3D printing vehicle-mounted factory

A 3D printing and factory technology, applied in the field of 3D printing equipment, can solve the problems of insufficient product precision, inability to add additives, large optionality, etc., and achieve the effect of easy movement and portability, low cost, and space saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

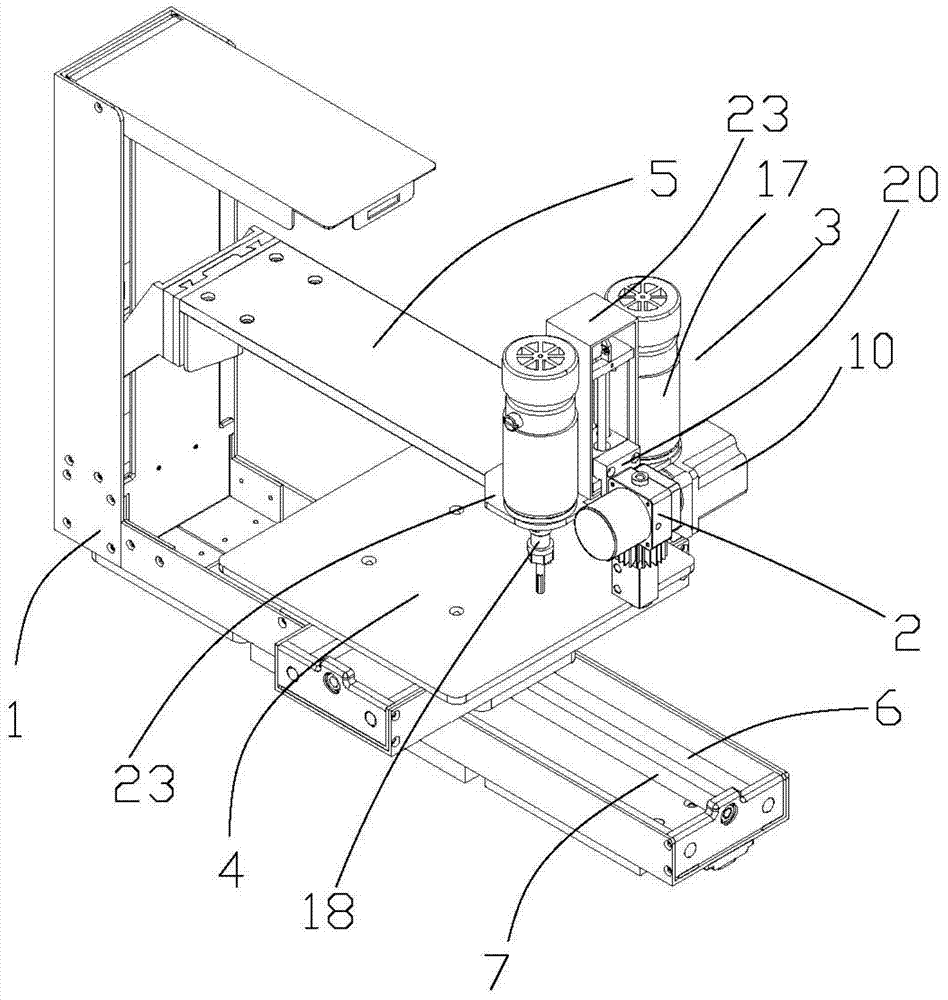

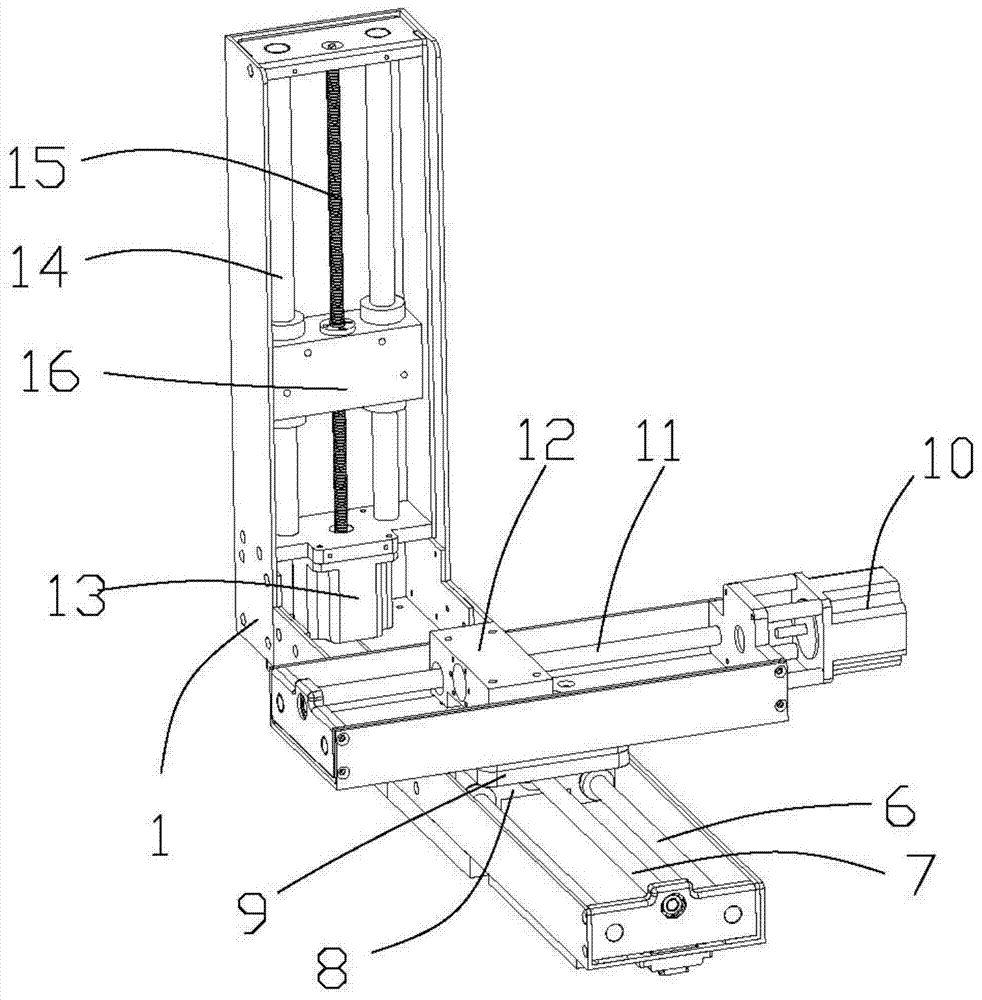

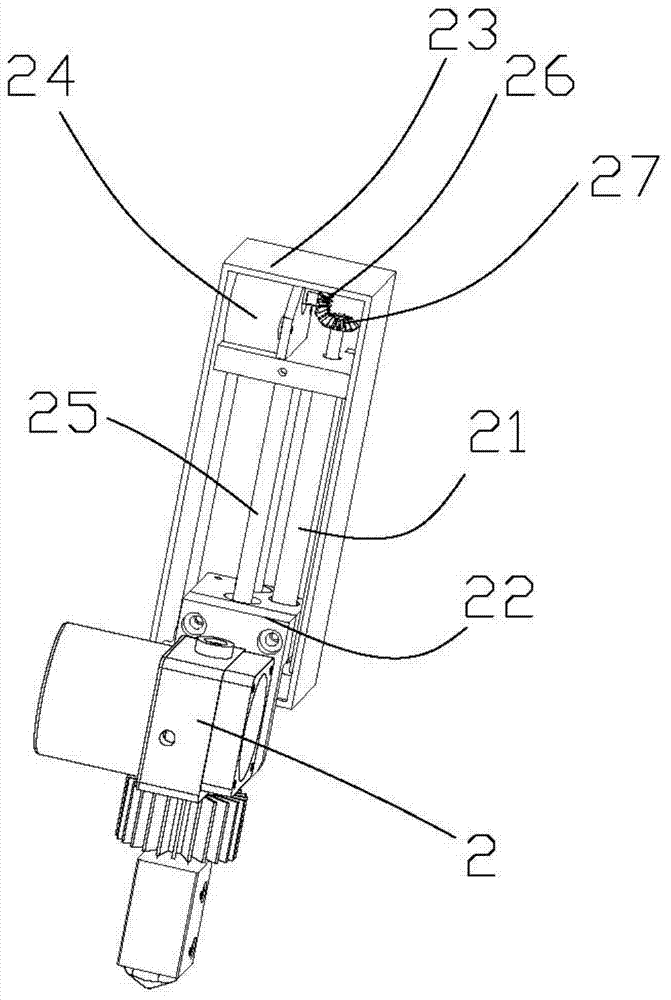

[0024] refer to Figure 1 to Figure 3 , the invention discloses a 3D printing vehicle-mounted factory, which mainly includes a CNC control center (not shown in the figure), a machine base 1, a printing head 2, a processing mechanism 3, a workbench 4, an X-axis moving mechanism, and a Y-axis moving mechanism. Moving mechanism and Z-axis moving mechanism.

[0025] The machine base 1 is composed of two mutually perpendicular square shells. The machine base 1 is an "L"-shaped structure as a whole, and one side of the shell is open. The X-axis moving mechanism is set in the bottom shell, and the Y-axis moving mechanism is set In the vertical casing, the above-mentioned structure makes full use of the internal space of the machine base 1, making the overall equipment more miniaturized.

[0026] The Y-axis moving mechanism is arranged on the X-axis moving mechanism, and the workbench 4 is arranged on the Y-axis moving mechanism, so that the workbench can be realized through the comb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com