Multi-objective sensor distributed point optimizing method on basis of self-adaptive differential evolution

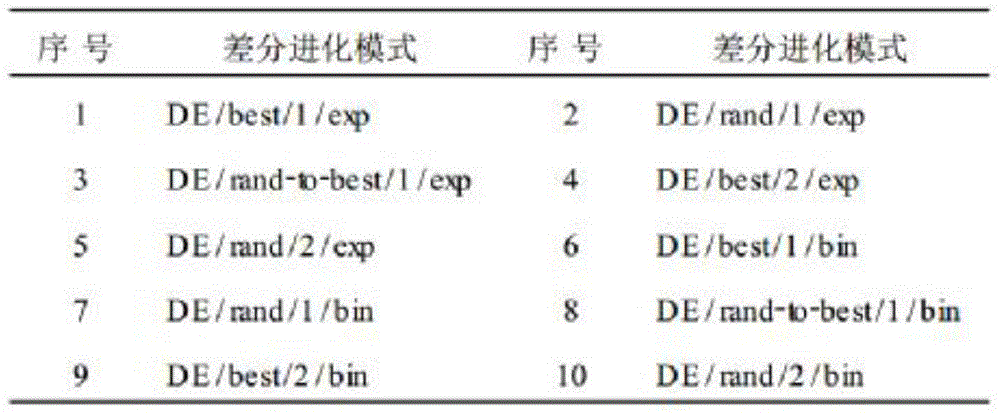

An adaptive difference and sensor technology, applied in the direction of instruments, special data processing applications, electrical digital data processing, etc., can solve the problems of single criterion for sensor layout optimization, insufficient local search ability, inaccessibility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

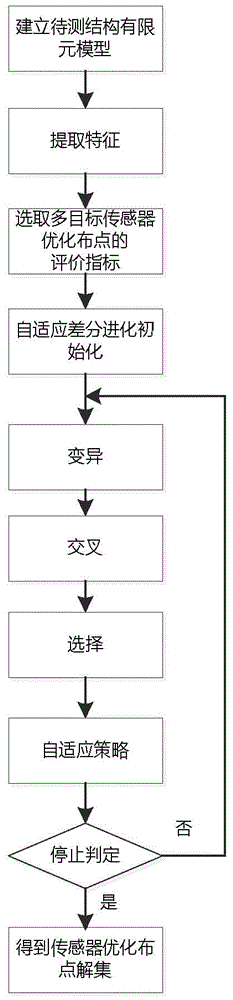

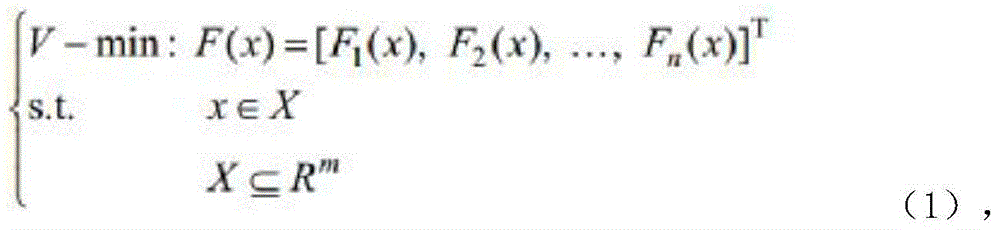

[0036] Problem to be solved: For a specific structure, there are n degrees of freedom in total, and there are m sensors (n figure 2 The steps of the method of the present invention shown and described can be calculated.

[0037] (1) Structure multi-target sensor optimization point layout preprocessing:

[0038](1.1) Establish the finite element model of the structure to be tested, use the numerical solution method to obtain the dynamic characteristic data of the structure, and extract the mode shape matrix of all candidate measuring points. All the measuring point positions contained in each mode shape are taken as candidate resources for optimal arrangement. The mode shape data of the structure is required for the following calculations, and its dynamic characteristics must be obtained according to the finite element analysis software. For example, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com