Detection device for thermal reaction coke formation of heavy oil and online detection method using the device

A technology for reacting coke formation and detection device, applied in the field of electrical measurement, can solve the problems of online monitoring of coking performance, wrong judgment, misjudgment, etc., and achieve the effect of avoiding economic loss, accurate judgment, and avoiding pipeline blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

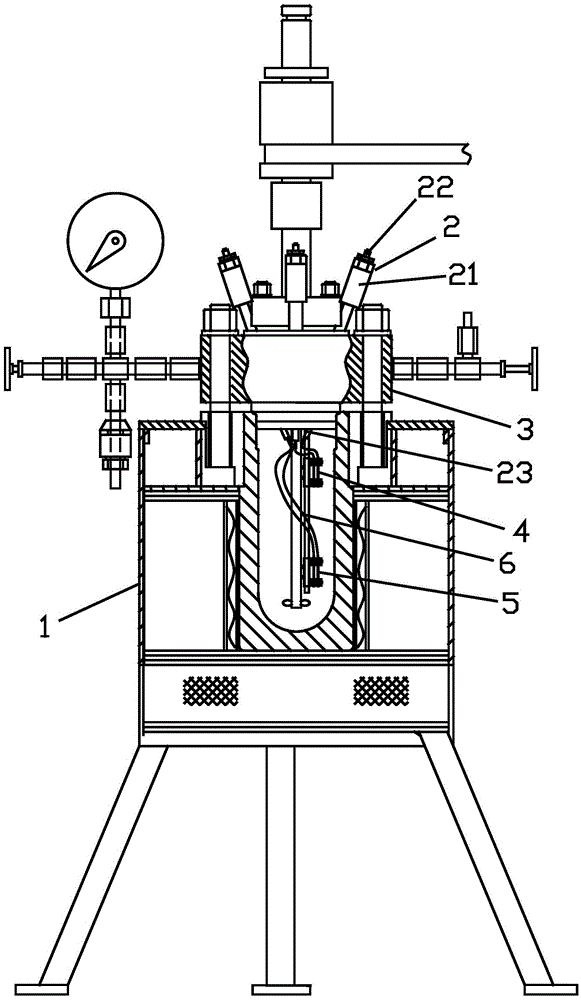

[0017] The detection device for heavy oil thermal reaction coke of the present invention is installed in a reaction kettle 1 and includes an electrode plate and an electrode terminal 2 .

[0018] There are four electrode terminals 2, all of which are installed on the kettle cover 3 of the reaction kettle 1.

[0019] The electrode terminal 2 includes a column body 21 , an upper pole 22 is installed on the top of the column 21 , and a lower pole 23 is installed on the bottom of the column 21 .

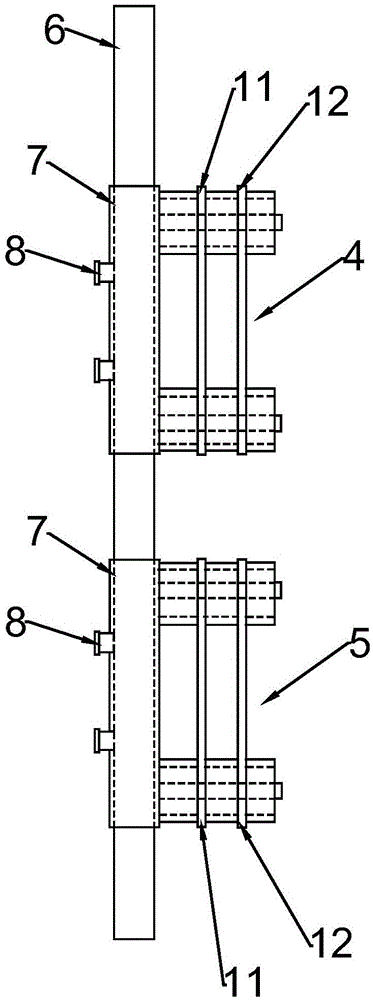

[0020] The electrode pads include an upper electrode pad 4 and a lower electrode pad 5 , and both the upper electrode pad 4 and the lower electrode pad 5 include a left electrode 11 and a right electrode 12 .

[0021] The kettle cover 3 of the reaction kettle 1 is vertically equipped with a support bar 6 , the top of the support bar 6 is connected with the kettle cover 3 , and the upper electrode plate 4 and the lower electrode plate 5 are all installed on the support bar 6 .

[0022] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com