A flue gas heat exchanger and online cleaning method thereof

A flue gas heat exchanger and heat exchange element technology, applied in indirect heat exchangers, heat exchanger types, regenerative heat exchangers, etc. The effect of fouling and clogging, continuous operation cycle extension, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

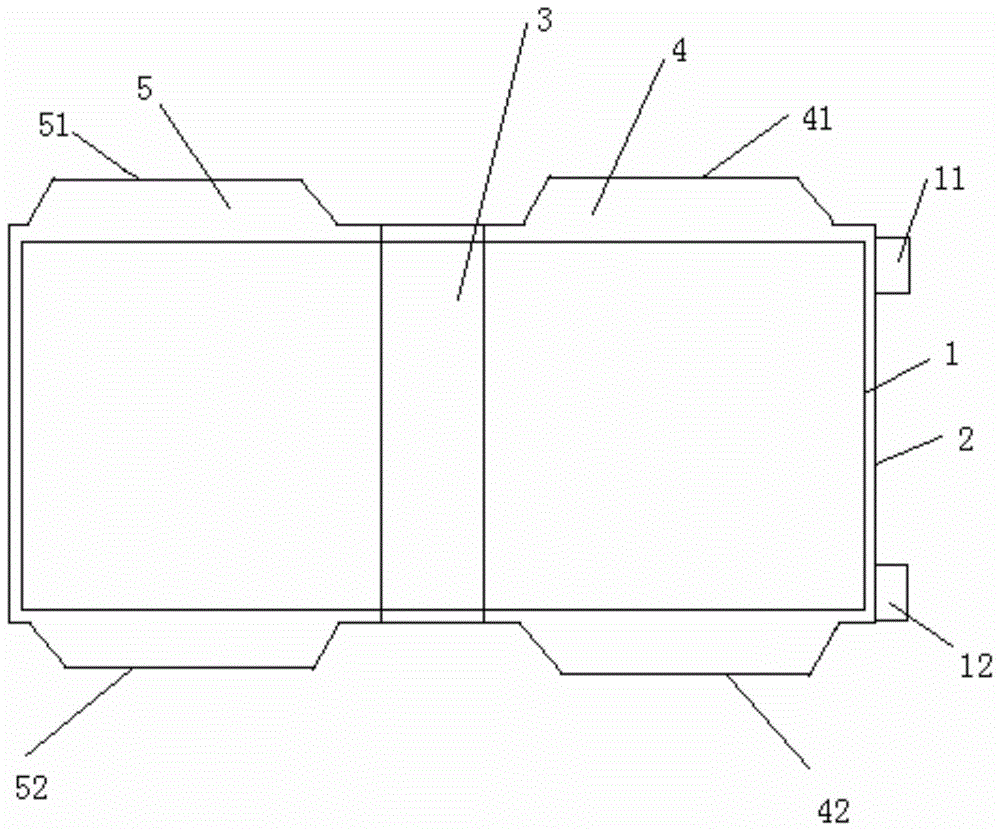

[0044] This embodiment is used to illustrate the flue gas heat exchanger and the online cleaning method of the flue gas heat exchanger according to the present invention.

[0045] The flue gas heat exchanger in this embodiment is as figure 1 As shown, the flue gas heat exchanger may include a rotor 1, a sealing area 3, an original flue 4 and a clean flue 5, and the original flue 4 and the clean flue 5 are separated by the sealing area 3 , the rotor 1 is provided with a heat exchange element, the original flue 4 and the clean flue 5 realize heat exchange through the heat exchange element on the rotor 1, the hot end of the original flue 4 and the cold end Each end is provided with a soot blower 11, 12, and the cold ends of the original flue 4 and the clean flue 5 are respectively provided with a cleaning device.

[0046] The flue gas heat exchanger is matched with the desulfurization system and runs continuously.

[0047] The online cleaning method of the present invention is ...

Embodiment 2

[0050] According to the flue gas heat exchanger in Embodiment 1, the difference is that the cold ends of the original flue 4 and the clean flue 5 are respectively provided with a cleaning device.

