Sealant encapsulation structure of automotive electronic elements and sealant sealing method thereof

An electronic component and glue sealing technology is applied in the structural field of automotive electronic component sealant encapsulation modules, which can solve the problems of increased manufacturing difficulty, leakage failure, and high design requirements, and achieves simple manufacturing and assembly process, guaranteed installation position, and simplified structure. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

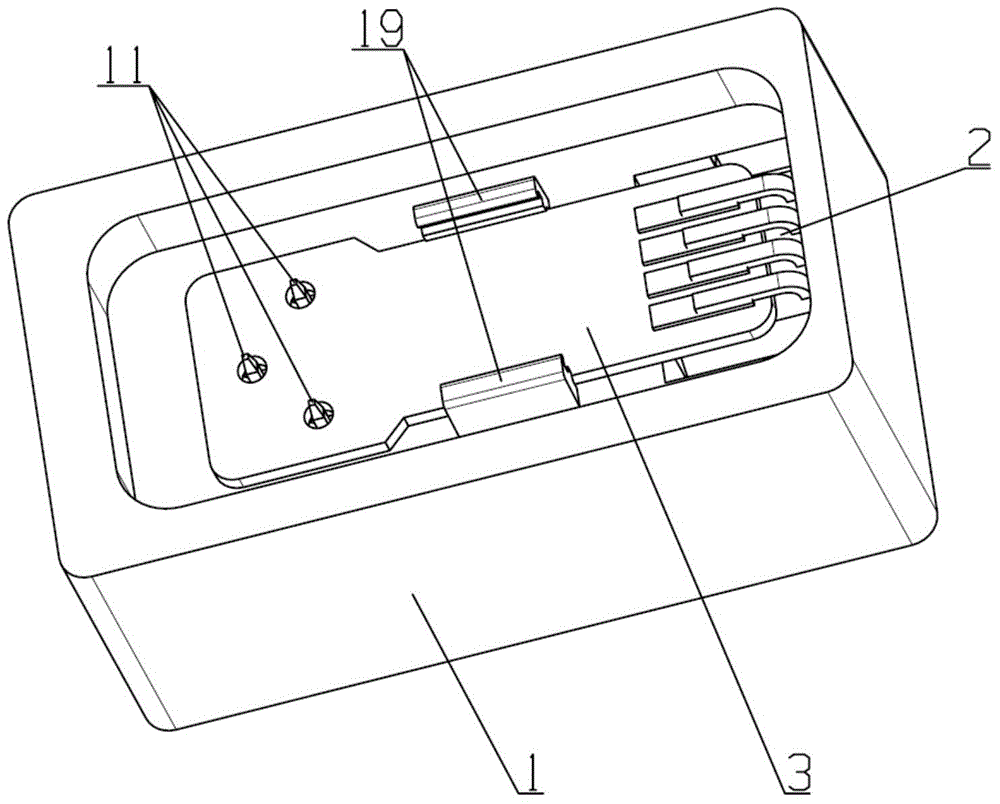

[0047] The sealant encapsulation structure of the vehicle electronic component provided by the present invention, such as figure 2 As shown, it includes a main body 1 , a chip 2 (in this embodiment, a Hall chip is taken as an example for illustration) and a circuit board 3 .

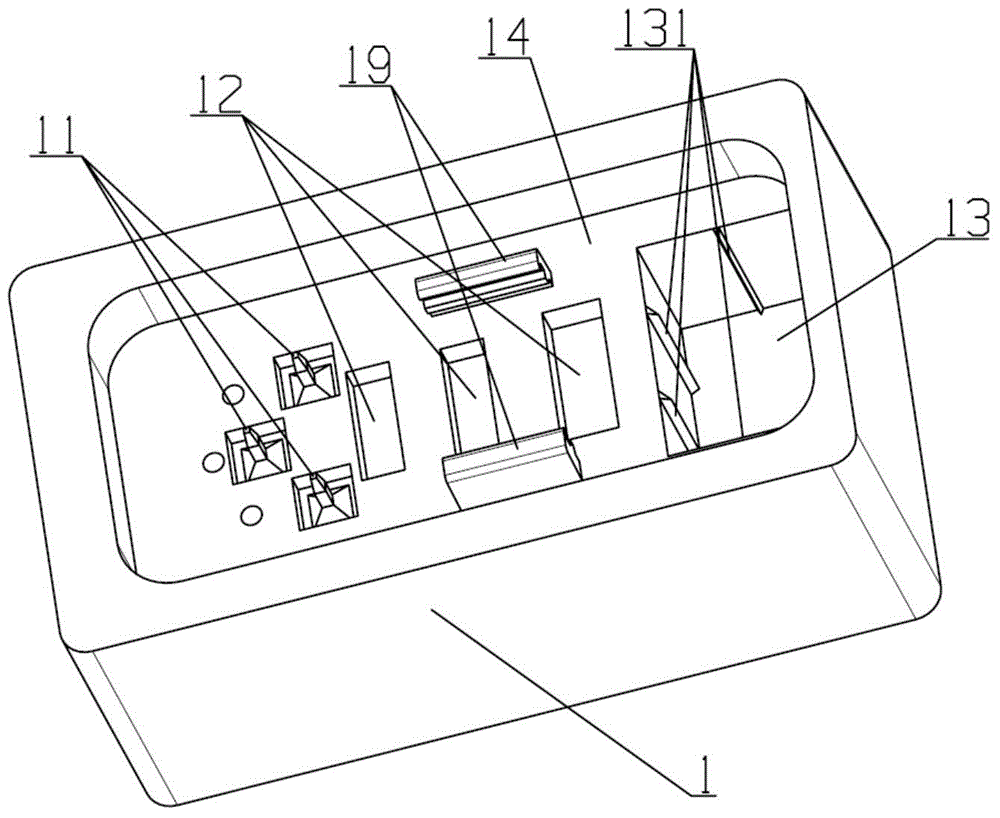

[0048] Such as image 3As shown, the main body 1 is packaged with a PIN pin set 11 by injection molding. The main body 1 is formed with a cavity 14 , and an electronic element cavity 12 and a chip cavity 13 are formed in the cavity 14 . In this embodiment, there are three electronic component cavities 12 and one chip cavity 13 in the concave cavity 14 .

[0049] The chip 2 has a sensor element 21 and a chip PIN pin group 22, such as Figure 4 shown. In this embodiment, taking the sensing element 21 located at the head of the chip 2 as an example, the fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com