A method of making a transparent material for simulating internal crack propagation in rocks

A technology of internal cracks and transparent materials, applied in the field of rock mass failure prediction in geotechnical engineering, can solve the problems of unrealistic cracks, difficulty in prefabricating cracks, failure to observe crack expansion, etc., and achieve the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

[0023] A method for making a transparent material for simulating internal crack extension of rocks according to the present invention comprises the following steps:

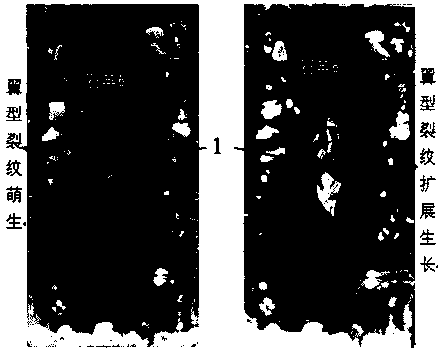

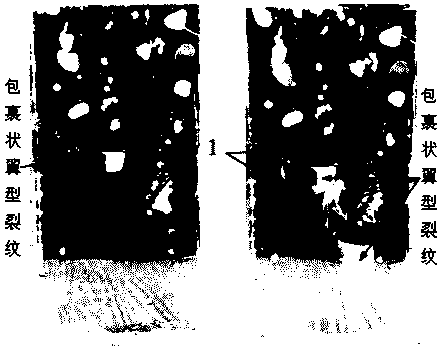

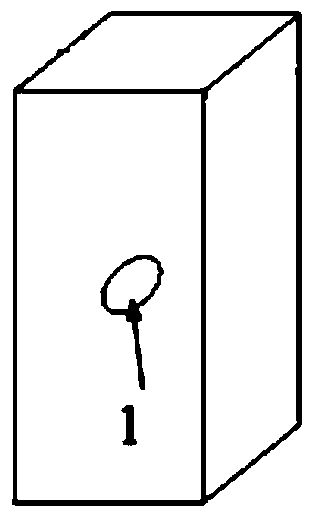

[0024] (1) Mold making: such as Figure 1 to Figure 4 As shown, the mold is made of PMMA material, and the mold can be made into any size according to the needs. For example, it can be a cuboid shape of 50mm*50mm*120mm. The upper mouth of the mold is open and the lower end is closed. A small hole of 2 mm is used to fix the prefabricated crack in the appropriate position inside the mold with a thin cotton thread through the small hole in the subsequent steps, and seal the small hole on the outer layer of the mold;

[0025] (2) Fabrication of prefabricated cracks: Use mica sheet 1 as the prefabricated crack, and cut mica sheet 1 into an ellipse with a major axis of 12 mm, a minor axis of 8 m, and a thickne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com