Warming clothes with high color degree

A color and clothing technology, applied in the field of clothing, can solve the problems of sewing process and wearing experience risks, clothing cannot be used for two purposes, and the fabric elasticity is not good, so as to achieve light weight, improved thermal performance, and enhanced velvet resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

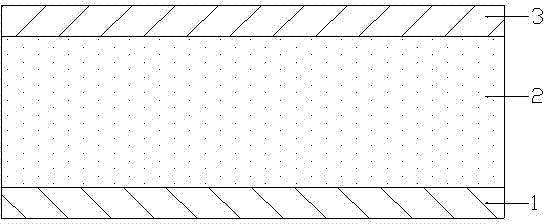

[0023] see figure 1 , the present invention relates to a warm garment with high luster, comprising a back fabric 3 with strong reflectivity on the outer layer and a front fabric 1 with weak reflectivity on the inner layer, which can be turned over and reversed, and the difference between the back fabric 3 and the front fabric 1 A thermal insulation layer 2 is arranged between.

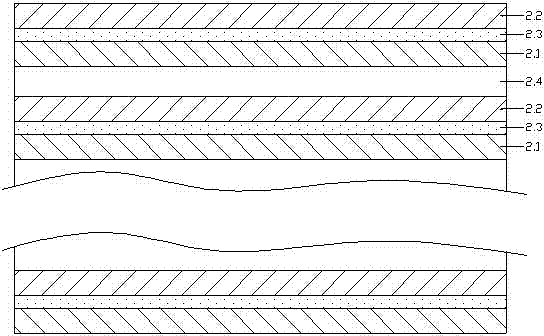

[0024] see figure 2 , the thermal insulation layer 2 includes an inner layer fabric 2.1 having a single layer of high-count high-density fabric and an outer layer fabric 2.2 of a single-layer high-count high-density fabric, and there is a gap between the inner layer fabric 2.1 and the outer layer fabric 2.2. Adhesive sections 2.3 arranged at intervals parallel to each other and with a width of 2mm-15mm, the inner layer fabric 2.1 and the outer layer fabric 2.2 at the adhesive section 2.3 are bonded together, and the inner layer fabric between adjacent adhesive sections 2.3 A filling space 2.4 is for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com