Forged integrated strain clamp applied to aluminum alloy stranded conductor

A tension clamp, aluminum alloy technology, applied in the direction of adjusting/maintaining mechanical tension, etc., can solve the problem of increasing the amount of wires and busbars used, the structure size of the tower and the width of the line corridor, increasing the number of split wires, and increasing project investment, etc. problems, to ensure the anti-fatigue performance and electrical performance, improve the control ability, and ensure the effect of normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

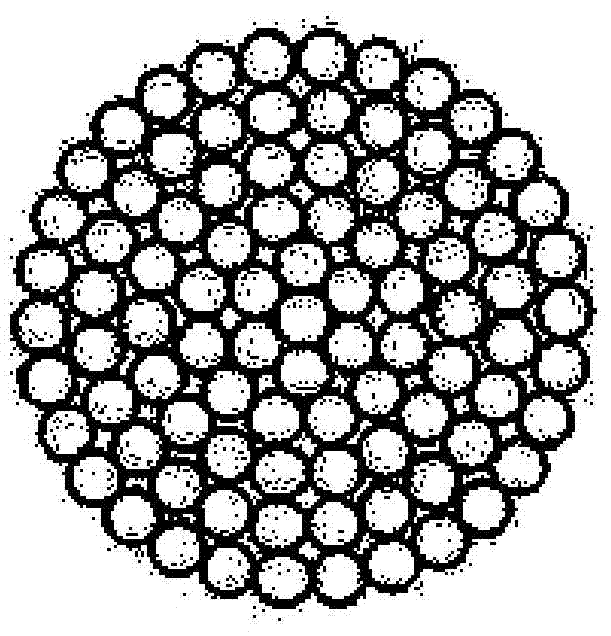

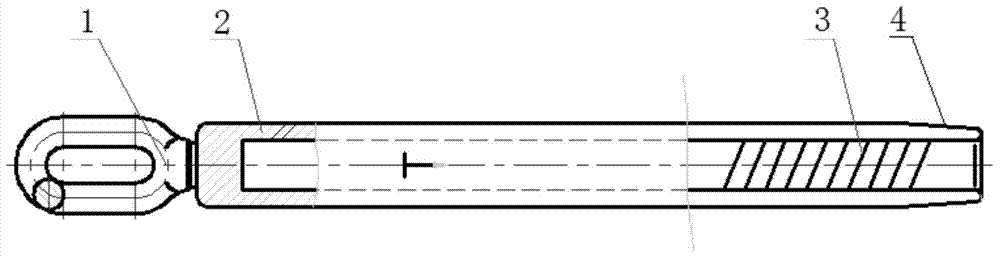

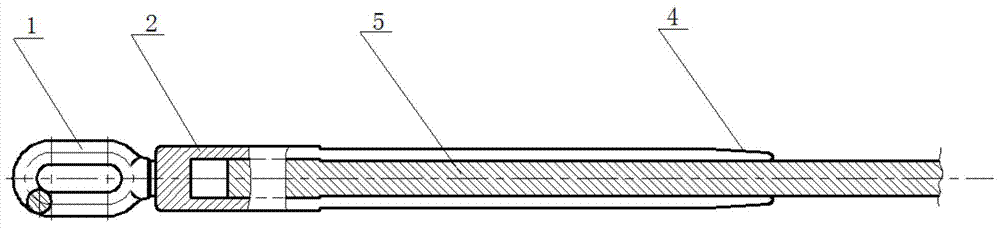

[0043] The strain clamp is made of forged aluminum alloy, and the inner wall at the nozzle of the connecting pipe 2 is provided with a single helical fixing piece 3 with a tapered cross-section along its axis, and the apex angle of the tapered cross-section is 30° , a puller 4 is set outside the nozzle of the connecting pipe 2. Put the ring of the diversion plate 6 on the connecting pipe 2 and weld it together, insert the aluminum alloy stranded conductor 5 into the connecting pipe 2 and press it into one body through hydraulic pressure, the top angle of the fixing part 3 and the aluminum alloy stranded wire The wire 5 is tightly occluded, so that the cavity after the tension clamp and the wire are crimped is fully sealed, and finally the double connecting plate of the drainage clamp 7 after the crimping of the drainage line 9 is inserted into the groove of the drainage plate 6 and fastened with bolts 8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com