Sandstone aggregate production and detection device

A technology for production inspection and aggregates, applied in measuring devices, material weighing, analyzing materials, etc., which can solve problems such as long downtime, low inspection efficiency, and system production impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

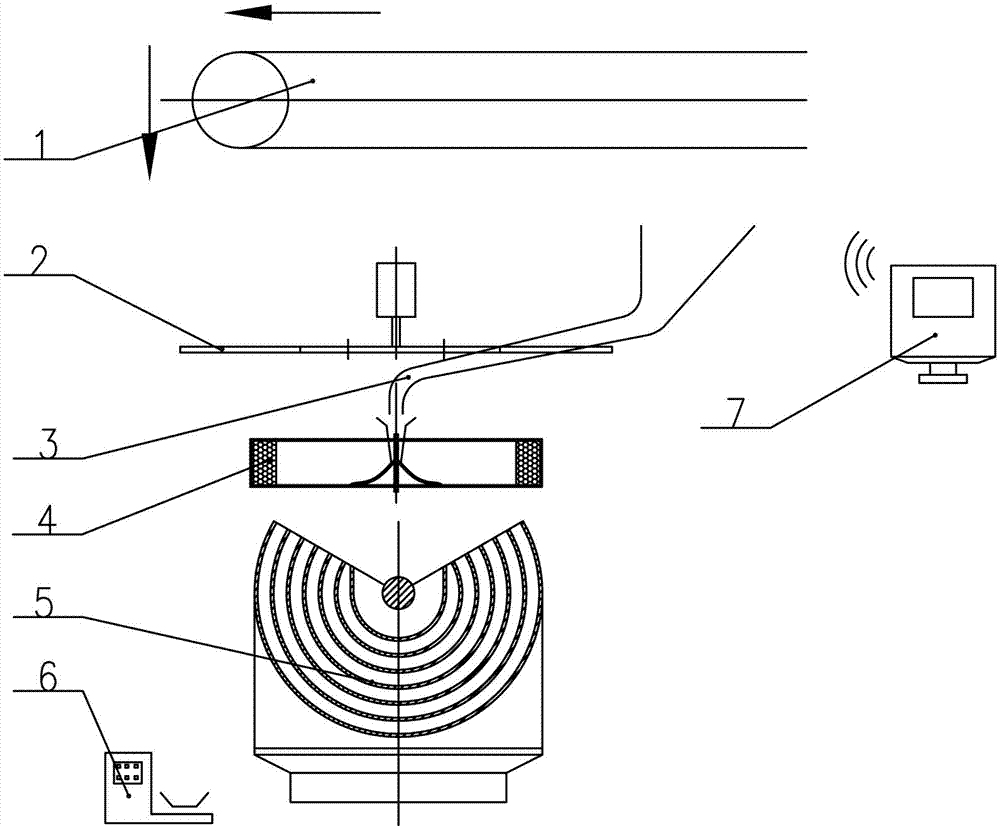

[0015] see Figure 1-3 , On-line gravel aggregate detection device system includes feeding belt 1, feeding turntable 2, feeding hopper 3, dryer 4, screening device 5, weighing device 6, controller 7.

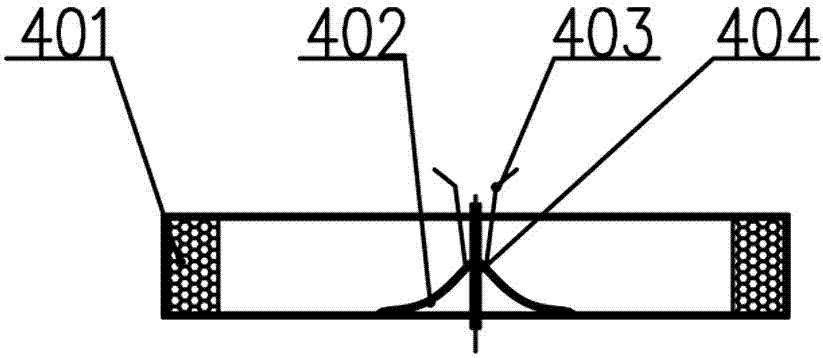

[0016] The dryer described in the present invention includes a drying main chamber 401 , dispersing blades 402 , a feeder 403 , and a rotary drive 404 .

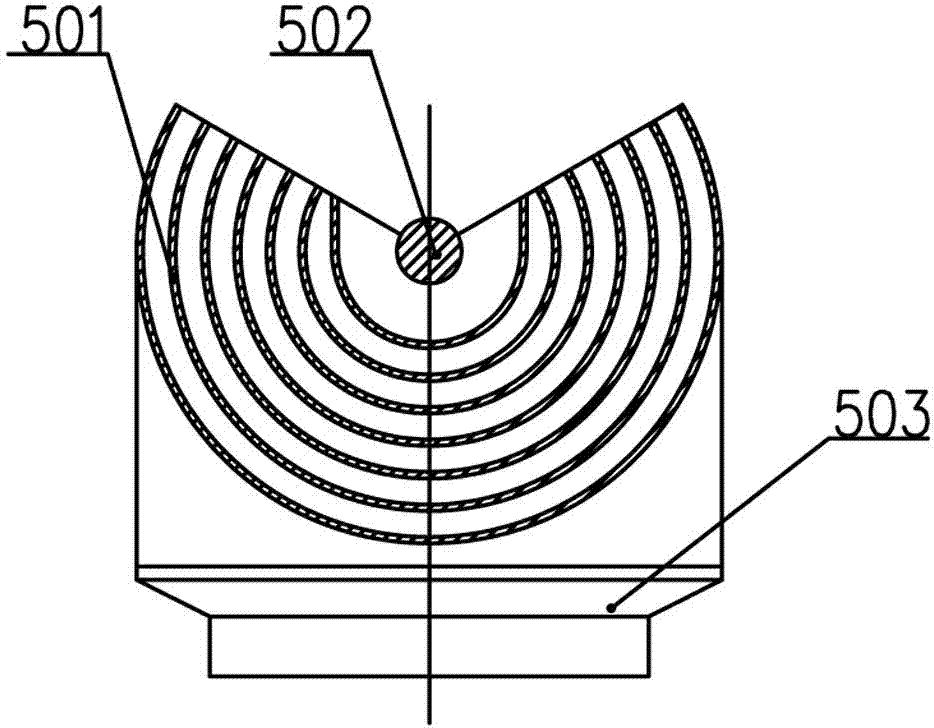

[0017] The screening device of the present invention includes a seven-layer screen 501 , a rotary drive 502 and a screening box 503 .

[0018] The specific working principle of the sand and gravel aggregate on-line detection device system is as follows: when there is no need to take materials, the overall layout is as follows: figure 1 As shown, the turntable is in the position shown in the figure, and the feeding belt 1 normally transports concrete materials. Just below the discharge port of the mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com