Cutter hook combining body of loop cutting machine

A combined body and loop cutting machine technology, which is applied in the direction of double-sided pile fabric cutting and other directions, can solve the problems of high technical difficulty and high equipment, and achieve the effects of improving cutting speed, simple structure and reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific technical solutions of the present invention will be further described below with reference to the accompanying drawings, so that those skilled in the art can further understand the present invention, without limiting their rights.

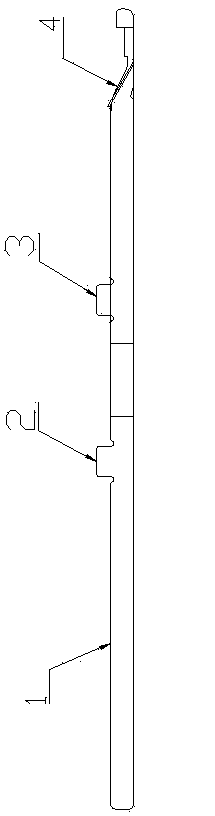

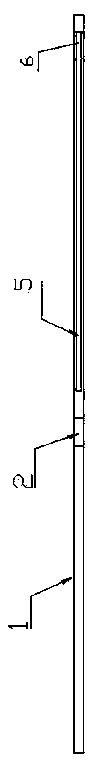

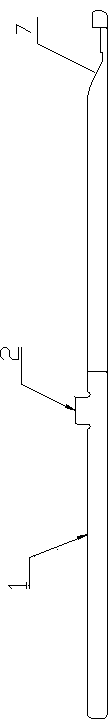

[0019] refer to Figure 1-8 , a knife-hook assembly of a ring cutting machine, comprising a crochet needle 1 and a cutting knife 4, a needle hammer 2 is provided in the middle of the needle body of the crochet needle 1, and a threading hole 6 is provided on the needle head of the crochet needle 1, and a threading hole 6 is provided in the threading hole 6 The needle body between the needle hammer 2 is provided with a sipe 5 parallel to the axis of the crochet needle 1. The sipe 5 communicates with the threading hole 6. The cutting knife 4 is installed in the sipe 5, and the tail of the cutting knife 4 The end is provided with a knife hammer 3 flush with the needle hammer 2, and the front end of the cutter 4 is provided with a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com