A fatigue lifetime measuring method for anisotropic material structural parts

An anisotropic and fatigue life technology, applied in the field of anisotropic materials for aero-engines and their structural parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

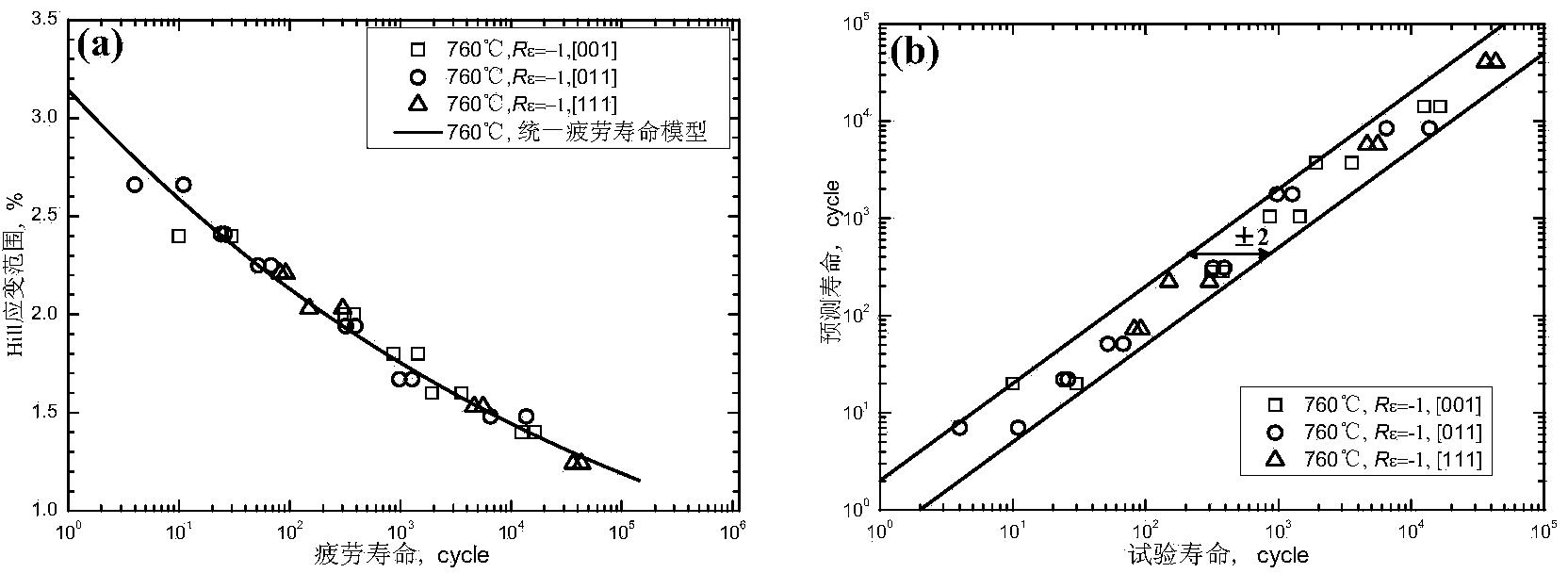

[0091] Example 1, the fatigue life measurement of the smooth sample of single crystal superalloy DD6, figure 1 Adopt technical scheme of the present invention to carry out the flowchart of life measurement process, its steps are:

[0092] 1. Carry out high temperature tensile and fatigue tests

[0093]For smooth samples of DD6 alloy, tensile and low-cycle fatigue tests on characteristic crystal orientations were carried out at a test temperature of 760°C. The high-temperature tensile test method is implemented according to the GB / T4338-1995 standard, and the low-cycle fatigue test method is implemented according to the GB / T15248-2008 standard. The elastic constants of the DD6 alloy [001] crystal-oriented smooth samples were obtained after high-temperature tensile tests, as shown in Table 1. The low-cycle fatigue test adopts the strain control method, the strain ratio is -1, and the strain rate is 5×10-3 / s. The corresponding fatigue life at the test strain level is obtained, ...

