Automobile safety air bag steel pipe production line

A technology of automobile safety and production line, which is applied to vehicle parts, feeding devices, positioning devices, etc., can solve the problems of low automation, high manual labor intensity, low automation of loading and unloading, etc., and achieve the prevention of safety accidents and high automation , Reduce the effect of manual labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

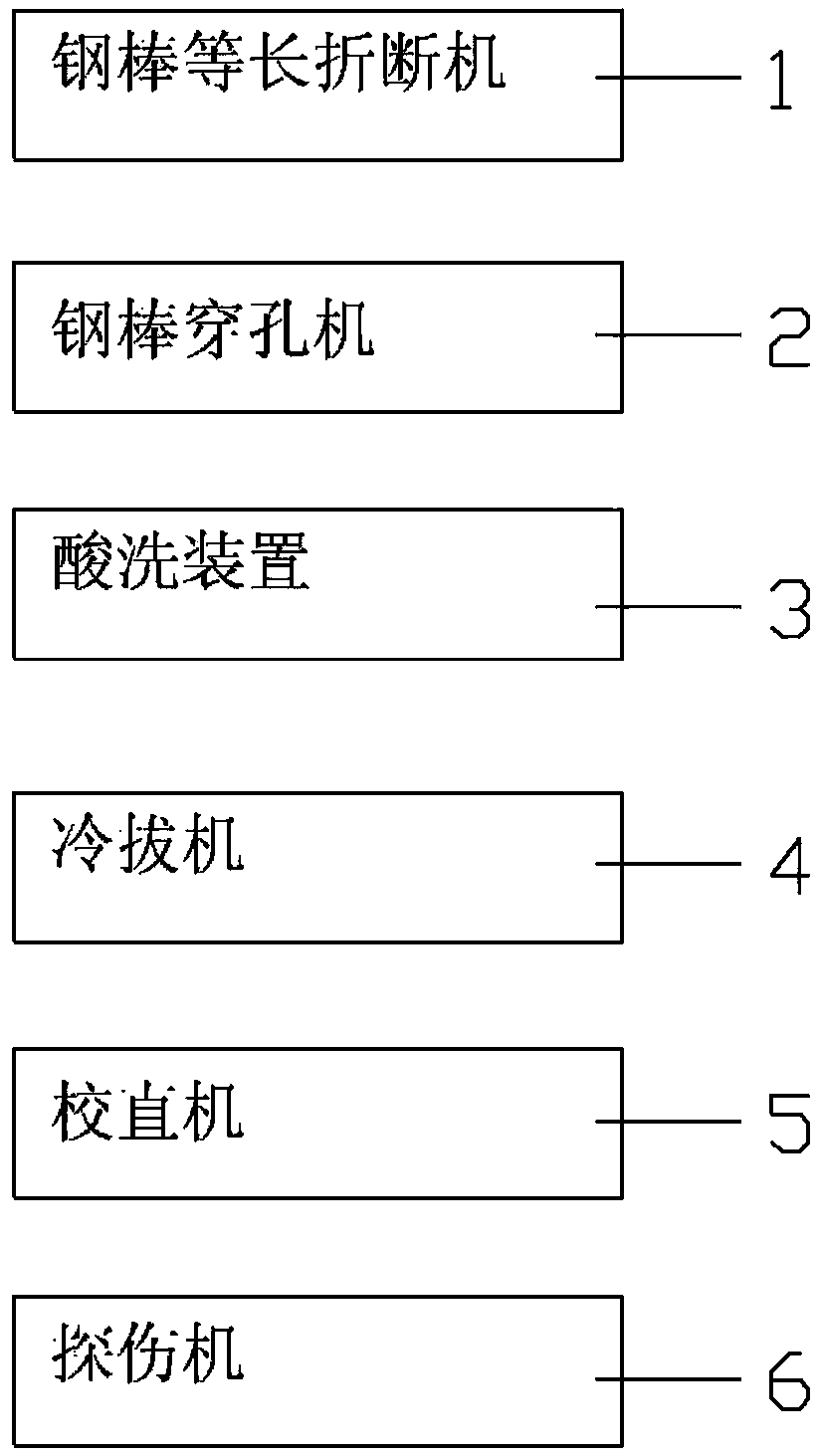

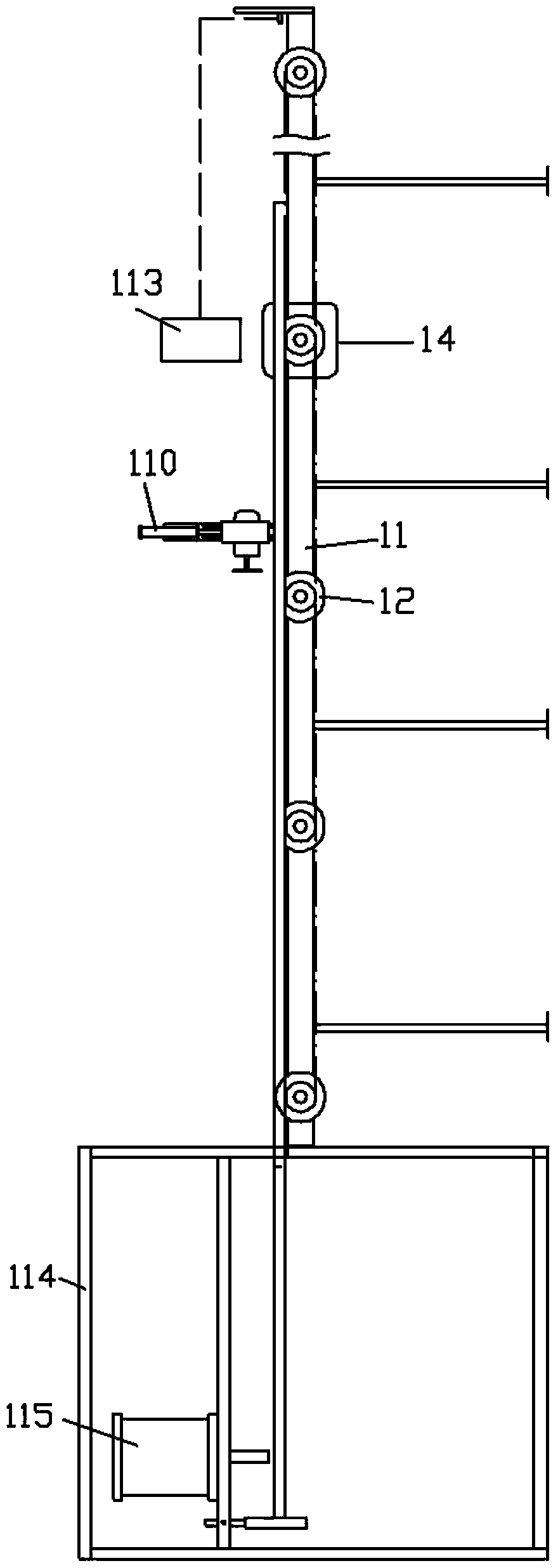

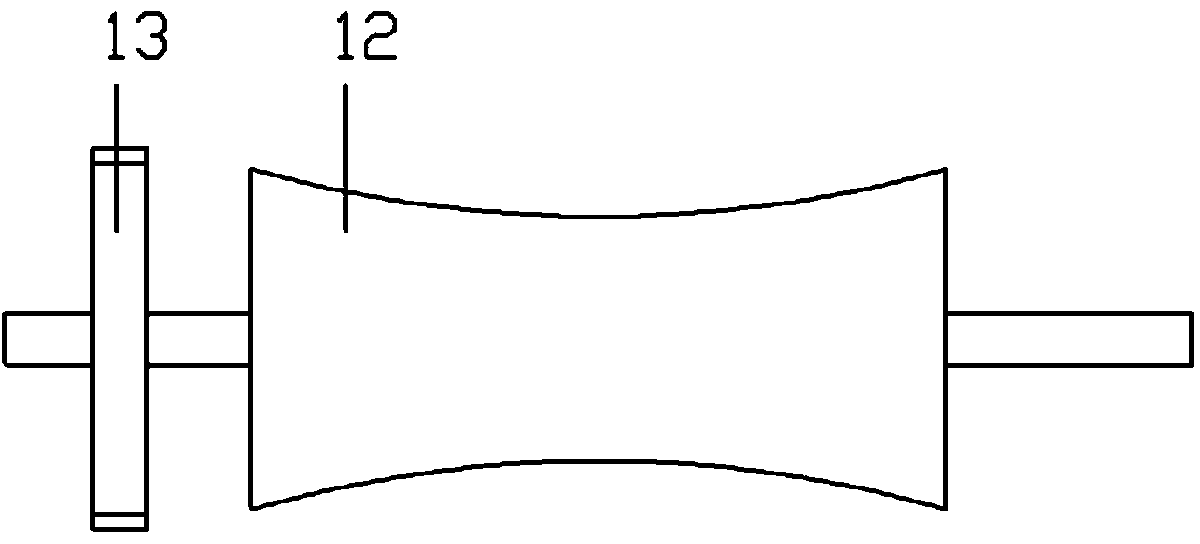

[0031] Example: see Figures 1 to 15 As shown, the automobile airbag steel pipe production line includes steel bar equal-length breaking machine 1, steel bar piercing machine 2, pickling device 3, cold drawing machine 4, straightening machine 5 and flaw detection machine 6, and its steel bar is equal-length breaking machine The structure of the machine 1 is that several breaker conveying rollers 12 are installed on the breaker conveying bracket 11, the breaker conveying rollers 12 are rollers with low middle sides and high sides, and the rotating shaft of each breaker conveying roller 12 is fixed with a broken The machine roller chain 12, the rotating shaft of the breaking machine conveying motor 14 drives the breaking machine roller chain 12 to rotate through the sprocket and the chain, and the steel bar A is placed on the breaking machine conveying roller 12;

[0032] The cutting support 15 is fixed on the conveying bracket 11 of the breaking machine, the sliding table 16 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com