Method for controlling flowing of magnetic liquid

A technology of magnetic liquid and flow direction, applied in control/adjustment system, adjustment of magnetic variable, instruments, etc., can solve the problems of practical application, wear and blockage of fluids that limit the addition of suspended particles, and achieve a wide range of scientific and applied value and methods. Unique, structurally novel effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

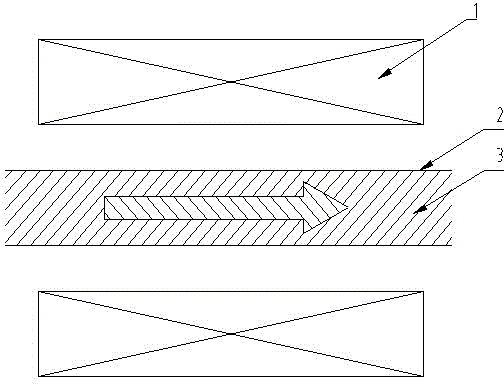

[0014] like figure 1 As shown, a method for controlling the flow of a magnetic fluid comprises the following steps:

[0015] a. The magnetic field generating device 1 is symmetrically arranged on both sides of the channel container 2, and the magnetic liquid 3 is placed in the channel container 2;

[0016] b. The magnetic field generating device 1 generates a gradient magnetic field, and adjusts the gradient direction of the gradient magnetic field. When the gradient direction of the gradient magnetic field generated by the magnetic field generating device 1 is the same as the flow direction of the magnetic liquid 3, the magnetic nanoparticles in the magnetic liquid 3 flow under the action of magnetic force. Speed up; when the gradient direction of the gradient magnetic field generated by the magnetic field generating device 1 is opposite to the flow direction of the magnetic liquid 3, the flow speed of the magnetic nanoparticles in the magnetic liquid 3 will be slowed dow...

Embodiment 2

[0019] The embodiment of this embodiment is basically the same as that of Example 1, the difference is that:

[0020] In this embodiment, the magnetic field generator 1 is powered by an AC power supply, and the magnetic liquid 3 is oil-based FeSO 4 magnetic fluid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com