Refrigerant automatic recycling air conditioner system and control method thereof

An air-conditioning system and automatic recovery technology, applied in the direction of refrigerators, refrigerants, refrigeration components, etc., can solve the problems of affecting the use effect of air-conditioning, causing great social harm, and destroying the ozone layer, achieving simple structure, low cost, and avoiding experience differences. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

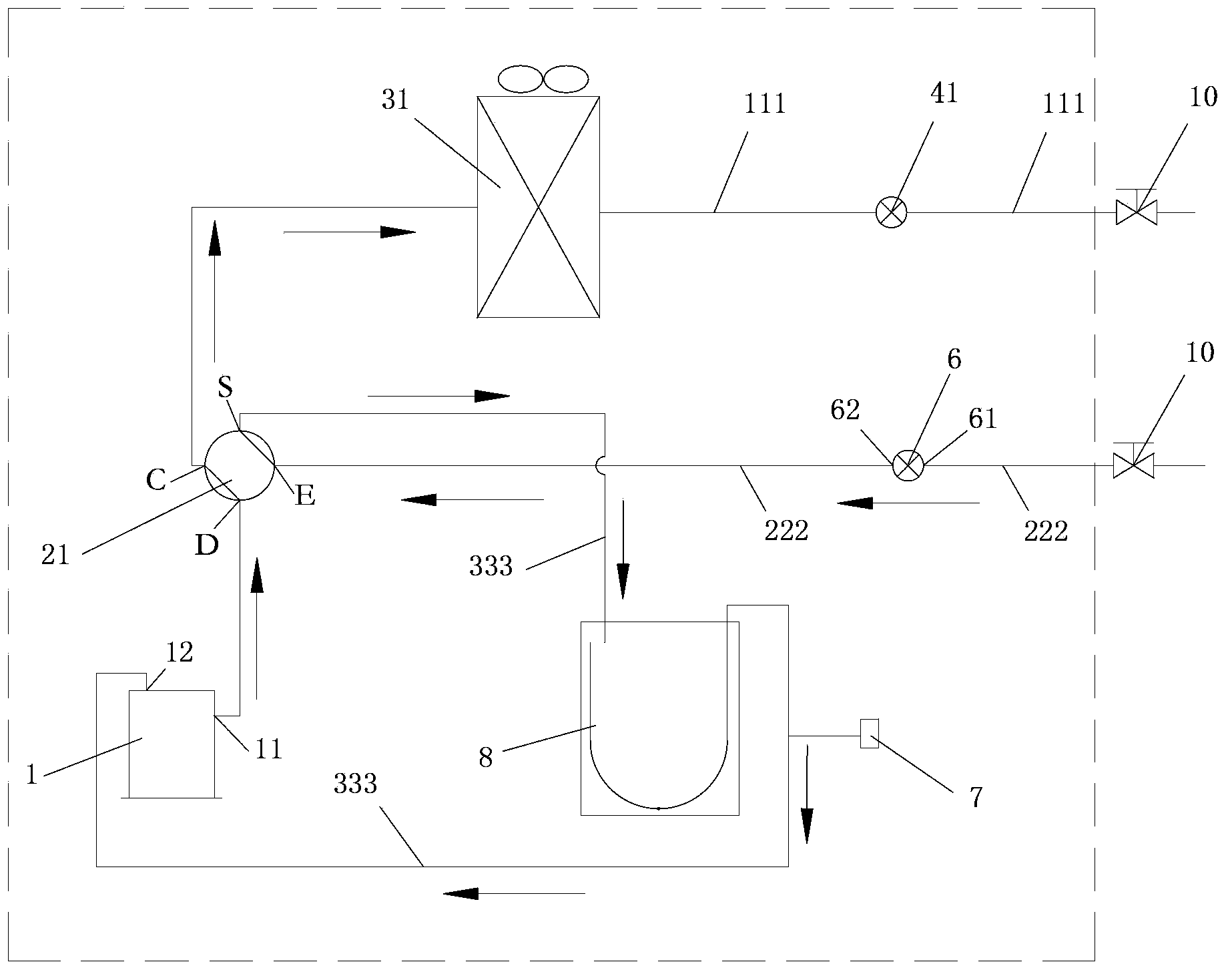

Embodiment 1

[0033] see figure 1 , is the air-conditioning system with automatic refrigerant recovery provided in Embodiment 1 of the present invention. The refrigerant automatic recovery air conditioning system mainly consists of a compressor 1, a four-way valve 21, an outdoor heat exchanger 31, an indoor heat exchanger (not shown in the figure) and a throttling component 41 connected through refrigerant pipelines. The refrigerant circulation circuit and the controller (not shown in the figure) that control the operation of the air conditioning system; specifically, the D pipe port of the four-way valve 21 is connected to the exhaust port 11 of the compressor 1, and the C pipe port exchanges heat with the outdoor The device 31 is connected to the S nozzle and the low-pressure air return pipe 333 connected to the suction port 12 of the compressor 1, and the throttling part 41 is arranged on the high-pressure liquid pipeline 111 between the outdoor heat exchanger and the indoor heat exchang...

