Procede de fabrication d'une pedale creuse bi-matiere et pedale correspondante

A pedal and hollow technology, applied in the direction of control components, mechanical control devices, control/regulation systems, etc., can solve the problems of complicated manufacturing methods, expensive, and complicated pedal structures, and achieve simple and fast manufacturing, light weight, and saving raw materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

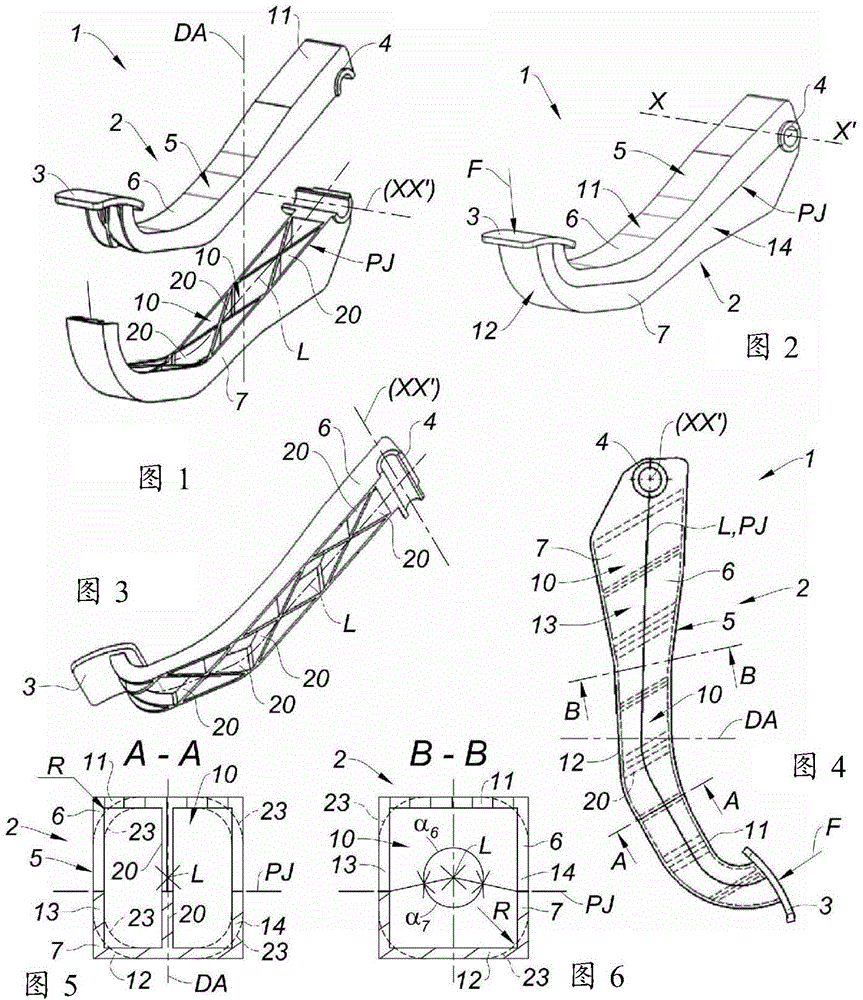

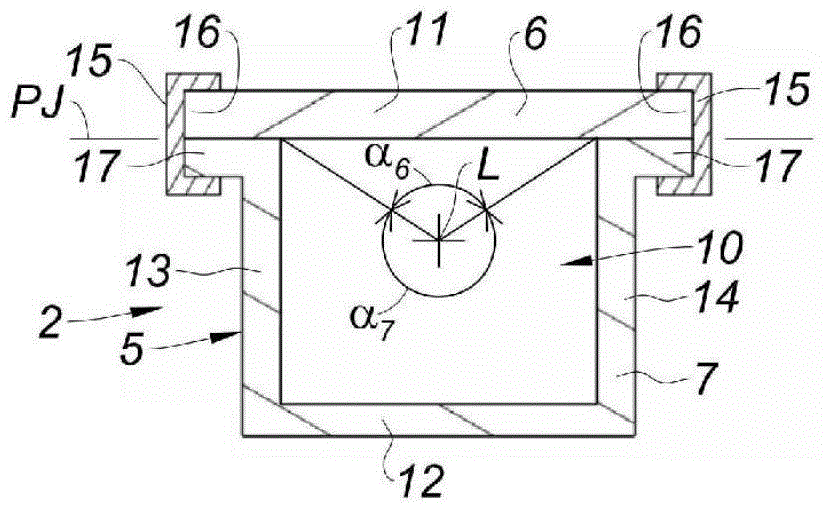

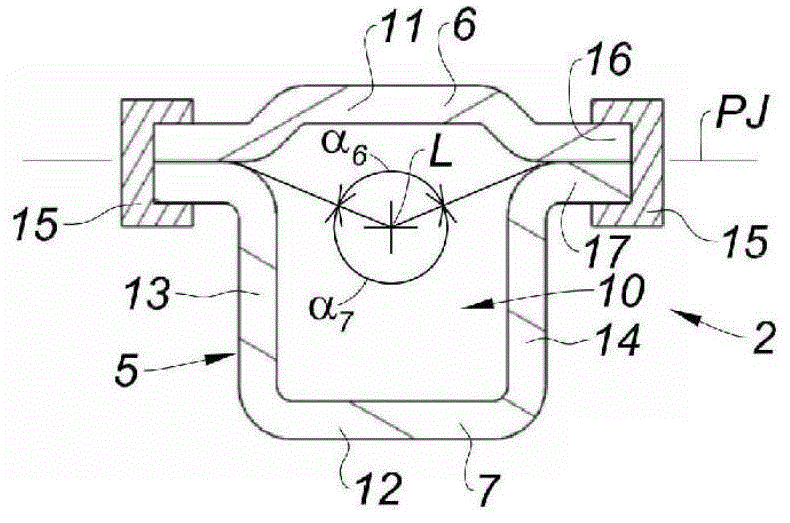

[0037] The invention relates to a pedal 1 comprising a lever 2 extending along a longitudinal direction L from a pad 3 for receiving a control force F to a hinge member 4 for allowing said pedal 1 to oscillate about an oscillating axis (XX').

[0038] The articulation member 4 consists, for example, of a cylinder, preferably pivotally connected with a journal bearing type, articulated at the oscillating axis XX' of the corresponding pedal assembly (not shown).

[0039] Said hinge member 4 is preferably connected to the first end of said lever 2, or is even integrally formed with said lever.

[0040] The pad 3 is preferably arranged substantially at the other end of the lever 2, eg the upper part of the lever.

[0041] Said pad 3 may consist of a plate, preferably curved, attached to or integral with the lever 2 and may be fitted with ridges and / or elastic coating type anti-slip means.

[0042] Usually for a simple and convenient conventional description, according to the long...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com