Device for measuring combined action of washout and high-temperature corrosion of oil well tubular column

A high-temperature corrosion and co-action technology, applied in the direction of measuring devices, weather resistance/light resistance/corrosion resistance, testing wear resistance, etc., to achieve the effect of maintaining angles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

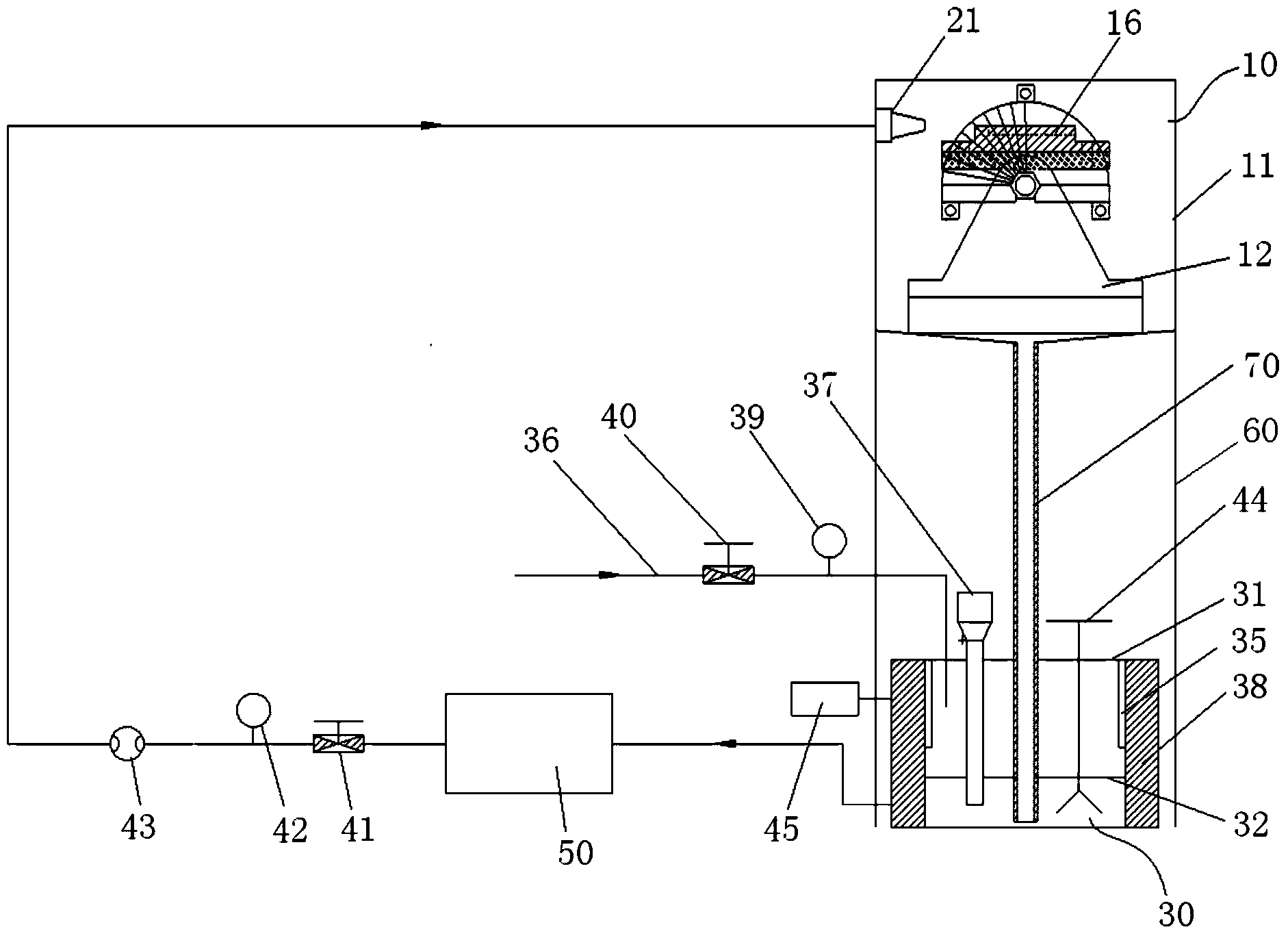

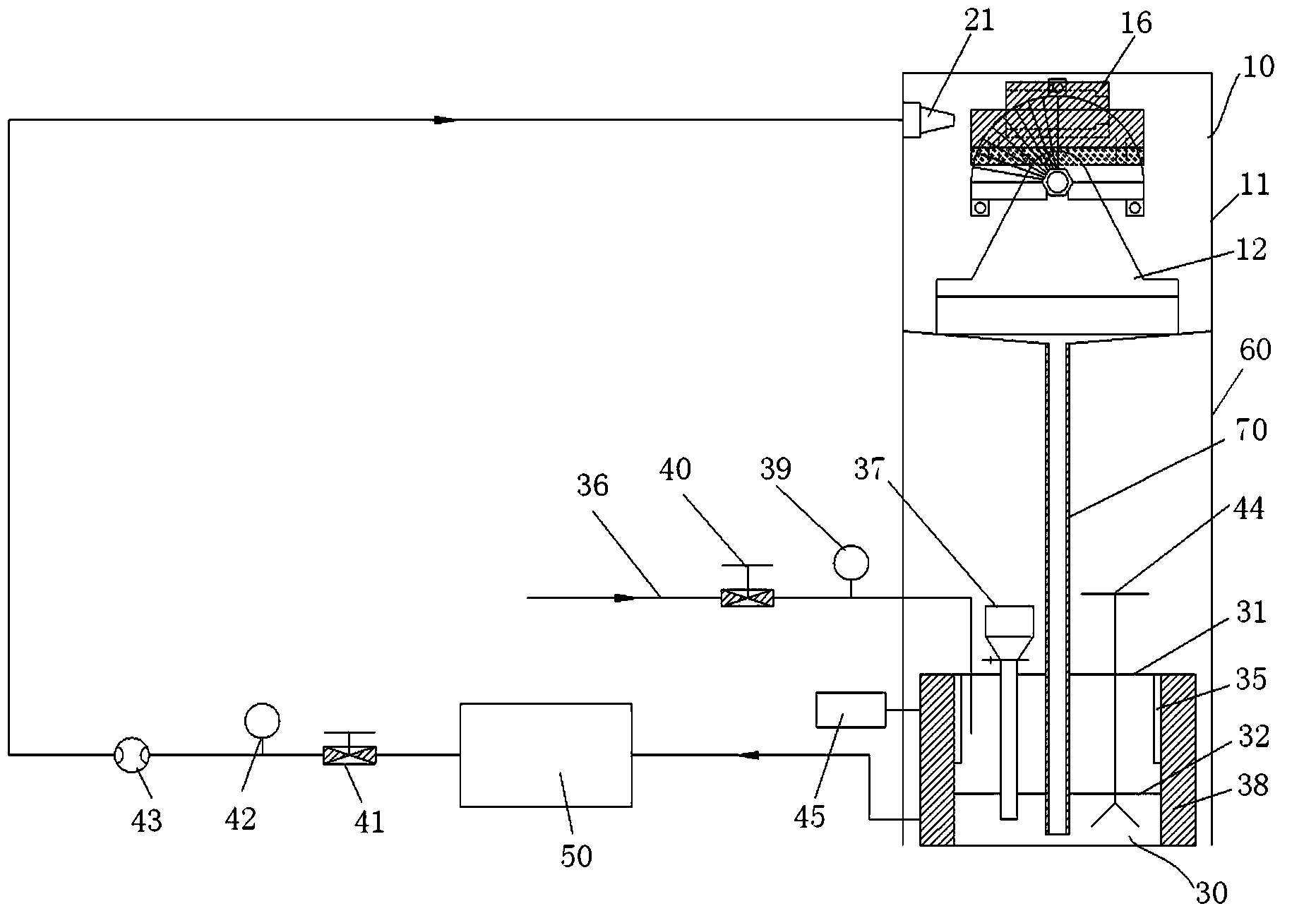

[0025] Such as figure 1 , figure 2 As shown, the present invention includes a simulated erosion tank 10 , a simulated corrosion tank 30 and a constant flow pump 50 .

