Paper pulp stirring paddle

A stirring paddle and pulp technology, applied in the direction of mixer accessories, dissolving, mixer, etc., can solve the problems of affecting the service life of the motor, large motor load, large resistance, etc., and achieve the effect of prolonging the service life, reducing compliance and reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific implementation manners of the present invention will be briefly described below in conjunction with the accompanying drawings.

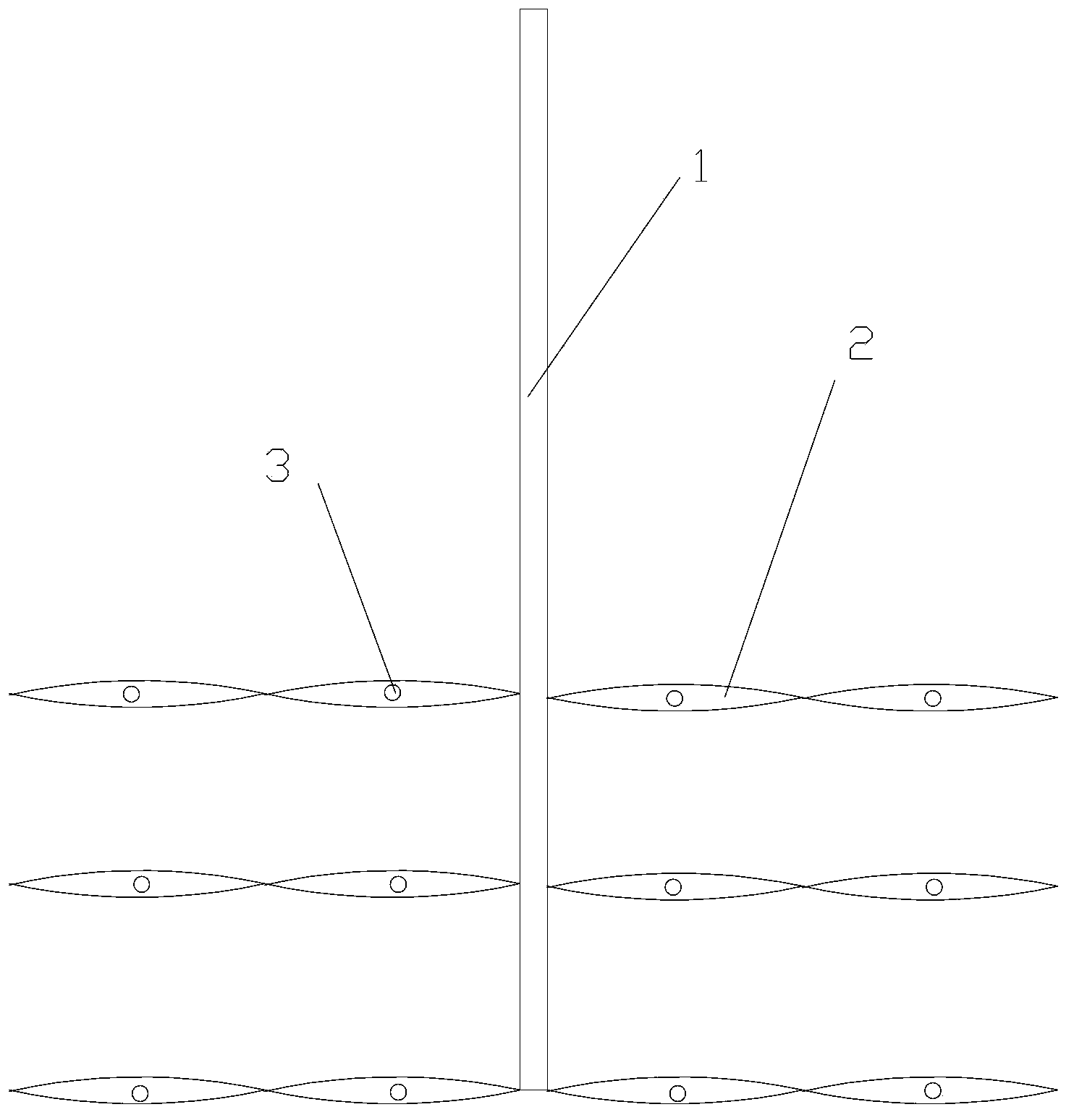

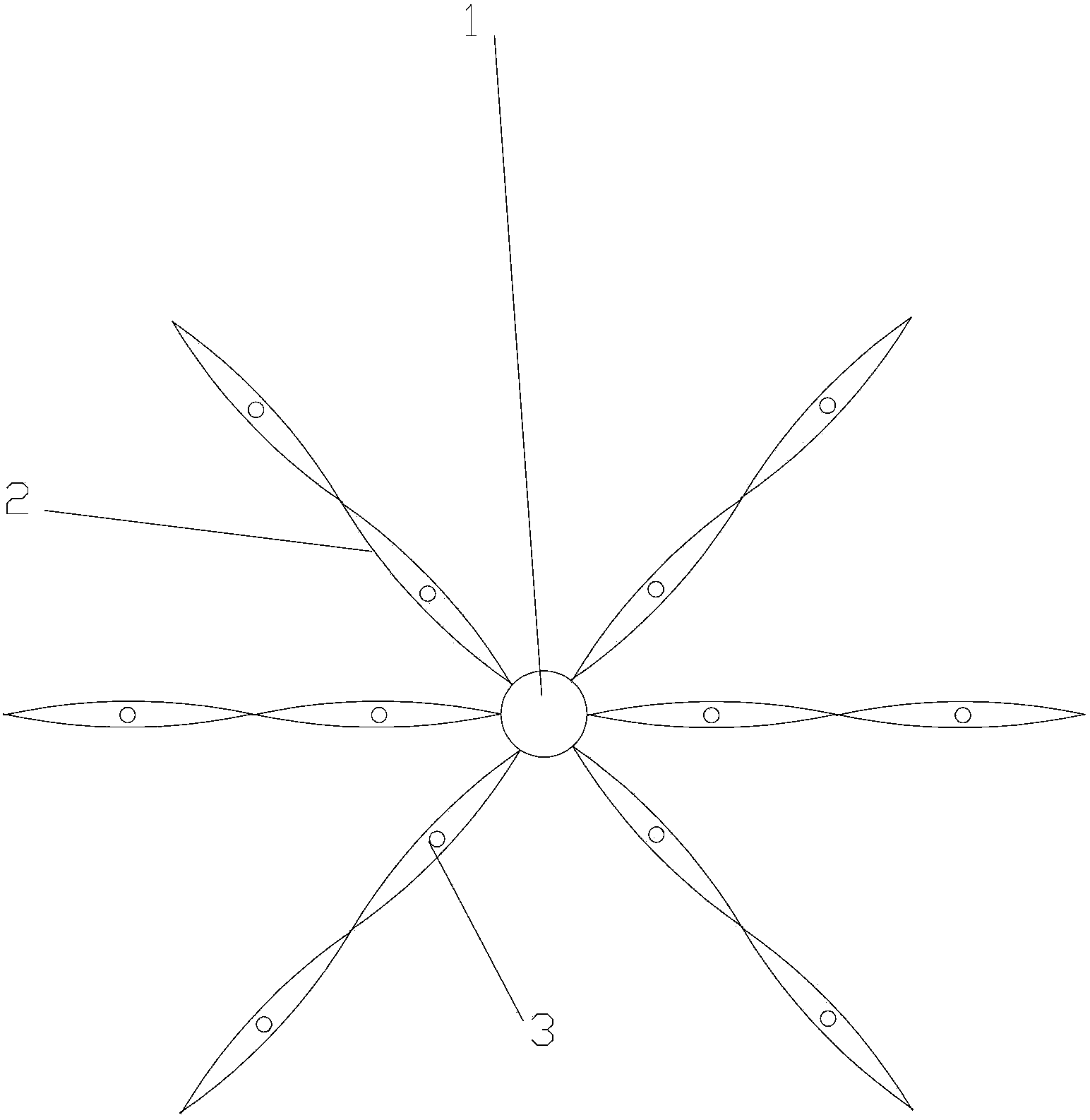

[0014] Such as figure 1 , figure 2 As shown, the pulp stirring paddle includes a rotating shaft 1 and several paddles 2, and the paddles 2 are fixed on the rotating shaft 1, and the paddles 2 are helical, and any one of the paddles 2 is provided with a Hole 3, the surfaces of the paddle 1 and the rotating shaft 1 are glazed or provided with a ceramic outer layer, and the through hole 3 is circular.

[0015] An embodiment of the present invention has been described in detail above, but the content described is only a preferred embodiment of the present invention, and cannot be considered as limiting the implementation scope of the present invention. All equivalent changes and improvements made according to the application scope of the present invention shall still belong to the scope covered by the patent of the present inventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com