Inner inclined support assembled type concrete shear wall prefabricated part

A technology of concrete shear walls and prefabricated components, which is applied in the direction of building components, walls, manufacturing tools, etc., can solve the problems of inconsistent main tension, lack of strength, bearing capacity and earthquake resistance, and cannot limit the development of oblique cracks, etc., to achieve bearing capacity And the stiffness attenuation is slow, the degree of damage is light, and the effect of enhancing the earthquake resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

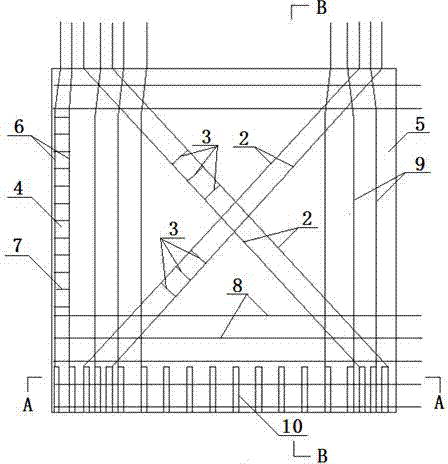

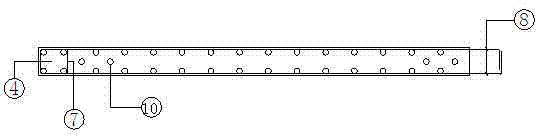

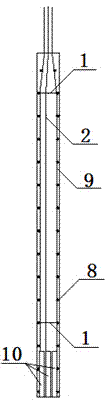

[0010] figure 1 , figure 2 and image 3 A structural reinforcement schematic diagram of a structural unit of the present invention is given. It is composed of constrained edge members 4 and built-in obliquely braced shear wall panels 5. The reinforcement of the regular quadrilateral constrained edge member 4 is four longitudinal steel bars 6, and the quadrilateral constrained edge member stirrups are evenly bound along the longitudinal reinforcement. 7. The reinforcement of the shear wall 5 is to uniformly arrange the transverse distribution bars 8 of the shear wall and the longitudinal distribution bars 9 of the shear wall on both sides along the horizontal and vertical directions, and bind and fix them at the intersection points to form two pieces of steel mesh, and the steel bars Tension bars 1 are used to connect the nets, and steel bars are reserved at the upper ends of the longitudinal steel bars 9 for lap joint anchorage, and the length of the reserved steel bars mu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com