Embodiment 2

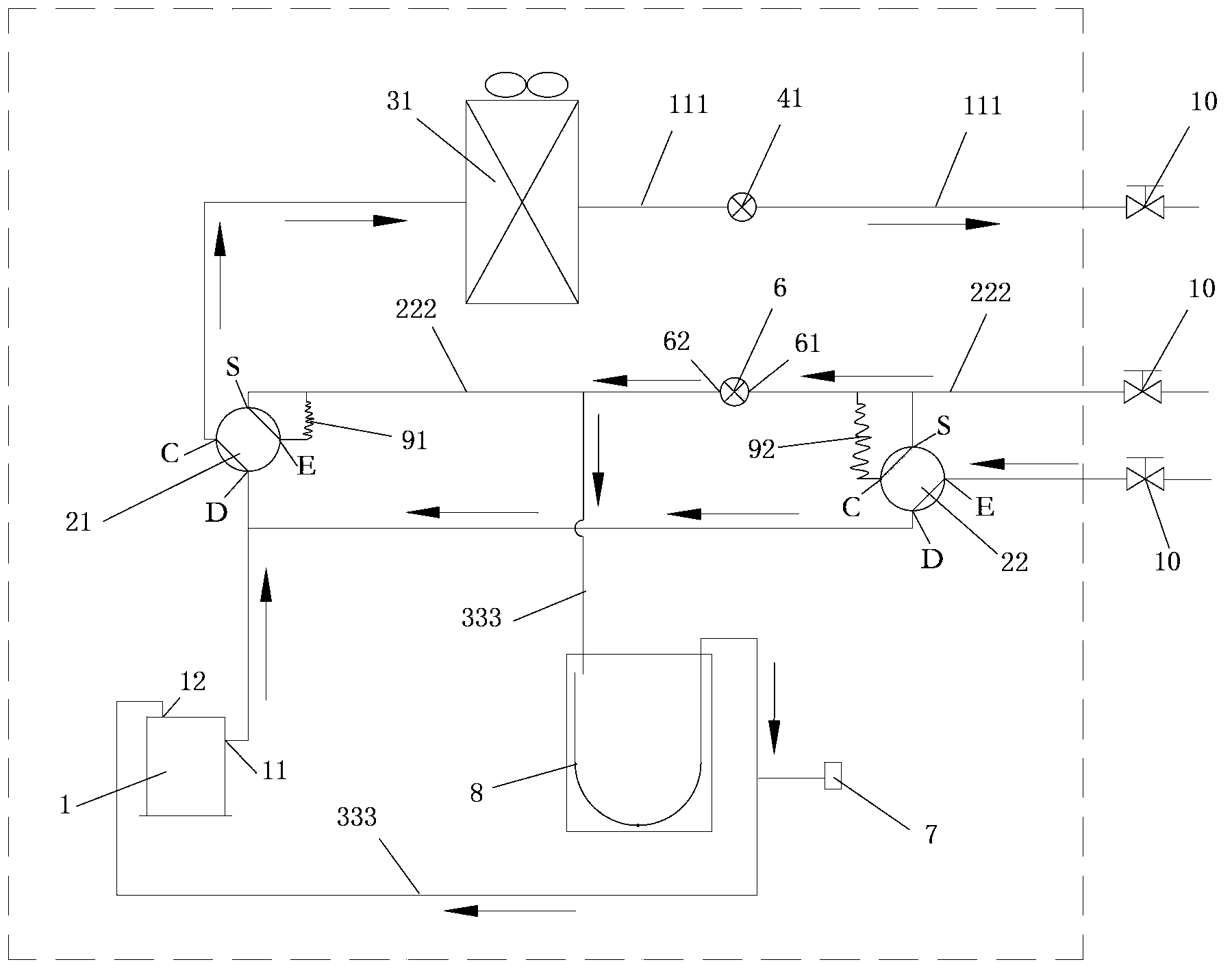

[0047] see figure 2 , the structure of the refrigerant automatic recovery air-conditioning system in this embodiment is different from that in Embodiment 1, mainly changing from two pipes to three pipes, so that the number of indoor heat exchangers can be increased, which includes a compressor 1, an outdoor Heat exchanger 31, a throttling component 41, the first four-way valve 21 and the second four-way valve 22; specifically, the C nozzle of the first four-way valve 21 is connected to the outdoor heat exchanger 31, The S pipe mouth is connected with the low-pressure gas line 222 connected to the second port 62 of the control valve 6, the E pipe mouth is connected with one end of the first capillary 91, and the other end of the first capillary 91 is connected with the second port of the control valve 6. The low-pressure air pipe line 222 of 62 is connected, and the D nozzle is connected with the exhaust port 11 of the compressor 1;

[0048] And the C nozzle of the second fou...

