Ceramic tile adhesive and preparation method thereof

A tile adhesive and compound technology, applied in the field of tile adhesive and its preparation, can solve the problems of prolonging the airing time and not being able to meet the requirements of sticking fine tiles, and achieve the effect of long airing time, firm bonding, and sufficient open time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The present invention also discloses a preparation method of the ceramic tile adhesive described in the above technical solution, comprising the following steps:

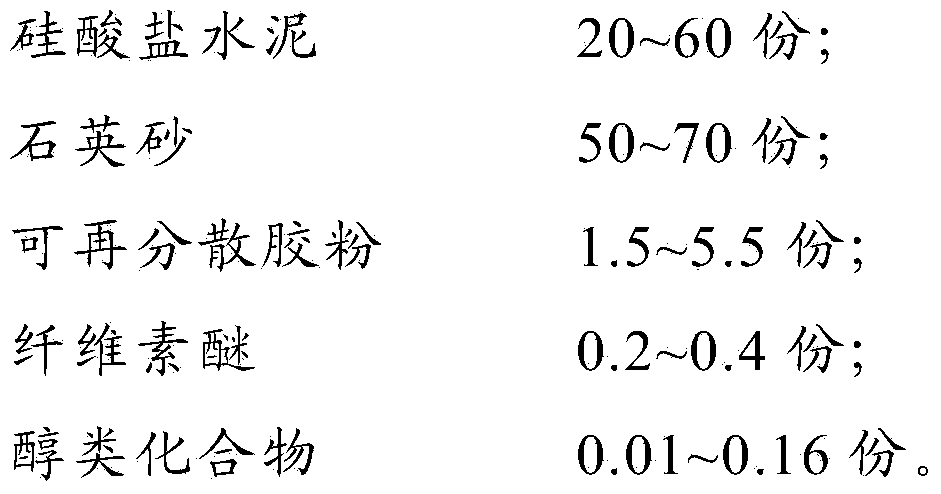

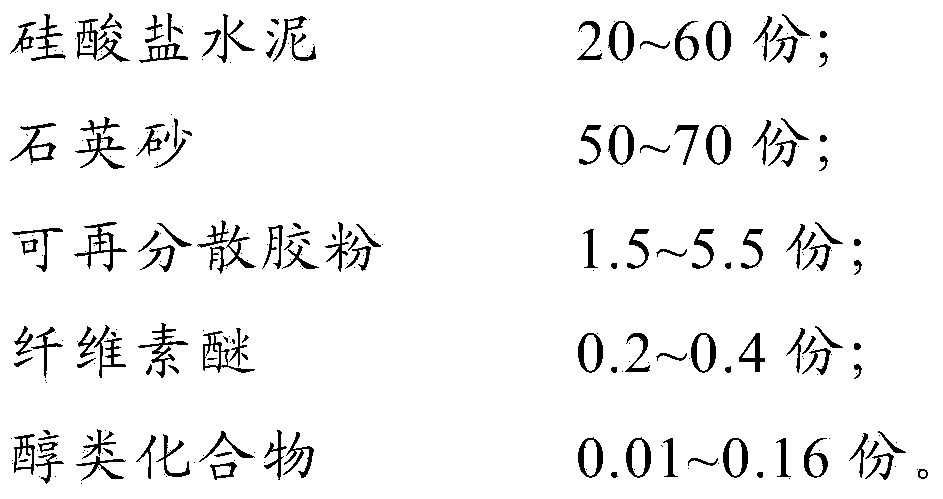

[0030] After mixing 0.01-0.16 parts by weight of alcohol compound and 50-70 parts by weight of quartz sand, add 20-60 parts by weight of Portland cement, 1.5-5.5 parts by weight of redispersible rubber powder and 0.2-0.4 parts by weight of cellulose ether Mix well to get tile adhesive.

[0031] In the present invention, the selected raw materials include Portland cement, quartz sand, redispersible rubber powder, cellulose ether and alcohol compounds. The selection and use of materials for the raw materials will not be described in detail. Preferably, an accelerator is also included to accelerate the hydration speed of cement. In the present invention, there is no special limitation on the source of the accelerator, and commercially available products can be used. The dosage of the accelerator is preferably...

