Double-segment seal gate valve

A gate valve and valve body technology, which is applied in the field of double-seal gate valves, can solve the problems of safety protection of discharge pressure, scratched gate and valve seat, and inability to discharge under pressure, and achieves improved wear resistance, reliable bilateral sealing and adhesion. low force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

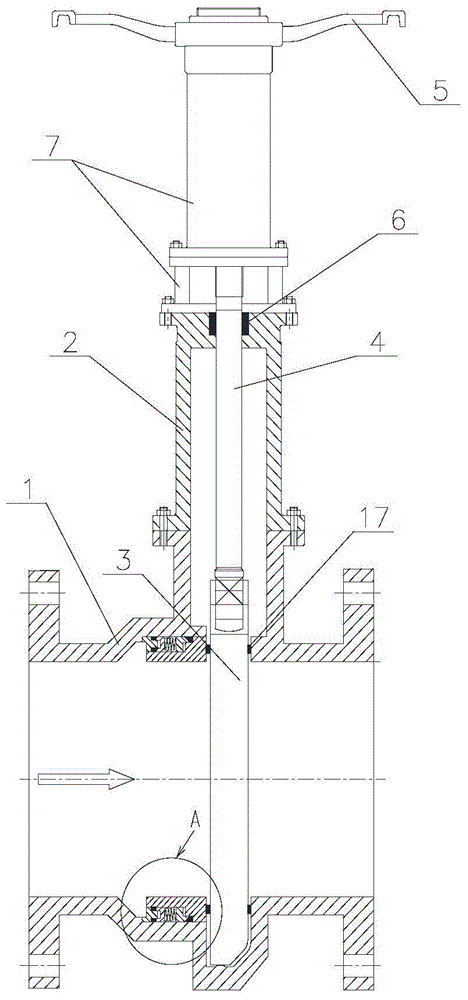

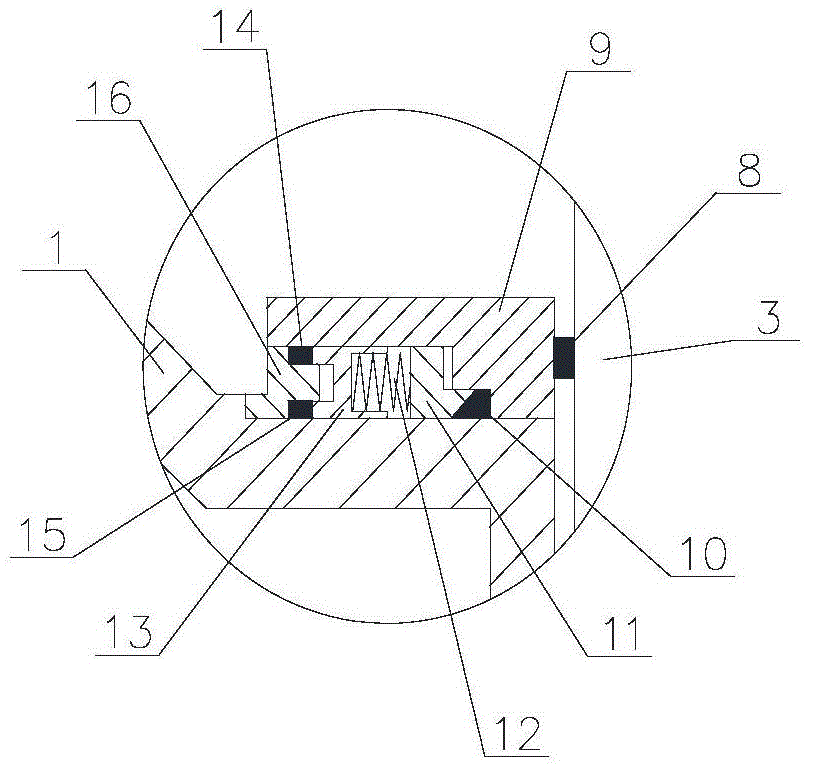

[0071] A double-stage sealed gate valve. The gate valve includes a valve body, a valve cover, a gate plate and a switch body. The valve body is cylindrical. The valve body includes an upstream valve body, a valve body cavity, a gate valve groove and a downstream valve body. The upstream valve body and A gate plate and a sealing device perpendicular to the axial direction of the valve body are arranged between the downstream valve bodies; the sealing device includes a cylindrical valve seat support with the same inner diameter and the outer diameter increases from upstream to downstream in the groove of the inner wall of the middle cavity of the valve body. Ring and the front cover, packing ring, spring support seat, spring and back cover which are successively arranged in the gap between the valve seat support ring and the cavity groove of the valve body along the direction from upstream to downstream; The axial direction of the valve body is vertical.

