An anti-overflow device for a drainage box, an anti-overflow drainage box, and an exhaust method for the drainage box

A drainage tank and anti-overflow technology, applied in chemical instruments and methods, separation methods, liquid degassing, etc., can solve problems affecting the operation of the drainage system, overflow of the water tank, and speed of movement, etc., to achieve great practical value and promotion value , Guaranteed stable operation and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

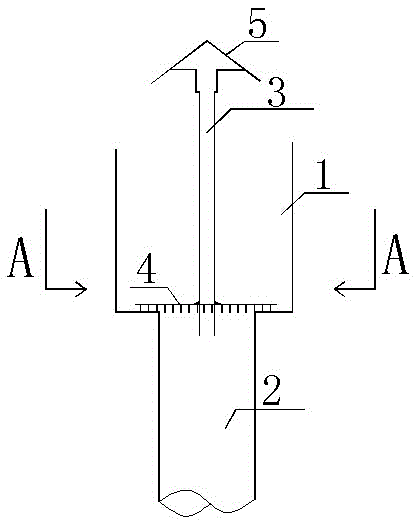

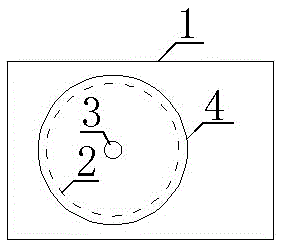

[0017] Referring to the accompanying drawings, an anti-overflow device for a drainage tank includes an exhaust pipe, a grate water cover and an exhaust cap. The grate water cover includes a round steel plate and a round steel support, and the round steel plate passes through the round steel support. It is fixedly installed on the top of the drainage main pipe. The diameter of the circular steel plate is larger than that of the corresponding drainage main pipe. The centerline of the circular steel plate of the grate water cover coincides with the center line of the drainage main pipe. The circular steel plate of the grate water cover has a hole. The point is located at the center point of the circular steel plate of the grate water cover, and the diameter of the opening is a quarter of the diameter of the main drainage pipe. Inside, the top of the exhaust pipe is higher than the height of the water tank. The exhaust cap is set on the top of the exhaust pipe and supported by four...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com