Production method of high-F soft plush cotton-imitated fiber

A cotton-like fiber, production method technology, applied in textiles and papermaking, spinneret assemblies, single-component polyester rayon, etc., can solve the problem of low fiber evenness, energy consumption, cooling air volume, etc. Large and other problems, to achieve the effect of good water absorption, soft quality and uniform temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

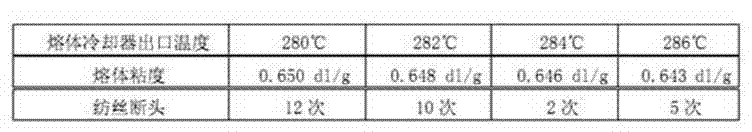

Embodiment 1

[0040] In the production method of the high F soft velvet cotton-like fiber described in this example, the polyester is put into the final polymerization tank and passed through the melt distributor, and then the booster pump is used to transport the melt through the melt cooler and then enters the static mixer Then, after passing through the melt distributing valve, it enters the spinning box, extrudes the melt by a metering pump, spins on the spinning assembly, uses a ring blower to cool and form, and finally goes through oiling, spinning Winding, winding, quality inspection, and packaging are carried out after the tunnel, network device, GR1 godet, and GR2 godet; the viscosity of the melt is 0.646dl / g, and the outlet temperature of the melt cooler is controlled at 284°C .

[0041] In the selection of the spinneret, the analysis and design were carried out from the perspective of improving the dyeing. It is necessary to consider that the number of 192F holes must meet the re...

Embodiment 2

[0055] In the production method of the high F soft velvet cotton-like fiber described in this example, the polyester is put into the final polymerization tank and passed through the melt distributor, and then the booster pump is used to transport the melt through the melt cooler and then enters the static mixer Then, after passing through the melt distributing valve, it enters the spinning box, extrudes the melt by a metering pump, spins on the spinning assembly, uses a ring blower to cool and form, and finally goes through oiling, spinning Winding, winding, quality inspection, and packaging are carried out after the tunnel, network device, GR1 godet, and GR2 godet; the viscosity of the melt is 0.643dl / g, and the outlet temperature of the melt cooler is controlled at 280°C .

[0056] The hole length of the spinneret hole in the spinneret in the spinning box is 0.18mm, and the spinneret hole is circular.

[0057] Low-pressure spinning is adopted, and the post-pump pressure of ...

Embodiment 3

[0066] In the production method of the high F soft velvet cotton-like fiber described in this example, the polyester is put into the final polymerization tank and passed through the melt distributor, and then the booster pump is used to transport the melt through the melt cooler and then enters the static mixer Then, after passing through the melt distributing valve, it enters the spinning box, extrudes the melt by a metering pump, spins on the spinning assembly, uses a ring blower to cool and form, and finally goes through oiling, spinning Winding, winding, quality inspection, and packaging are carried out after the tunnel, network device, GR1 godet, and GR2 godet; the viscosity of the melt is 0.650dl / g, and the outlet temperature of the melt cooler is controlled at 286°C .

[0067] The hole length of the spinneret hole in the spinneret in the spinning box is 0.18mm, and the spinneret hole is circular.

[0068] Low-pressure spinning is adopted, and the post-pump pressure of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hole length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com