Straight-core force rib type mesh belt

A straight-heart force, mesh belt technology, applied in transportation, packaging, conveyors, etc., can solve the problems of reduced transportation efficiency, easy leakage of materials, large screw pitch, etc., to improve transportation efficiency, avoid wasting materials, and have a simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

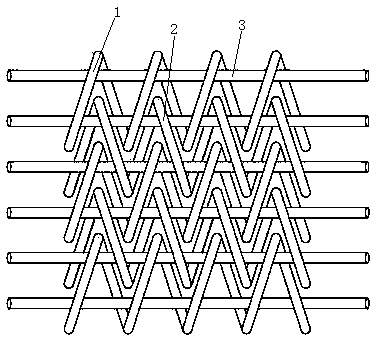

[0010] A kind of straight rib type mesh belt, including several rows of staggered left helical mesh strips 1 and right helical mesh strips 2, a series of strips pass between adjacent left helical mesh strips 1 and right helical mesh strips 2 3 connections, the trough of the left helical mesh strip 1 is in close contact with the adjacent crest of the right helical mesh strip 2, and the crest of the left helical mesh strip 1 is in close contact with the adjacent trough of the right helical mesh strip 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com