Front driver speed measuring device

A tachometer and precursor technology, which is applied to measurement devices, transmission parts, linear/angular velocity measurement, etc., can solve the problems of high-frequency vibration, affect the laser tracking effect, low measurement accuracy, etc., to compensate for coaxiality errors, avoid Vibration up and down and slippage from the shaft, the effect of high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to further understand the inventive content, features and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0015] Such as figure 1 with 2 as shown,

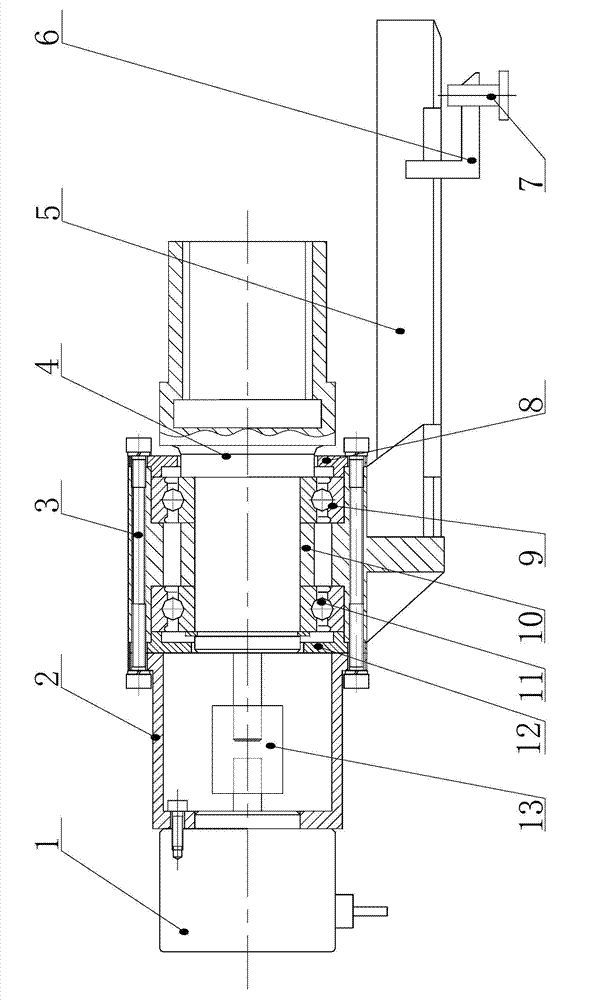

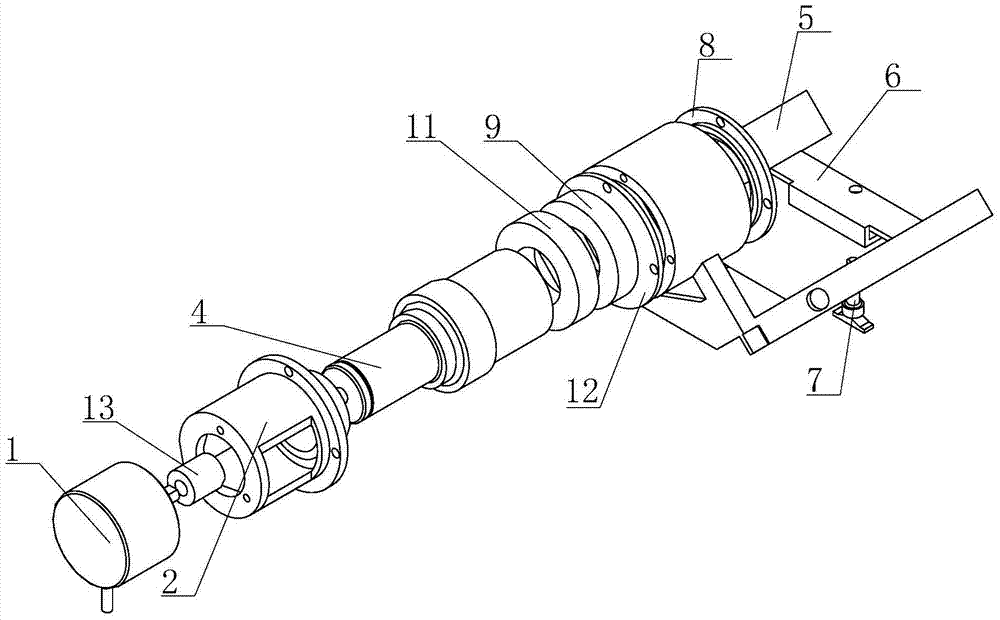