Embodiment 1

[0038] After mixing 0.05kg of stearyl alcohol and 62.45kg of quartz sand evenly, add 35kg of ordinary Portland cement with a hardness of 42.5, 2kg of redispersible rubber powder, 0.2kg of early strength agent and 0.3kg of hydroxypropylmethyl with a viscosity of 40,000 Mix the base cellulose ether evenly to obtain a tile adhesive.

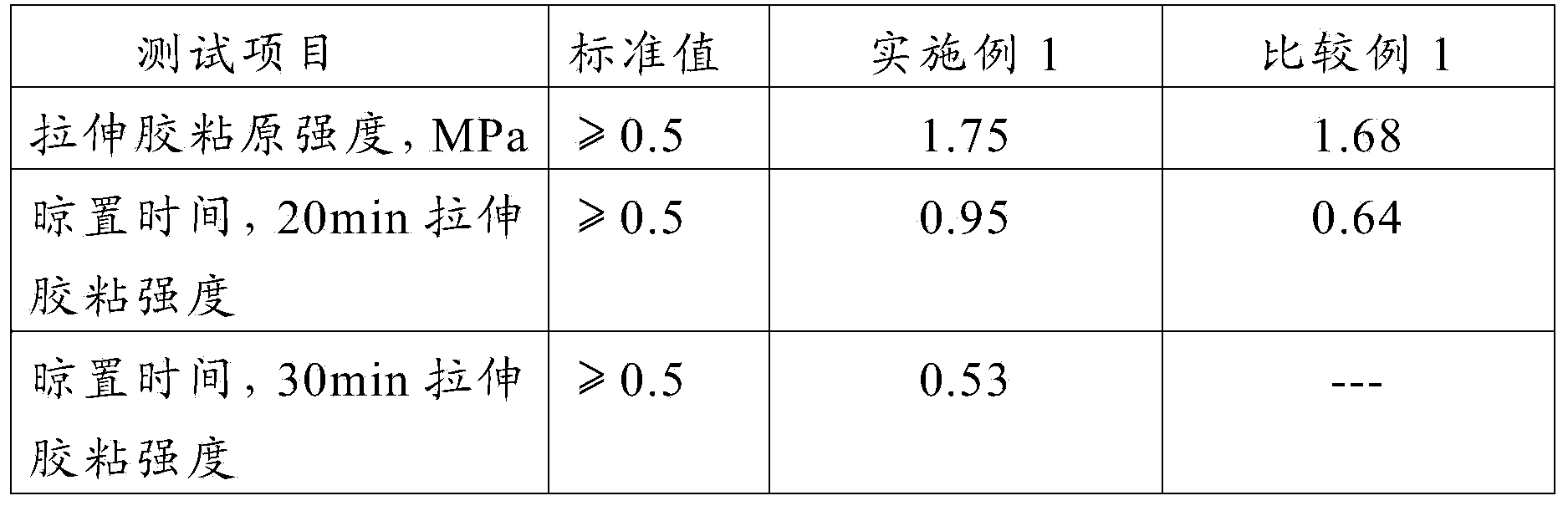

[0039] The obtained tile adhesive and water were uniformly mixed according to the mass ratio of 100:23, and the performance of the tile adhesive was tested according to the provisions of the national building materials industry standard JC / T547-2005, and the results are shown in Table 1.

[0040] The resulting tile adhesive has an open time of up to 50 minutes.

Embodiment 2

[0041] Example 2 After mixing 0.05kg of stearyl alcohol and 62kg of quartz sand evenly, add 35kg of ordinary Portland cement with a hardness of 42.5R, 3kg of redispersible rubber powder, 0.15kg of early strength agent and 0.25kg of cement with a viscosity of 40000 and 45000 The hydroxypropyl methylcellulose ether (weight ratio: 1 / 1) is mixed evenly to obtain tile adhesive.

[0042] The resulting tile adhesive has an open time of up to 50 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com