[0051] The flue gas heat exchanger is matched with the desulfurization system and runs continuously.

[0052] The online cleaning method of the present invention is used for online cleaning of the flue gas heat exchanger: use the soot blower 11 arranged at the hot end of the original flue 4 to blow the heat exchange element arranged on the rotor 1 with high-temperature steam , the conditions of the high-temperature steam purging may include: the pressure of the high-temperature steam is 2.0 MPa, the temperature of the high-temperature steam is 150° C., the flow rate of the high-temperature steam is 20 kg / min, and the high-temperature steam is purged once every 8 hours, The time of each blowing is 2h, 2 times a day; the heat exchange element arranged on the rotor 1 is blown with comp...

Embodiment 3

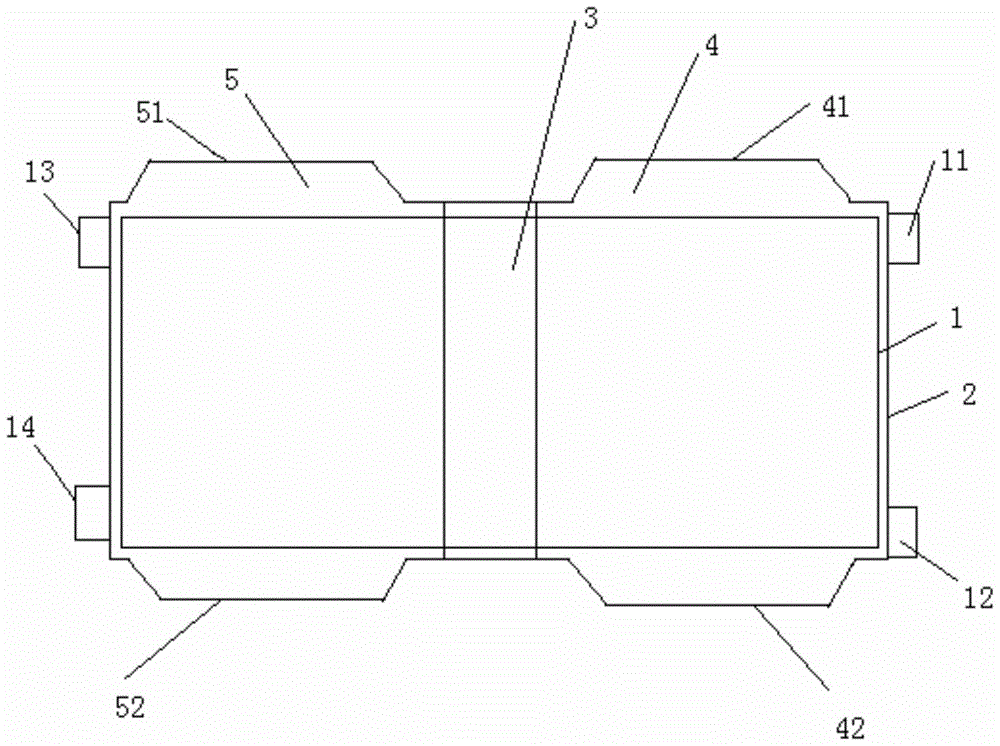

[0055] The flue gas heat exchanger of this embodiment is such as figure 2 As shown, the flue gas heat exchanger may include a rotor 1, a sealing area 3, an original flue 4 and a clean flue 5, and the original flue 4 and the clean flue 5 are separated by the sealing area 3 , the rotor 1 is provided with a heat exchange element, the original flue 4 and the clean flue 5 realize heat exchange through the heat exchange element on the rotor 1, the hot end of the original flue 4 and the cold end Each end is provided with a soot blower 11,12, and the hot end and the cold end of the clean flue are respectively provided with a soot blower 13,14, and the cold ends of the original flue 4 and the clean flue 5 are also respectively A cleaning device is provided.

[0056] The flue gas heat exchanger is matched with the desulfurization system and runs continuously.

[0057] Adopt the online cleaning method of the present invention to carry out the online cleaning of the flue gas heat excha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com