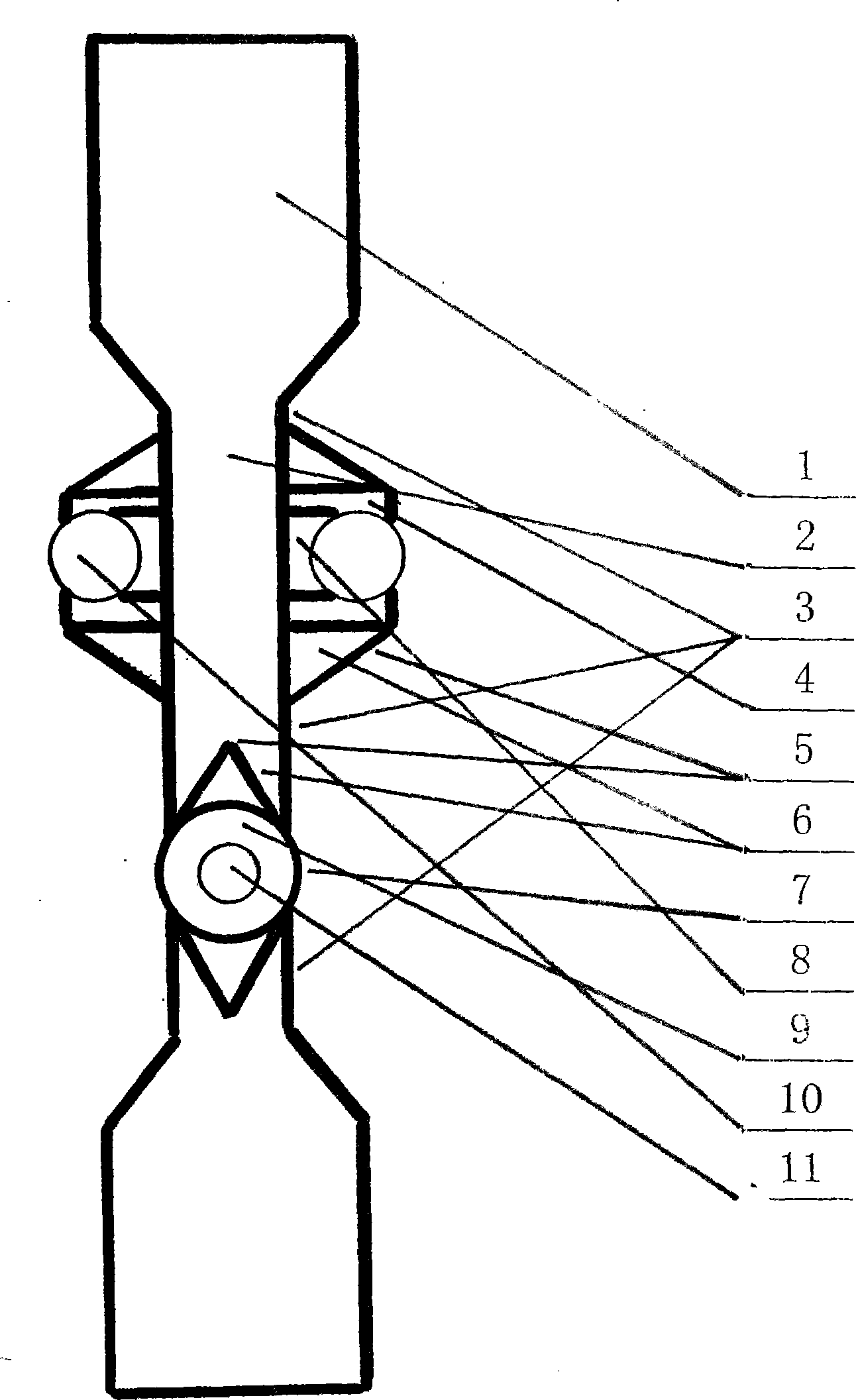

[0010] like figure 1 As shown: the coupling sucker rod body (2) is integrally and combinedly connected with a sucker rod standard body (4), and the sucker rod standard body (4) is combined with a magnet anti-wax body (8) and a rolling friction ball (10 ), the sucker rod standard body (4) has a water-facing line (5), a water-facing surface (6), a rolling friction hole (7), a sliding friction surface (9), and a rolling friction ball (10) is exposed from the rolling friction hole (7) The surface of the sucker rod is the rolling friction surface (11), and the space between the sucker rod standard bodies (4) is the well fluid flow channel (3).