example 2

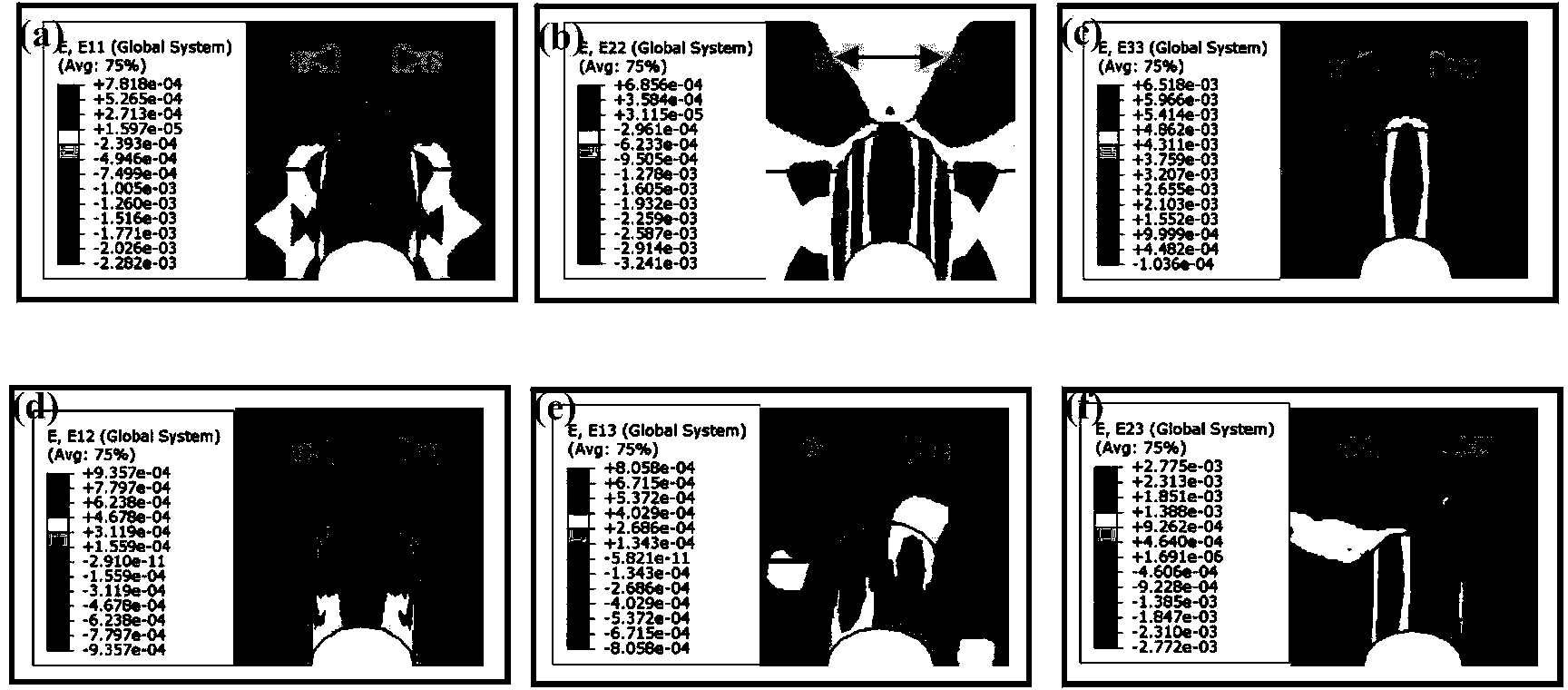

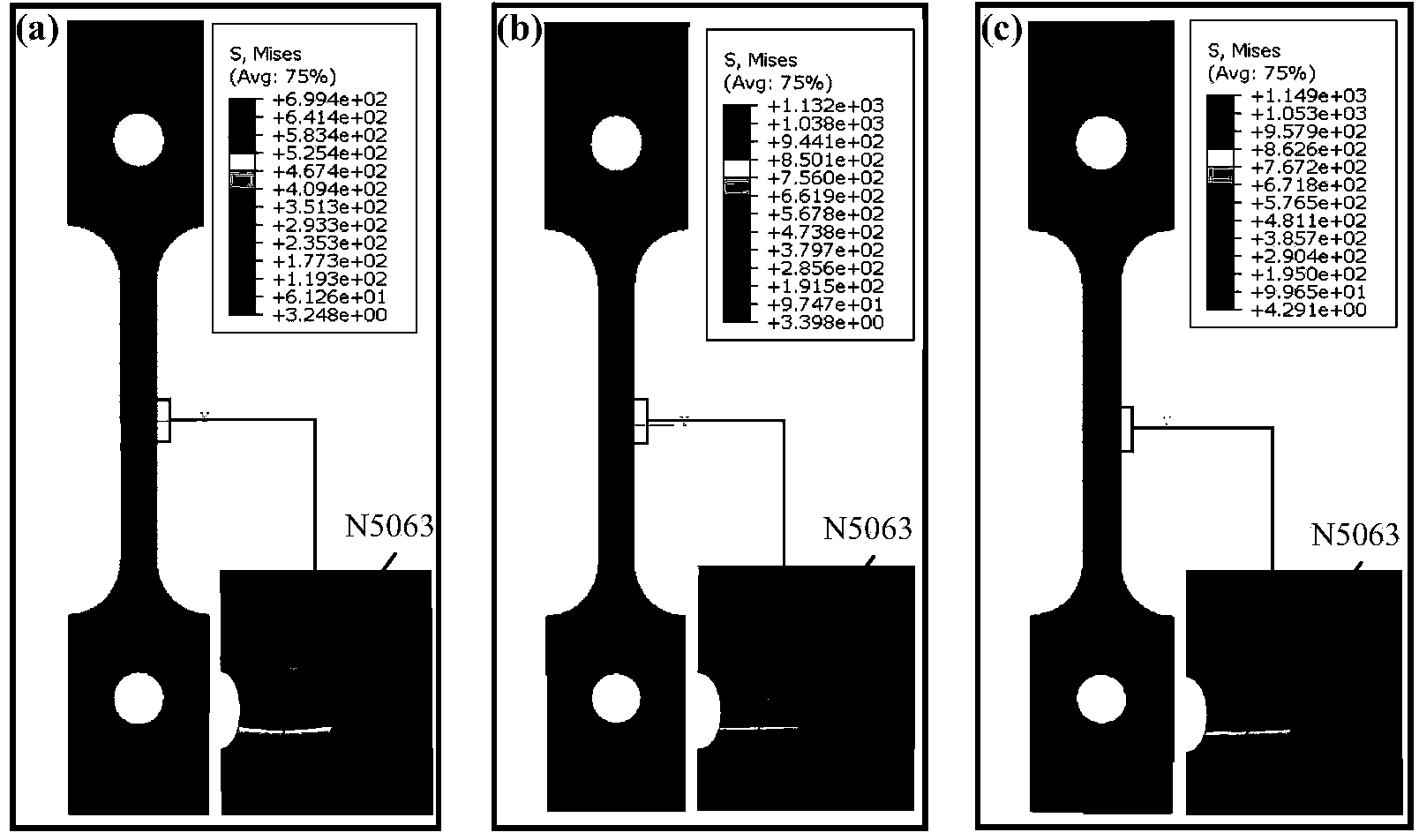

[0113] Example 2. Fatigue life measurement of single crystal superalloy DD6 thin plate structure with holes. DD6 thin plate structure with holes is mainly used to simulate the turbine blade assembly of aero-engine, and the 2mm thick sheet is used to simulate the thin-wall effect of the turbine blade assembly , the central circular hole is used to simulate the stress / strain concentration effect of the film cooling hole in the turbine blade assembly. The stress-strain finite element calculation, life modeling and measurement of thin plate structures with holes under fatigue loads have important guiding significance for the structural optimization design and mechanical behavior analysis of actual turbine blade components. figure 1 Adopt technical scheme of the present invention to carry out the flowchart of life measurement process, its steps are:

[0114] 1. Establish the finite element model of DD6 thin plate structure with holes

[0115] The geometric dimensions of DD6 thin p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com