Modularization fast mounted finished product door head and installation technology thereof

An installation process and modular technology, applied in display devices, signs, instruments, etc., can solve problems such as adverse effects of traffic and urban management, inability to build store revenue, unreliable welding strength, etc., and achieve high dimensional accuracy and ingenious structure of finished products , using flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

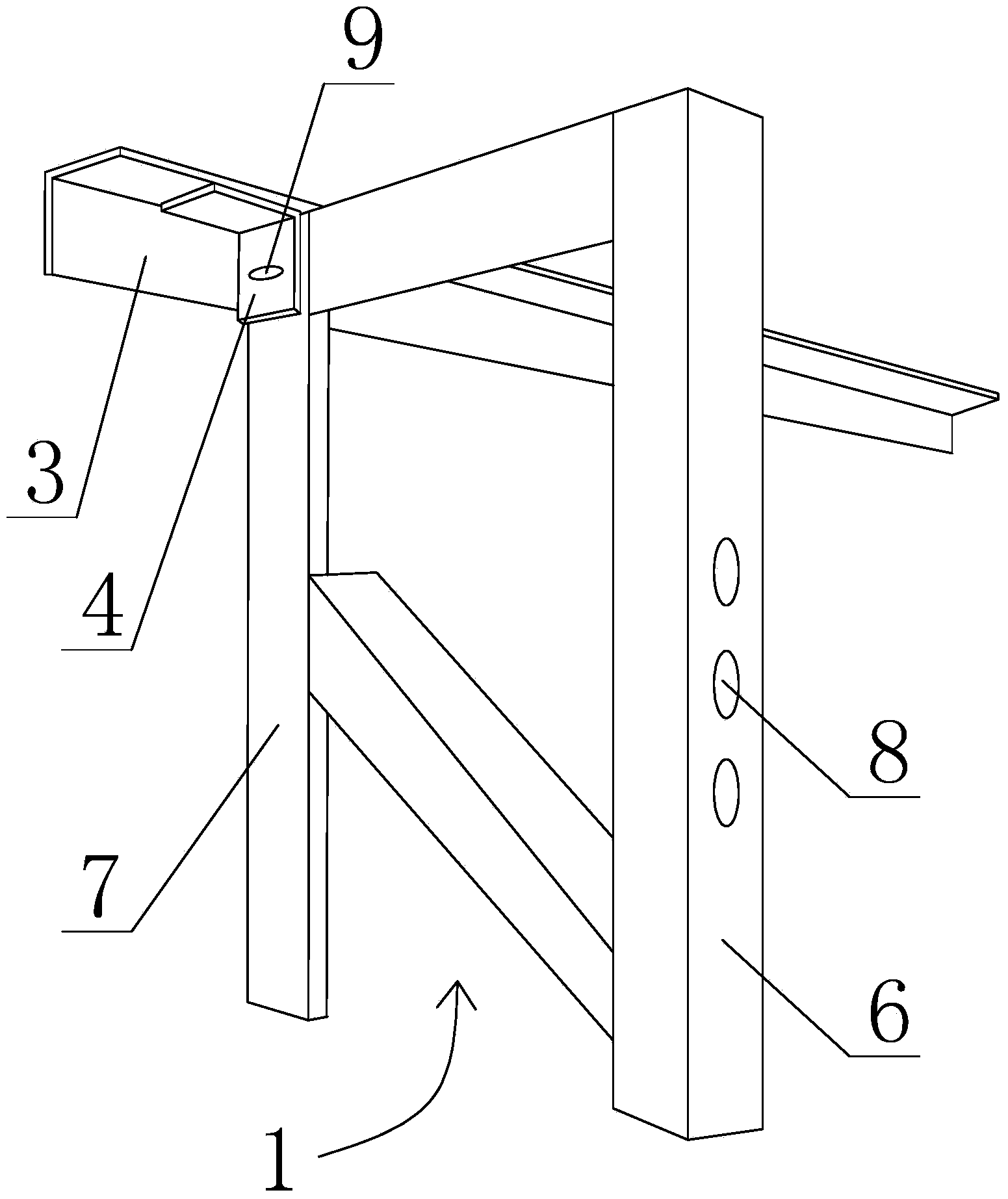

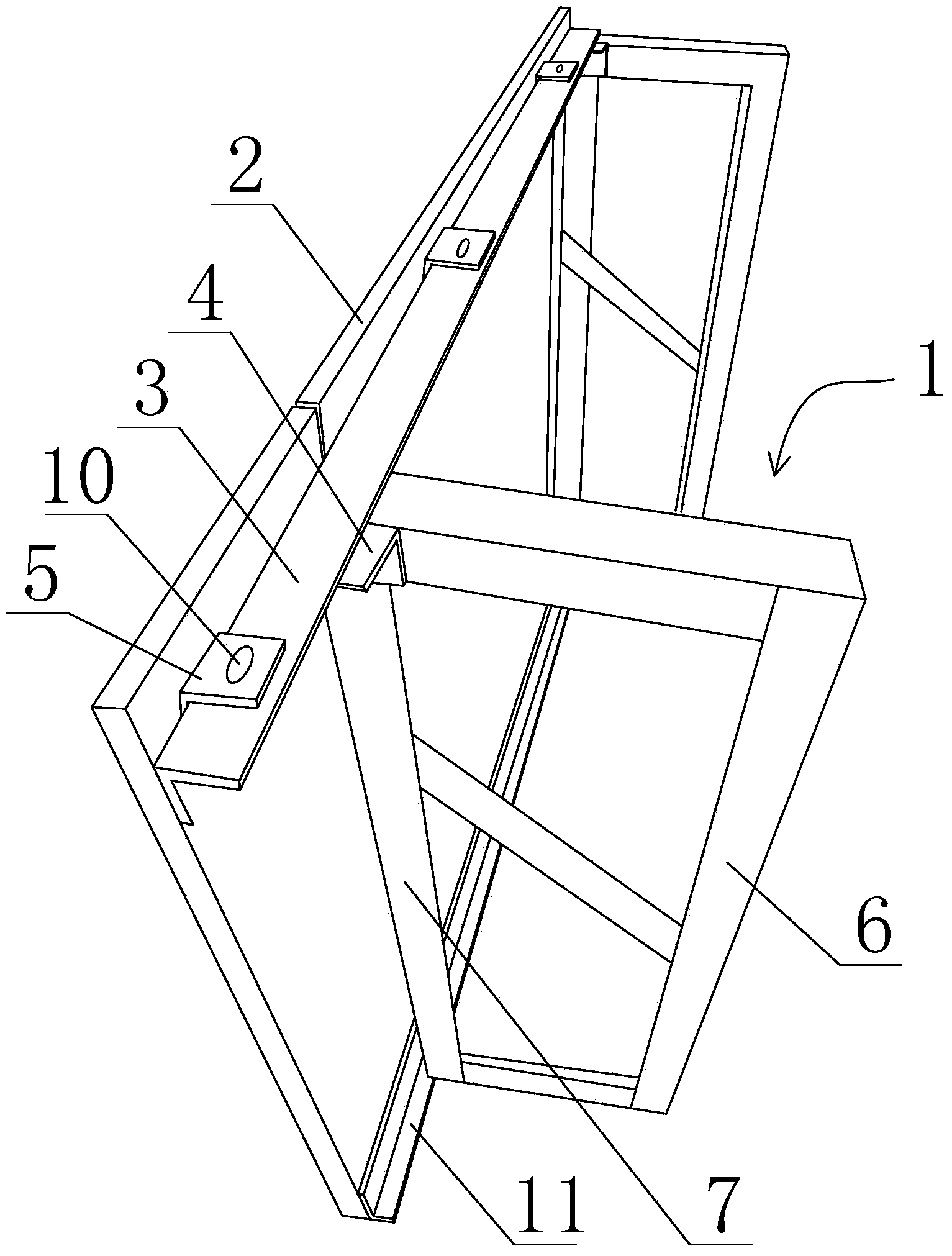

[0031] like figure 1 , 2 As shown, the modular quick-installed finished door head of this embodiment includes several mutually independent brackets 1 (the number of brackets is determined according to the length of the door head, and a bracket is generally arranged at a distance of 1300mm-1800mm), a panel 2, an upper beam 3, The lower beam 11, the adjustment code 4 and the hanging code 5 fixed on the back of the panel 2. The number of panels need not equal the number of spaces between brackets.

[0032] Wherein, the bracket 1 has a rear column 6 fixed to the wall and a front column 7 for fixing the panel 2, and the rear column 6 is provided with a vertical oblong hole 8 to realize the vertical adjustment of the bracket 1.

[0033] The adjustment code 4 has a vertical plate and a supporting surface, and the adjustable code 4 is fixed on the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com