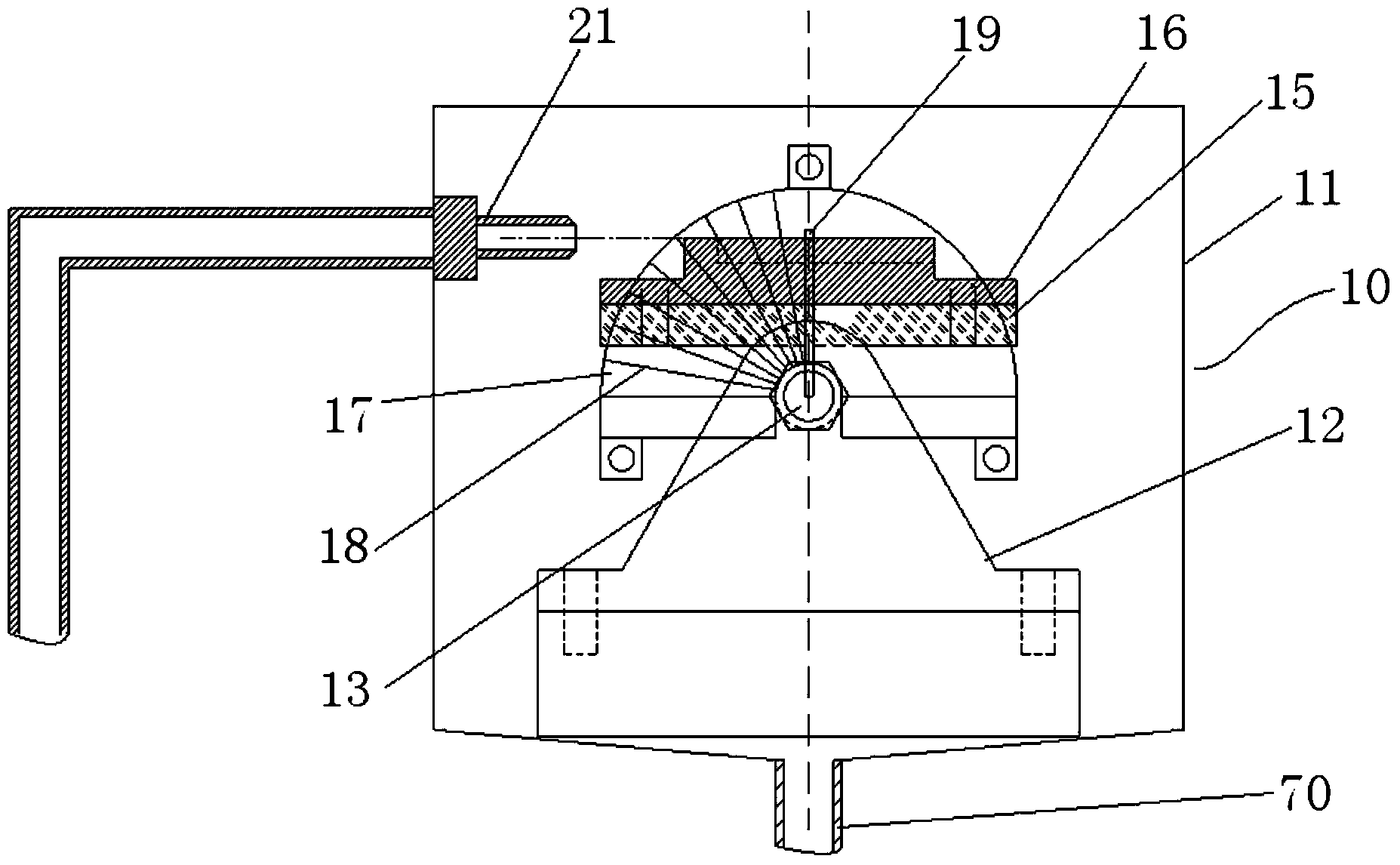

[0026] Such as Figure 3-9 As shown, the simulated erosion box 10 of the present invention includes a box body 11, the box body 11 is supported above the simulated corrosion box 30 by a bracket 60, a support 12 is fixed in the box body 11, and the support 12 is rotatably supported A rotating shaft 13 , one end of the rotating shaft 13 passes through the side wall of the case body 11 and extends to the outside of the case body 11 . A roller 14 is tightly sleeved on the rotating shaft 13 inside the box body 1 , a bearing platform 15 is tightly connected to the top of the roller 14 , and a hanging piece groove 16 is tightly connected to the top of the bearing platform 15 . An angle di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com