Method for increasing yield of stripping technology

A technology of stripping process and yield rate, which is applied in the field of photolithography process, can solve the problems of metal residue on the surface of photoresist, and achieve the effect of complete reaction, improved yield rate and sufficient reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

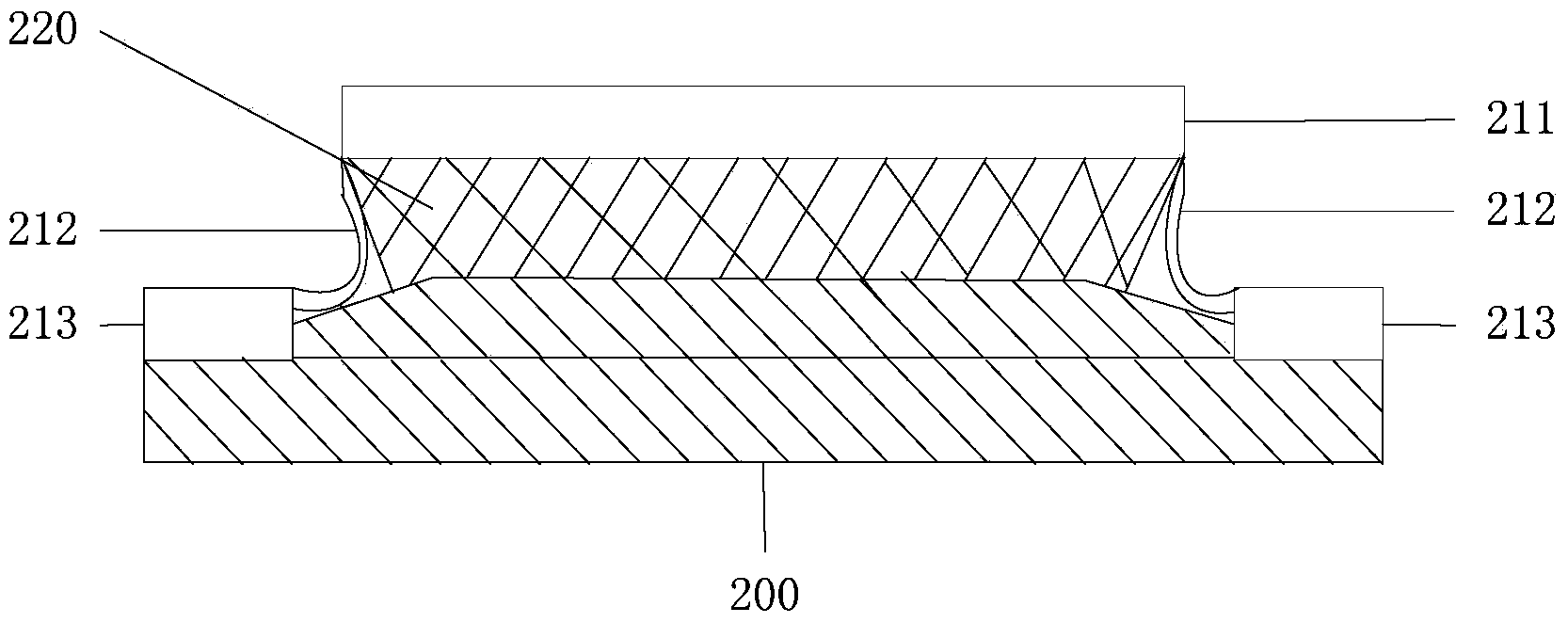

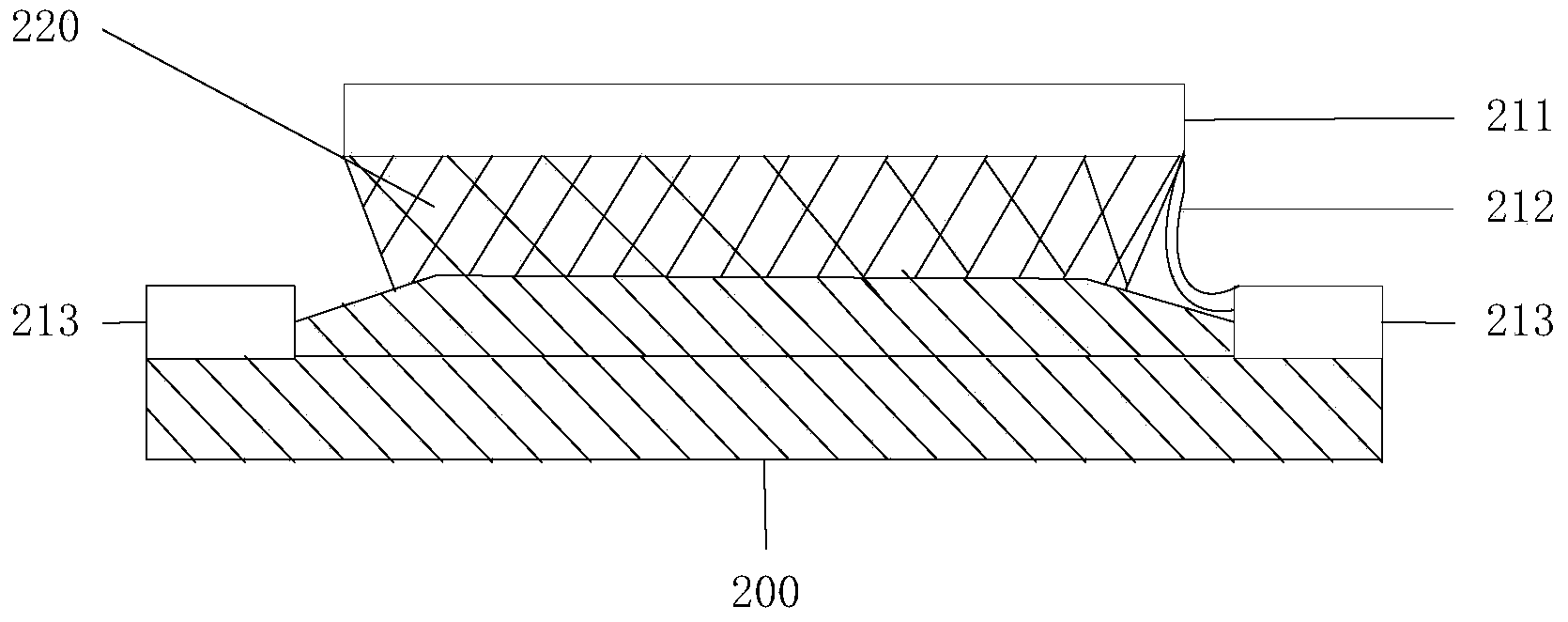

[0027] As mentioned in the background section, in the current lift-off process, especially when there are steps on the substrate surface, the metal on the photoresist surface is not removed cleanly, which reduces the yield of the lift-off process. The inventors found that after metal deposition, a thin layer of metal