Four-wire three-head full-automatic terminal pressing machine

A terminal crimping machine and terminal crimping technology, applied in the direction of line/collector parts, electrical components, circuits, etc., can solve the problems of unsatisfactory production quality, low production efficiency, high labor cost, etc., to improve production efficiency and The effect of market competitiveness, high production efficiency and low labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

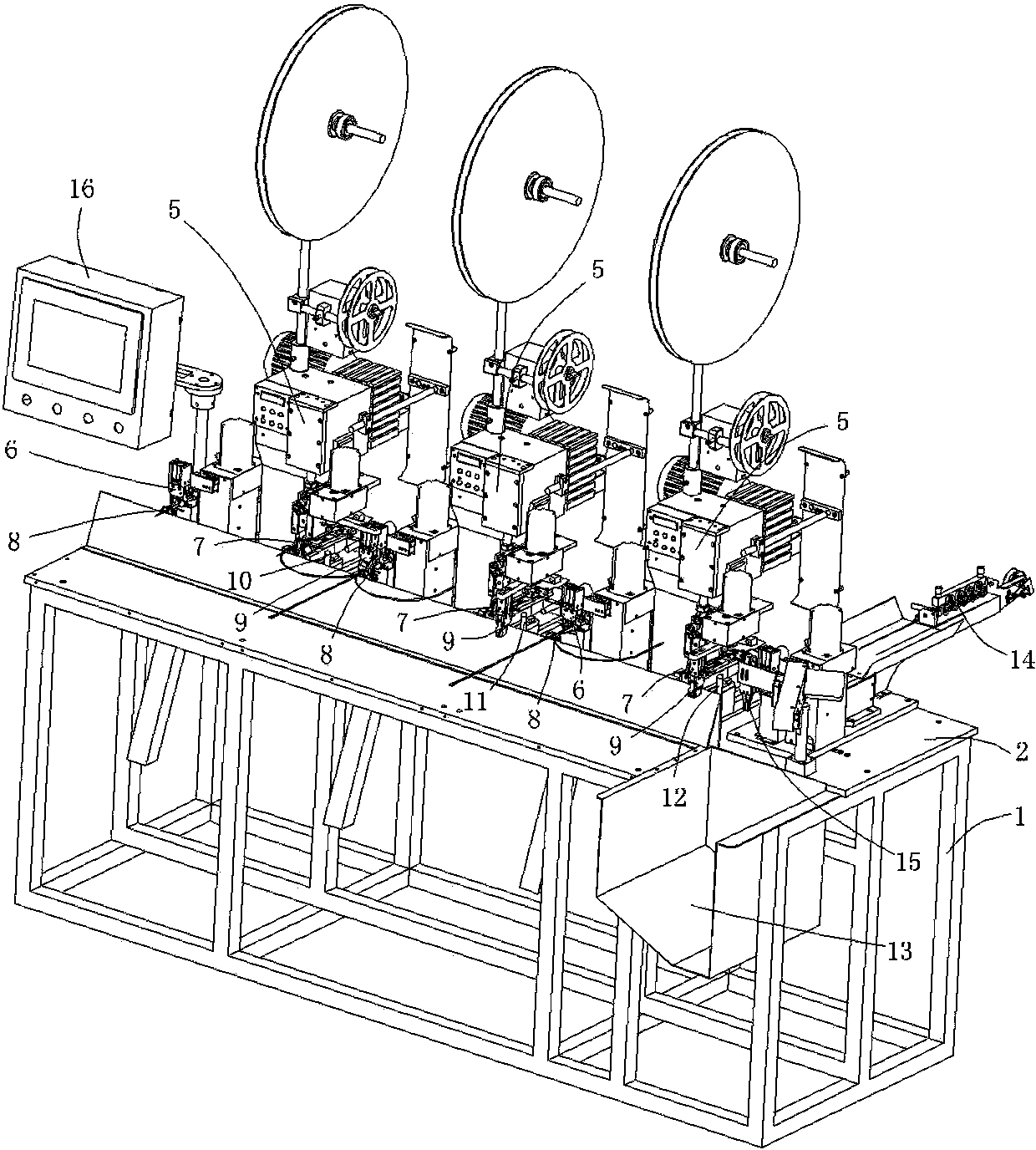

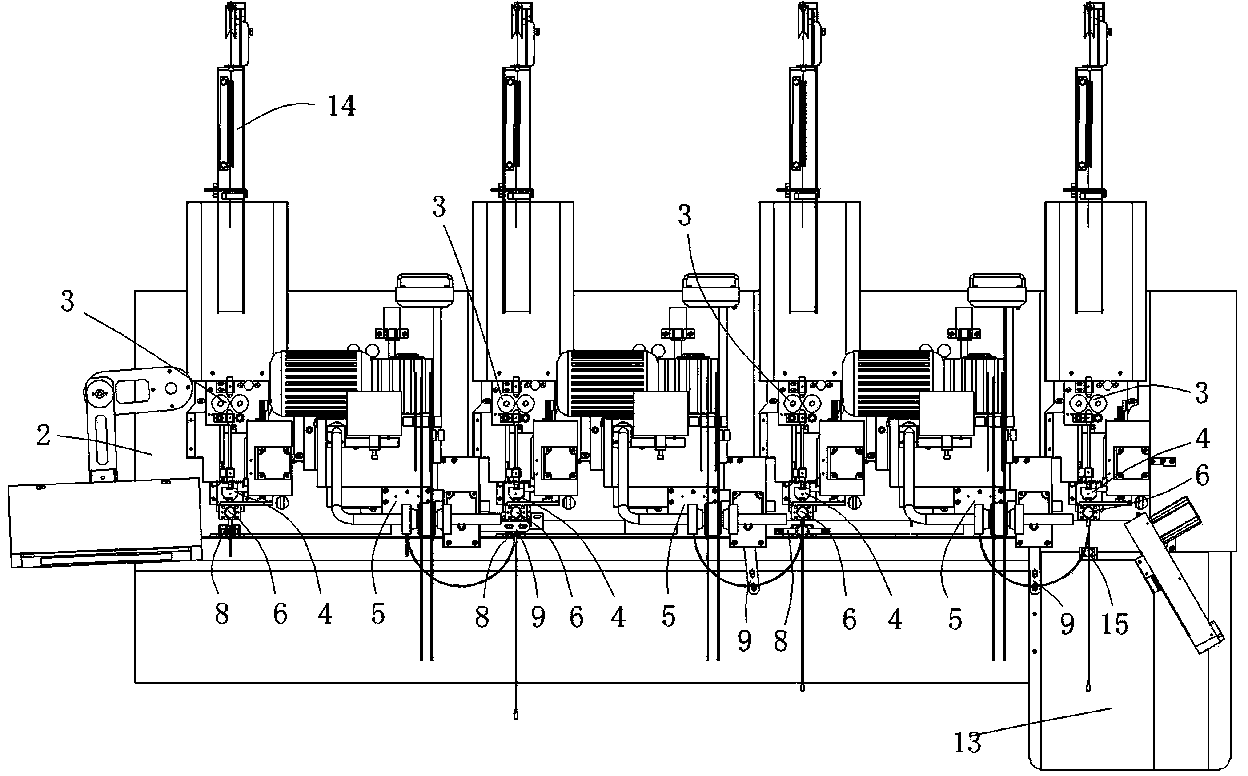

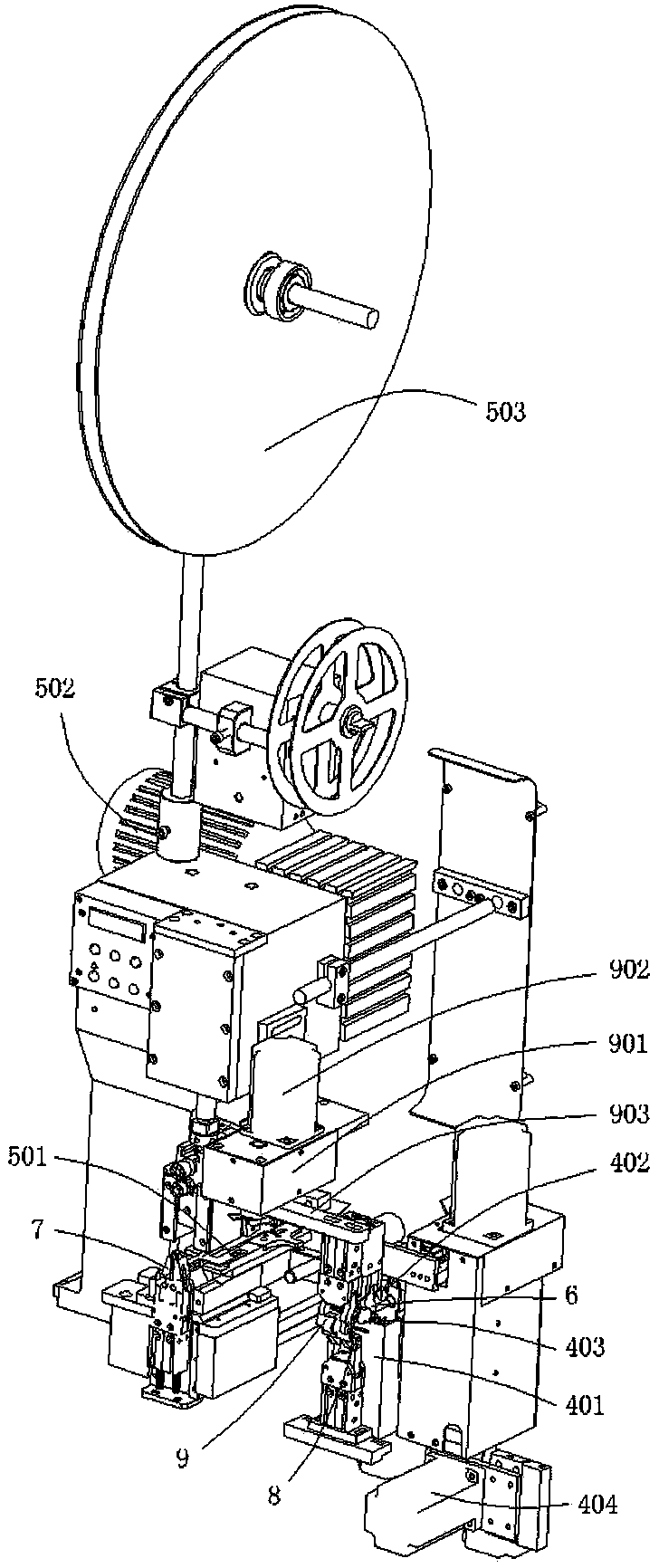

[0028] refer to Figure 1~Figure 6 , a four-wire three-head automatic terminal crimping machine, including a machine base 1, a workbench 2 set on the machine base, four workbenches are arranged side by side for conveying four kinds of the same size or Wire feeding devices 3 for cables of different sizes, each of the wire feeding devices 3 is provided with a wire cutting and stripping device 4 for stripping and cutting the corresponding cables, adjacent to the wire cutting and stripping device A terminal crimping device 5 is provided between them;

[0029]The front of each said wire cutting and stripping device 4 is provided with a drawing manipulator 6 that pulls the corresponding cable forward. The front side of the drawing manipulator is fixed with a guide hook 601 . A doubling manipulator 7, between the doubling manipulator and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com