Humidification treatment method and device for unwinding polyacrylonitrile precursors for carbon fibers during carbonization

A technology of polyacrylonitrile and processing method, which is applied in the direction of thin material processing, transportation and packaging, transportation of filamentous materials, etc., can solve the problems of increasing fiber bundles, large static electricity of raw filaments, poor bundles, etc., and improve the reaction state. , the effect of improving the yield of qualified products and improving the quality stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

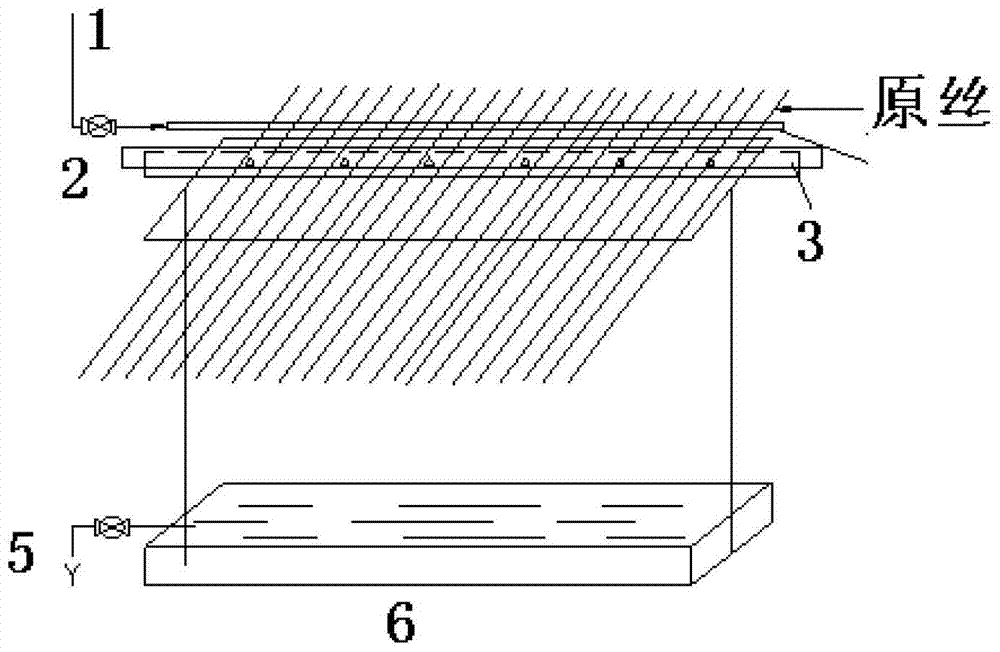

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

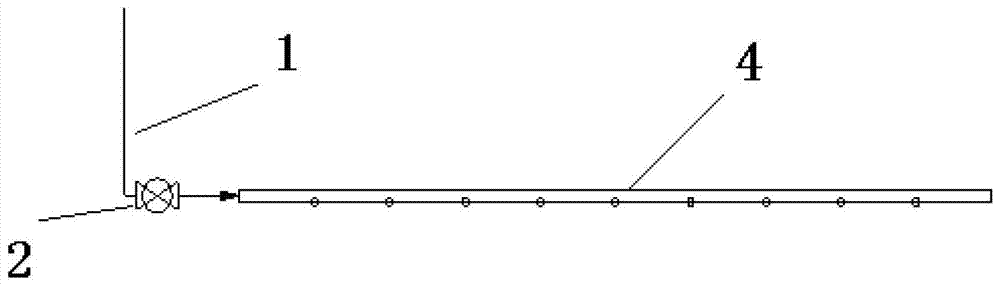

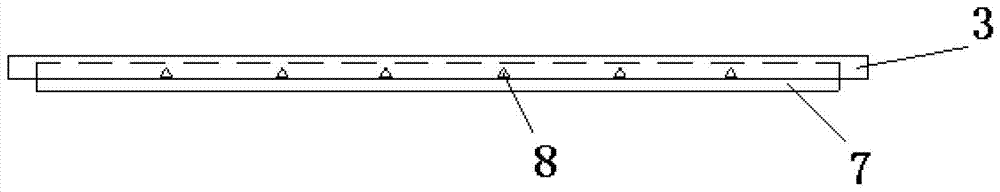

[0016] See figure 1 According to the present invention, the humidification treatment device for withdrawing silk when carbonizing polyacrylonitrile precursors for carbon fibers, the humidification device includes a desalted water delivery pipe 1, a water flow control spherical valve 2, a water spray pipe with holes 4, a water receiving tray 6, The drain pipe 5; the desalted water delivery pipe 1 is connected with the horizontally perforated water spray pipe 4 through the water flow control spherical valve 2, and the perforated water spray pipe 4 is fixed on the top of the water receiving tray 6 through a bracket, and the water receiving tray 6 is provided with Drainage pipe 5, cotton cloth clip 3 are arranged on the below of banded water spray pipe 4, and banded water spray pipe 4, are fixed on the support, and cotton cloth is fixed on the cotton cloth ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com