Split type stator structure

A stator structure, split technology, applied in the shape/style/structure of winding conductor, magnetic circuit shape/style/structure, shape/style/structure of winding insulation, etc., can solve the problem of low work efficiency, troublesome winding, etc. Obstructing motor performance and other problems, to achieve the effect of improving production efficiency, reducing defective rate and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to enable the examiner to further understand the structure, features and other purposes of the present invention, the attached preferred embodiments are attached with accompanying drawings in detail as follows. The embodiments illustrated in the accompanying drawings are only used to illustrate the technical solution of the present invention , not to limit the present invention.

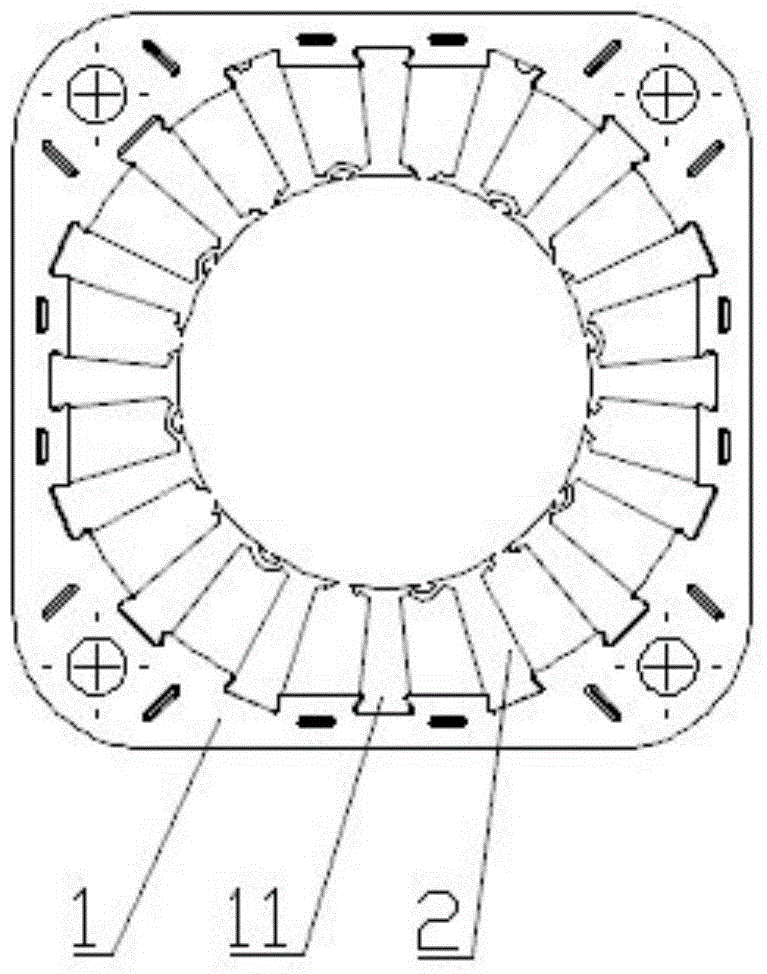

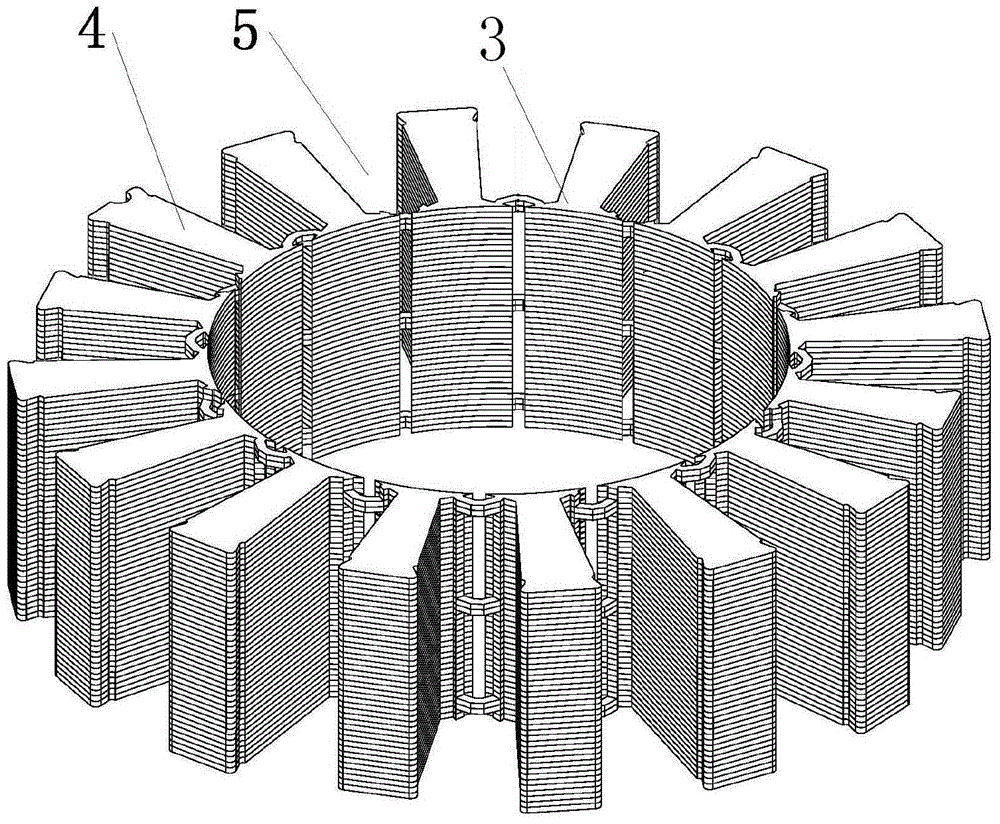

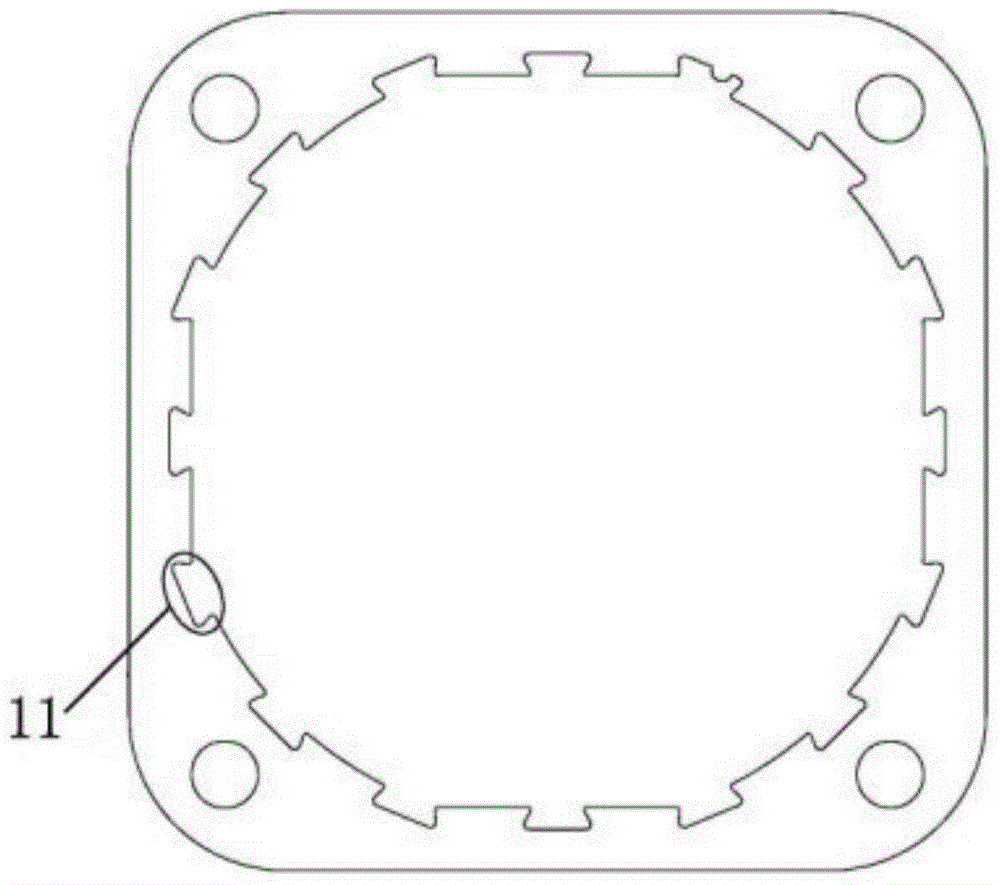

[0025] like Figure 1 to Figure 3 As shown, the present invention provides a split stator structure, including an outer ring stator 1 and an inner ring stator 2 sleeved inside the outer ring stator 1 . like figure 2 , image 3 As shown, the inner ring stator 2 is composed of an even number of original line slot yokes 3, and two adjacent original line slot yokes 3 are electrically connected by spaced pole jumps, and each original line slot yoke 3 Convex teeth 4 are evenly arranged in the circumferential direction, and wire slots 5 are formed between adjacent convex teeth 4. The ann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com