[0016] A front-drive speed measuring device, including a bearing seat 3, in which a spline shaft 4 is installed through a rolling bearing. Specifically, two rolling bearings——bearing A 9 and bearing B—are arranged in the sleeve part of the bearing seat. 11. The two bearings are separated by a shaft sleeve 10. The right side of bearing A is positioned by the end cover A 8 installed on the bearing seat by bolts, and the right side of bearing B is positioned by the end cover installed on the bearing seat by bolts. B12 positioning,

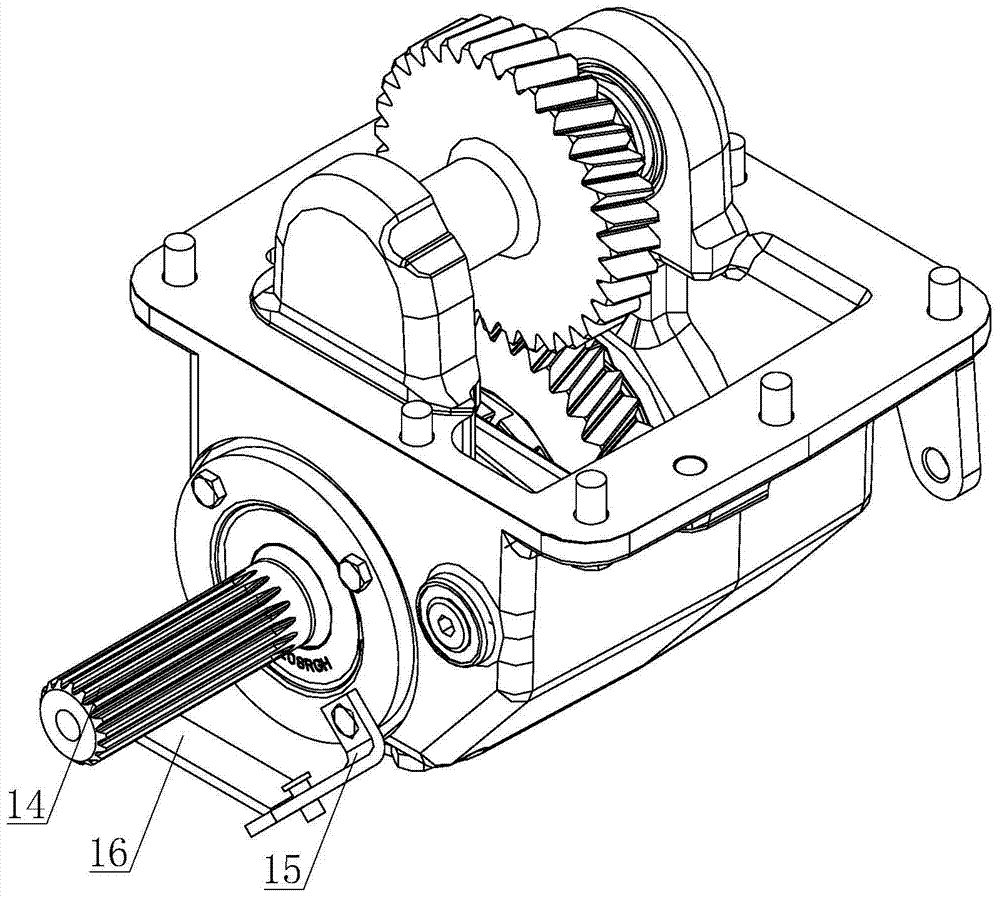

[0017] The front end of the spline shaft has a spline inner hole for spline connection with the front drive output shaft 14, the rear end of the spline shaft is connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com