connection is formed on the side of the photoresist, which will affect the contact reaction between the immersion solution and the photoresist, resulting in metal residues, thereby reducing the yield of the stripping process.

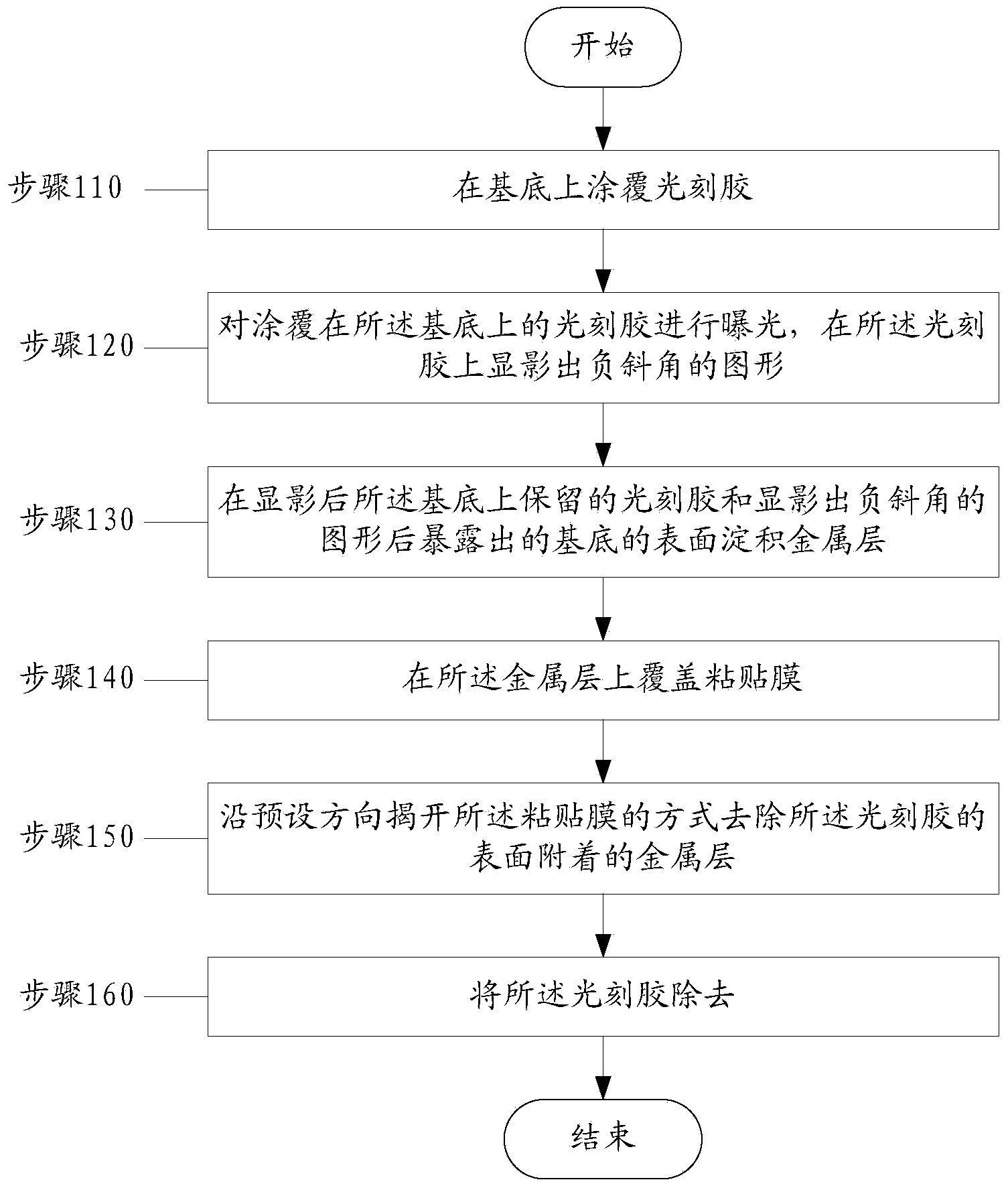

[0028] Based on the above research, an embodiment of the present invention provides a method for improving the yield of the stripping process, the method includes: coating a photoresist on the substrate; exposing the photoresist coated on the substrate, and A pattern with a negative bevel is developed on the photoresist; a metal layer is deposited on the photoresist remaining on the substrate after development and the surface of the substrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com