Embodiment 3

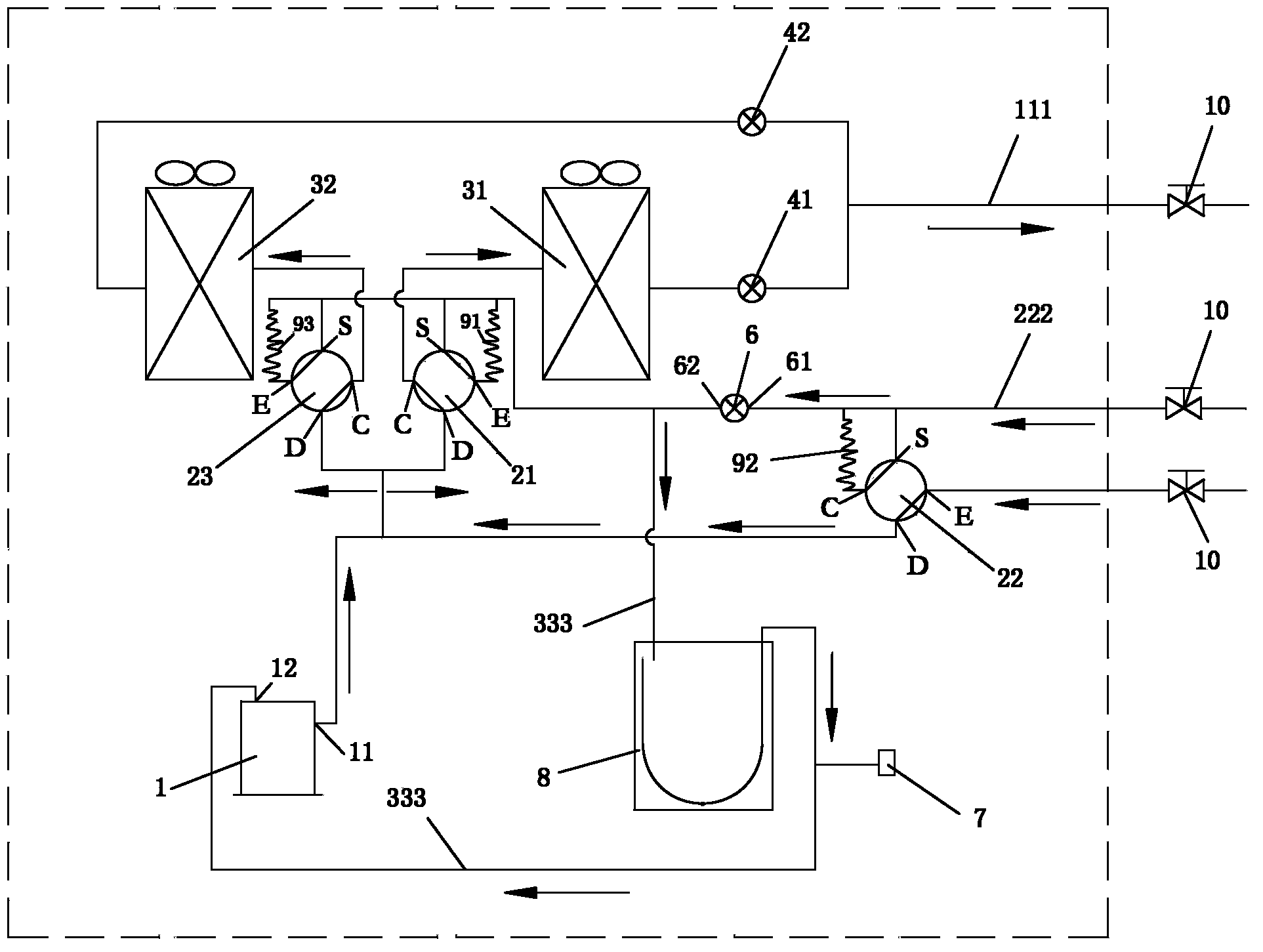

[0055] see figure 2 and image 3 In this embodiment, an outdoor heat exchanger is mainly added on the basis of Embodiment 2. Specifically, a third four-way valve 23, a second throttling member 42, and a third Two outdoor heat exchangers 32, the C nozzle of the third four-way valve 23 is connected to the second outdoor heat exchanger 32, and the S nozzle is connected to the low-pressure air pipe pipeline 222 connected to the second port 62 of the control valve 6 Connection, the E nozzle is connected to one end of the third capillary 93, and the other end of the third capillary 93 is connected to the low-pressure gas line 222 connected to the second port 62 of the control valve 6, and the D nozzle is connected to the exhaust gas of the compressor 1. port 11; and the second throttling part 42 is set on the pipeline between the second outdoor heat exchanger 32 and the indoor heat exchanger, that is, the refrigerant coming out of the outdoor heat exchanger 31 is throttled by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com