Method for controlling the torque of an asynchronous machine

A technology for asynchronous motors and torque, applied in the control of generators, motor control, motor generator control, etc., can solve problems such as difficult identification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

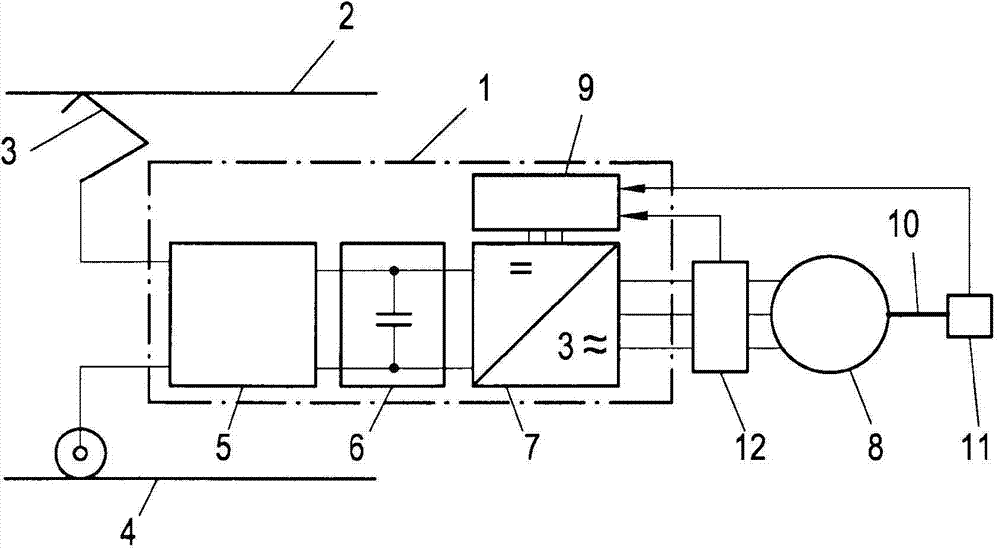

[0017] figure 1 An example of a traction drive of a rail vehicle is shown. The AC asynchronous electric machine 8 of the rail vehicle is controlled via the traction rectifier 1 with a voltage intermediate circuit inverter. Here, the voltage intermediate circuit 6 of the traction rectifier 1 is brought via the input circuit 5 to the voltage tapped off by the collector / brush 1 between the upper line 2 and the rail 4 . If necessary, the input circuit 5 converts the input voltage into a suitable DC voltage, which is fed to the inverter 7 on the voltage intermediate circuit 6 . The object here is to control the inverter 7 of the traction rectifier 1 with the regulating device 9 in such a way that an alternating voltage with variable amplitude and frequency is generated at the terminals of the asynchronous machine 8 in such a way that the asynchronous machine 8 The desired torque is generated on its shaft 10 both stably and dynamically. Here, under normal circumstances, the limi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com