Low-frequency air spring vibration isolator with motion converter

A technology of air springs and converters, applied in gas shock absorbers, spring/shock absorbers, springs, etc., can solve problems such as system instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing, embodiment of the present invention is described in further detail:

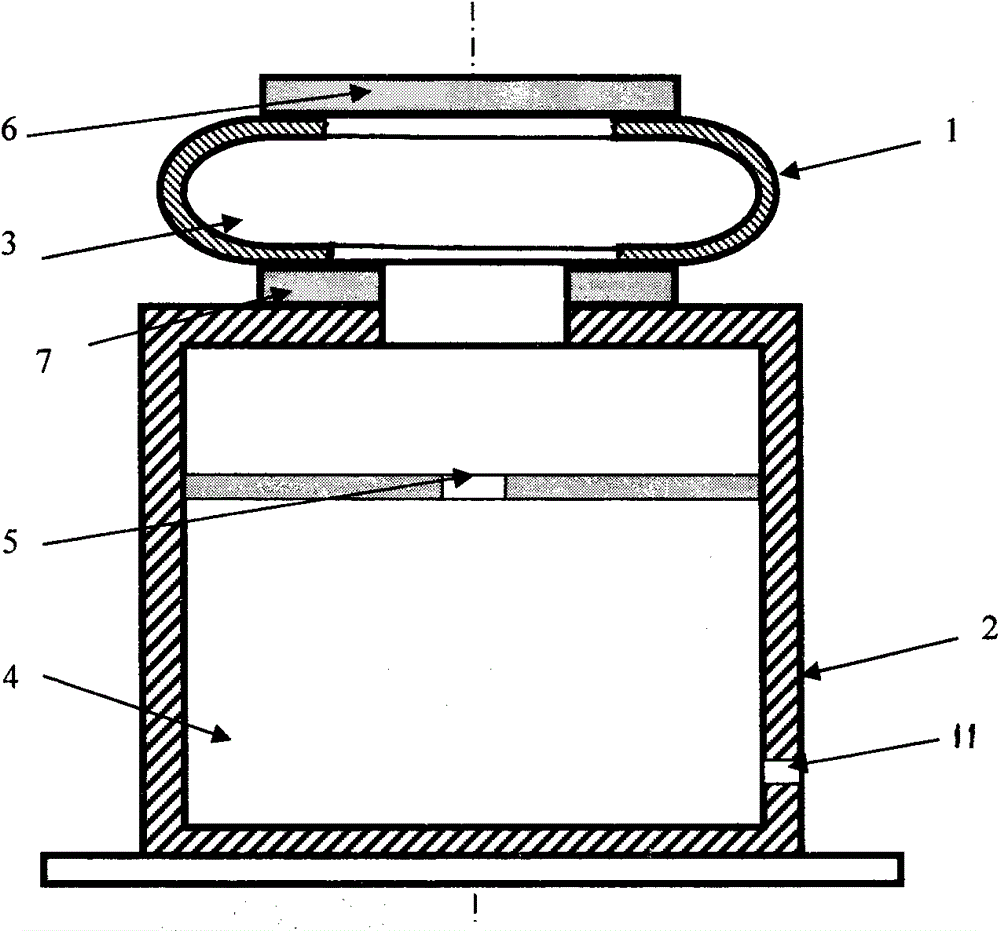

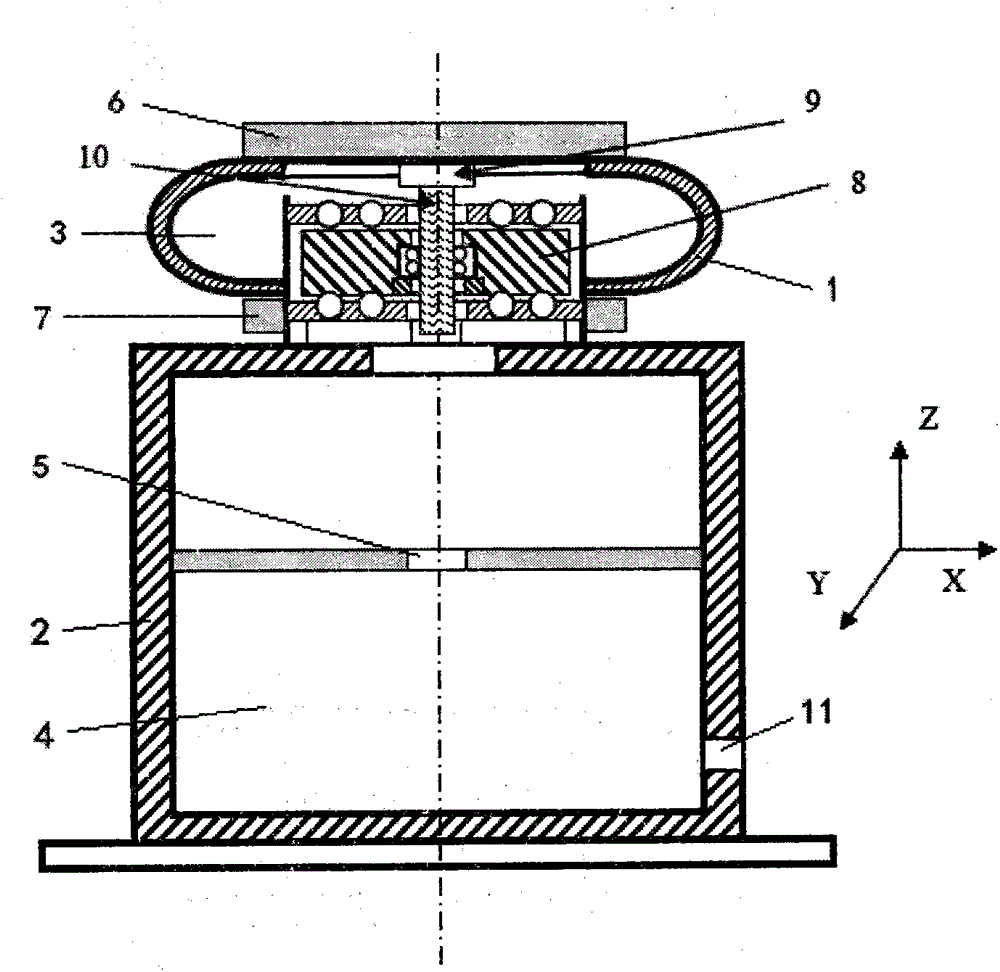

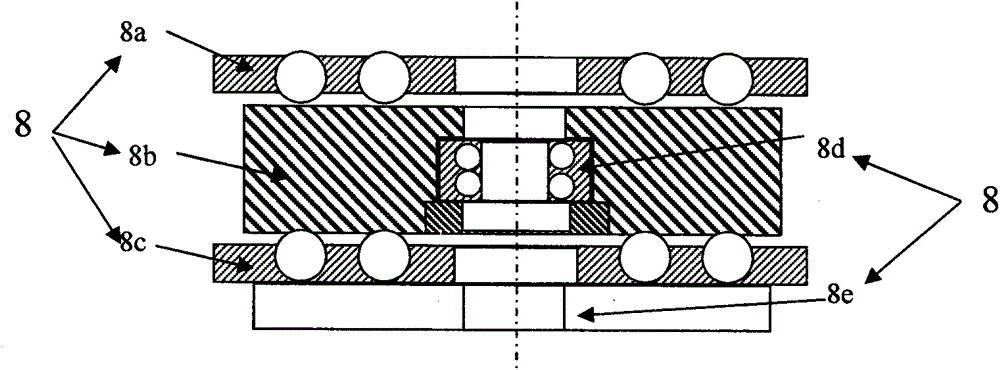

[0013] A low-frequency air spring vibration isolator with a motion converter, the vibration isolator is directly composed of an upper cover plate 6, a rubber bladder 1, a lower cover plate 7 and a cylinder 2 from top to bottom, wherein the rubber bladder 1 passes through The lower cover plate 7 is directly connected to the cylinder 2, and the main air chamber 3 and the auxiliary air chamber 4 are respectively formed in the rubber bag 1 and the cylinder 2. The compressed air enters the air cylinder 2 through the air inlet 11 arranged on the side wall of the cylinder 2. In the auxiliary air chamber 4, it enters the main air chamber 3 of the rubber bag 1 through the throttle hole 5 arranged in the auxiliary air chamber 4. On the upper end of the cylinder 2, a movement conversion is installed inside the rubber bag 1. device 8; the motion converter 8 is compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com