LED filament

A LED filament and chip technology, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of blue leakage of filament devices, large amount of materials, high cost, etc., achieve the effect of no leakage and reduce material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

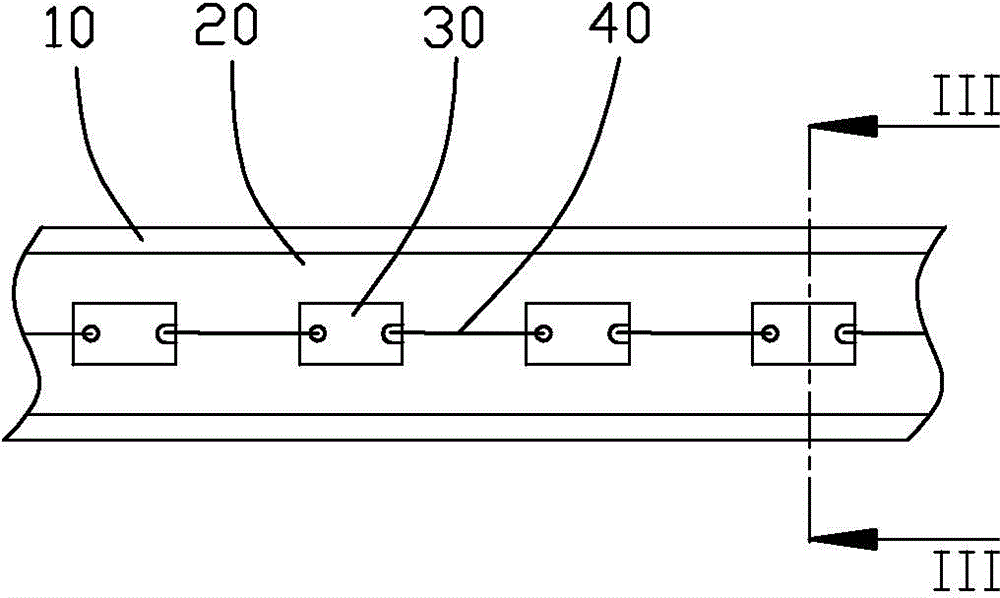

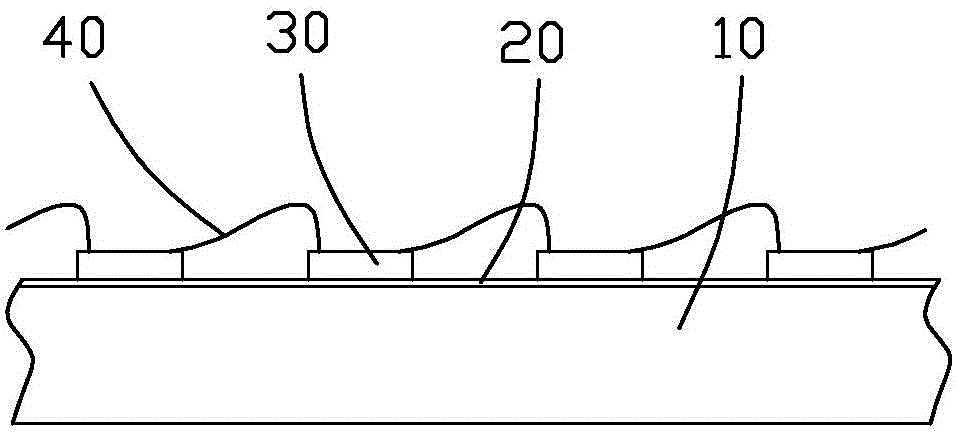

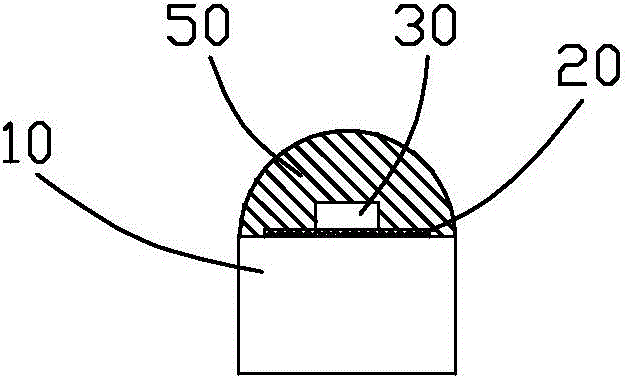

[0015] like figure 1 , figure 2 ,and image 3 As shown, the LED filament of the present invention includes a substrate 10 , a fluorescent glue layer 20 , an LED chip 30 , a wire 40 , and a fluorescent glue coating layer 50 .

[0016] The substrate 10 can be a transparent substrate made of sapphire, high polymer, ceramics or glass, etc., and the fluorescent adhesive layer 20 is formed on the side of the substrate 10 used for crystal bonding by physical and chemical methods. Adhesive layer 20 is a mixture of silica gel, epoxy resin or other viscous substances and fluorescent powder, with a thickness of more than 0.03mm, and its area may be equal to or smaller than the area of one side of the substrate 10 for die bonding, so as to completely or partially cover the substrate 10 for die bonding side. In this embodiment, the area of the fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com