Magnetic Sensing Loop for Rotor Position Sensing System of Rectifier Motor

A technology of rectifying motors and sensing systems, which is applied in the direction of using electric/magnetic devices to transfer sensing components, converting sensor outputs, measuring devices, etc., which can solve the problem of inability to ensure the slope and the inability to accurately determine the switch-type Hall sensor Switching points, limited sensor signal resolution, etc., to achieve an improved evaluation of the output signal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

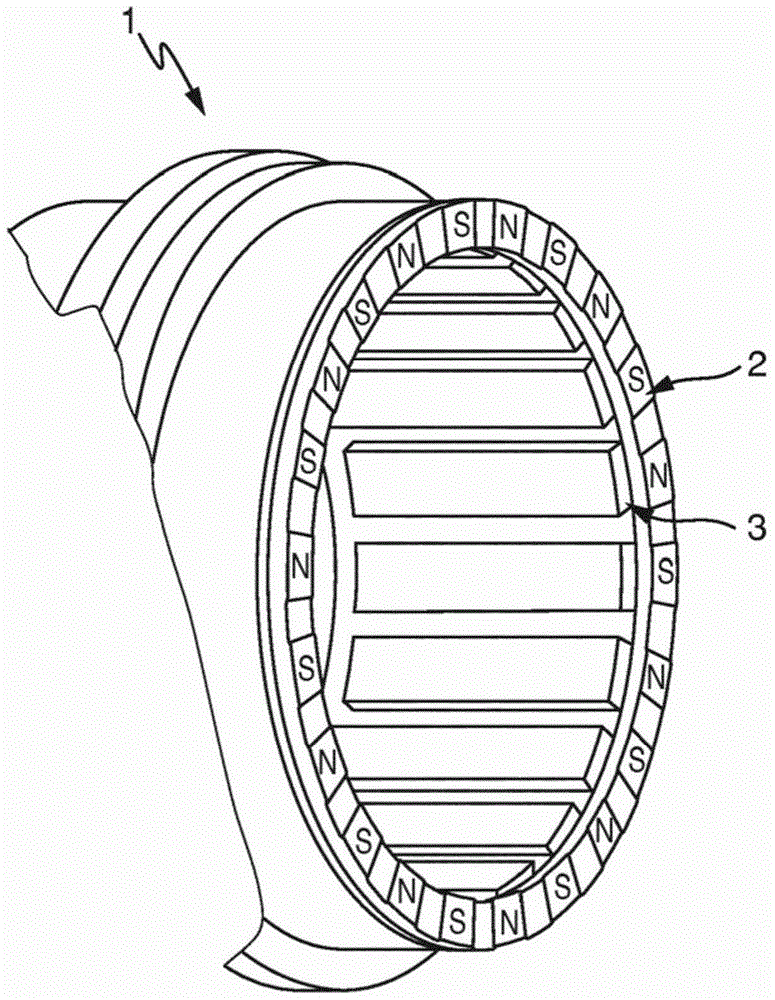

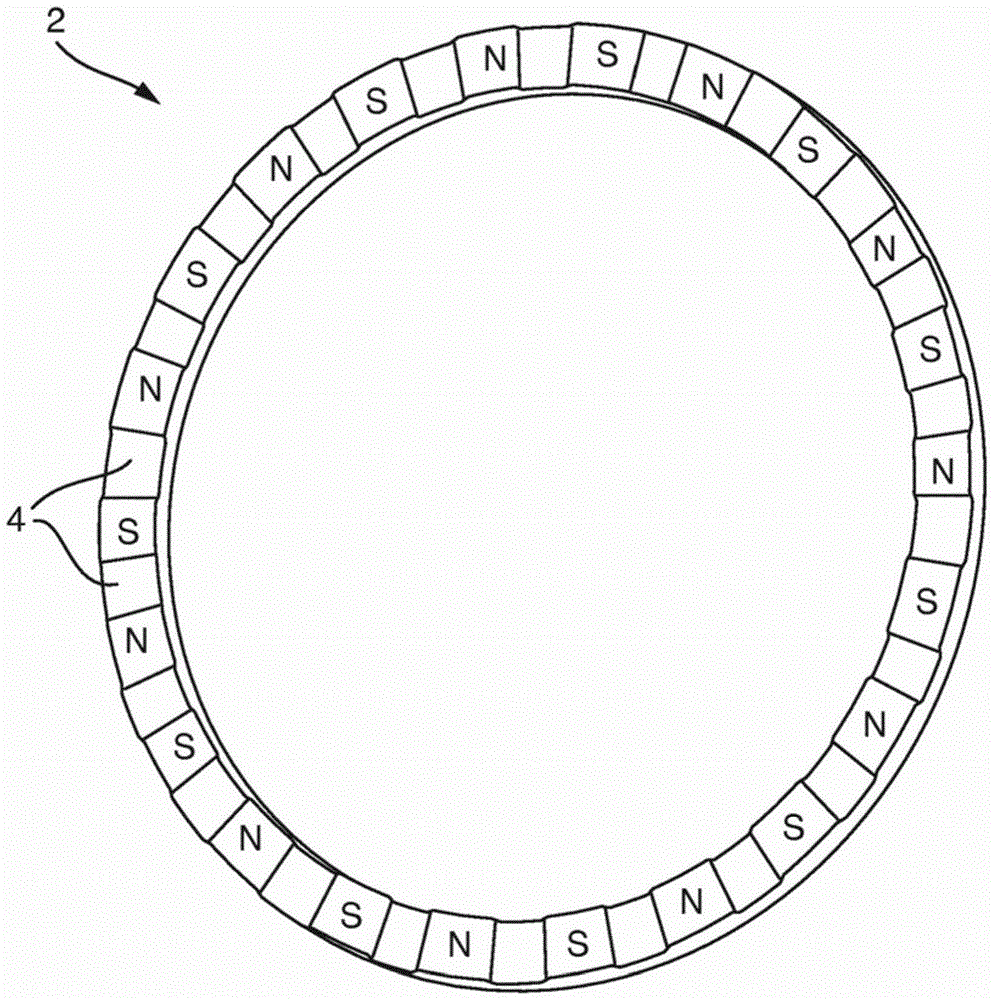

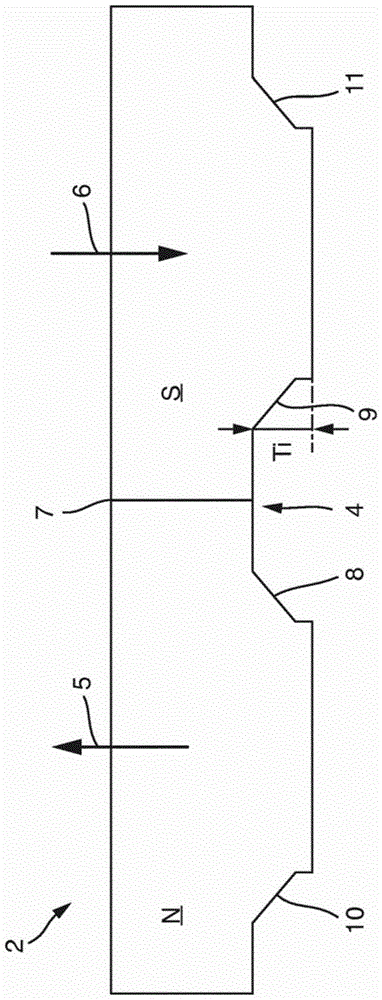

[0027] exist figure 1 The rotor 1 is shown in , which is designed as a hollow shaft. The rotor 1 of the commutated motor (not further shown) has, on the front side facing the sensor system arranged on the stator, a magnetic sensor ring 2 designed as a hollow cylinder with a predetermined number of magnetic poles N , S, the magnetic poles are arranged in an alternating manner. The magnetic poles N and S of the magnetic sensing ring 2 are arranged radially relative to the axis of the rotor 1 . A rotor magnet 3 is fastened within a rotor 1 designed as a hollow shaft, wherein the rotor magnet 3 has the same number of pole pairs N, S as the magnetic sensor ring 2 . The pole pair N, S is here formed by two magnetic poles N, S whose magnetization directions run in opposite directions. The number of rotor magnets 3 is preset by the rectifier motor, thereby also determining the number of magnetic poles N, S on the magnetic sensing ring 2 . Furthermore, a sensor system is to be unde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com