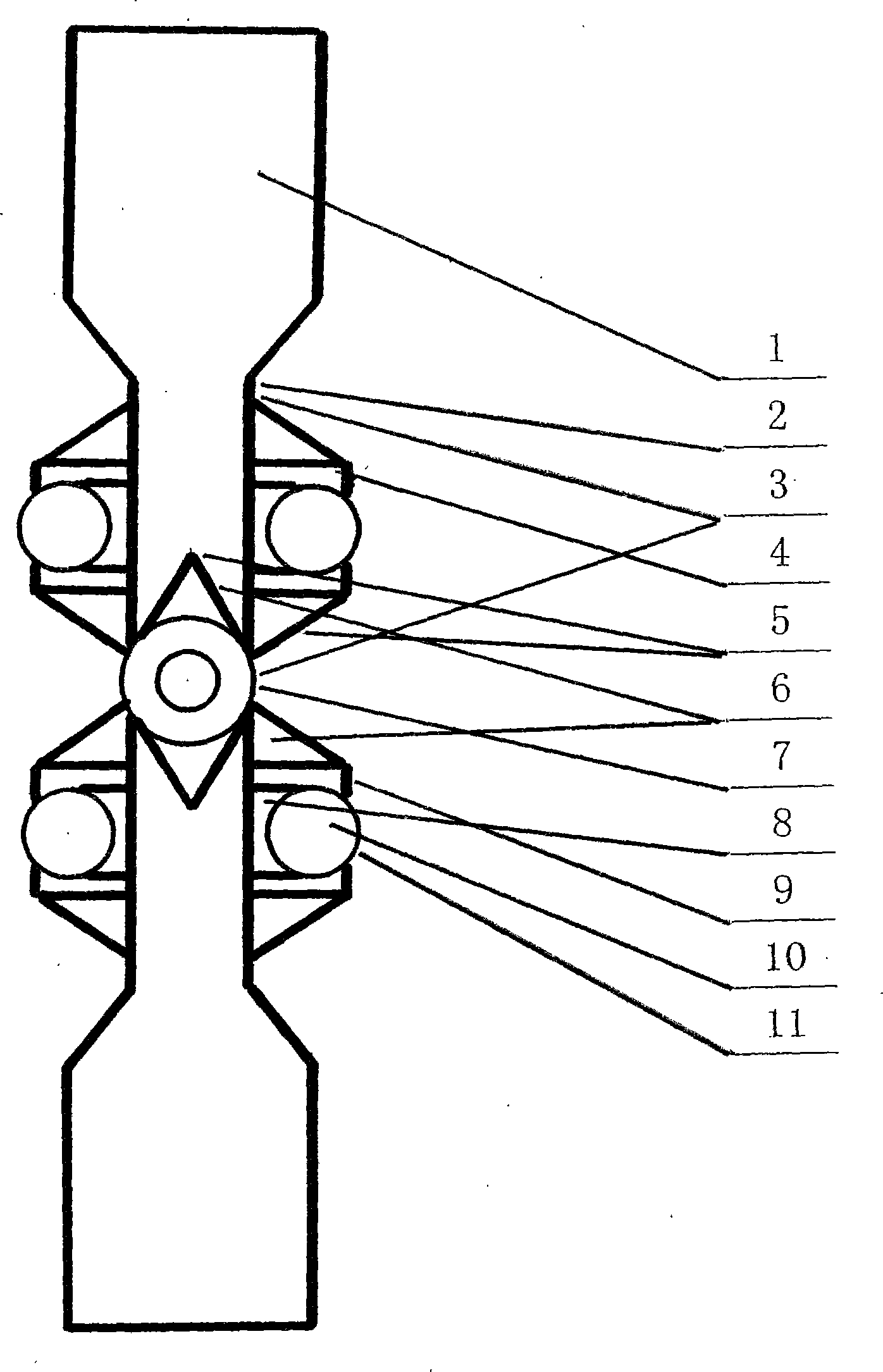

[0011] like figure 2 Shown: the sucker rod standard body (4) has the overall structure schematic diagram of 5 sucker rod standard bodies (4).

[0012] The optimum number of sucker rod standard bodies (4) on the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com