[0072] The valve cover...

Embodiment 2

[0107] A double-stage sealed gate valve. The gate valve includes a valve body, a valve cover, a gate plate and a switch body. The valve body is cylindrical. The valve body includes an upstream valve body, a valve body cavity, a gate valve groove and a downstream valve body. The upstream valve body and A gate plate and a sealing device perpendicular to the axial direction of the valve body are arranged between the downstream valve bodies; the sealing device includes a cylindrical valve seat support with the same inner diameter and the outer diameter increases from upstream to downstream in the groove of the inner wall of the middle cavity of the valve body. Ring and the front cover, packing ring, spring support seat, spring and back cover which are successively arranged in the gap between the valve seat support ring and the cavity groove of the valve body along the direction from upstream to downstream; The axial direction of the valve body is vertical.

[0108] The valve cover...

Embodiment 3

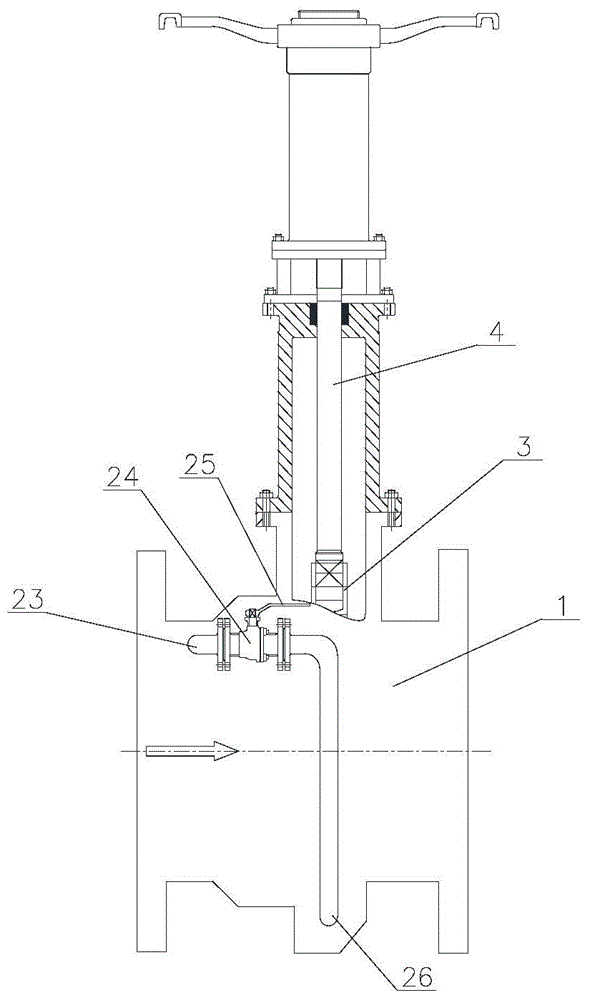

[0143] A double-stage sealed gate valve. The gate valve includes a valve body, a valve cover, a gate plate and a switch body. The valve body is cylindrical. The valve body includes an upstream valve body, a valve body cavity, a gate valve groove and a downstream valve body. The upstream valve body and A gate plate and a sealing device perpendicular to the axial direction of the valve body are arranged between the downstream valve bodies; the sealing device includes a cylindrical valve seat support with the same inner diameter and the outer diameter increases from upstream to downstream in the groove of the inner wall of the middle cavity of the valve body. Ring and the front cover, packing ring, spring support seat, spring and back cover which are successively arranged in the gap between the valve seat support ring and the cavity groove of the valve body along the direction from upstream to downstream; The axial direction of the valve body is vertical.

[0144] The valve cover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com