Aluminum material with enhanced nucleate boiling heat transfer function and preparation method thereof

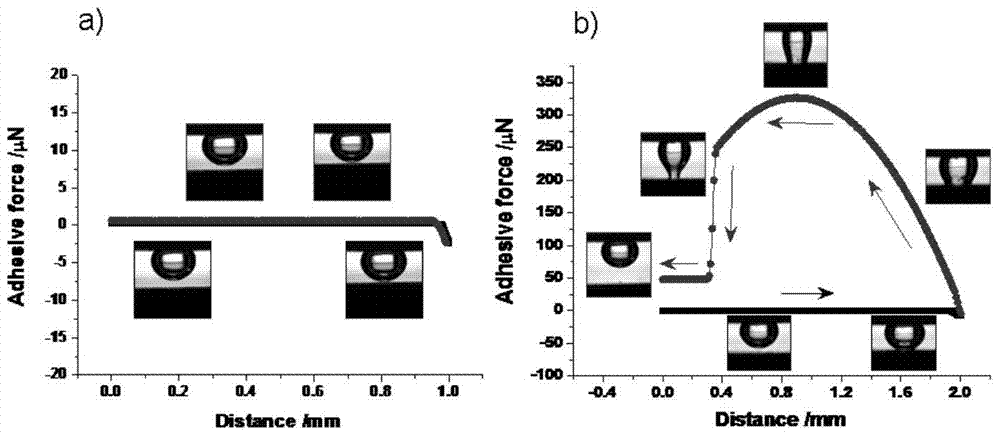

A technology of nucleate boiling and aluminum materials, applied in the field of material science, can solve problems that have not been reported, and achieve the effects of preventing dry wall phenomenon, increasing critical heat load, and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

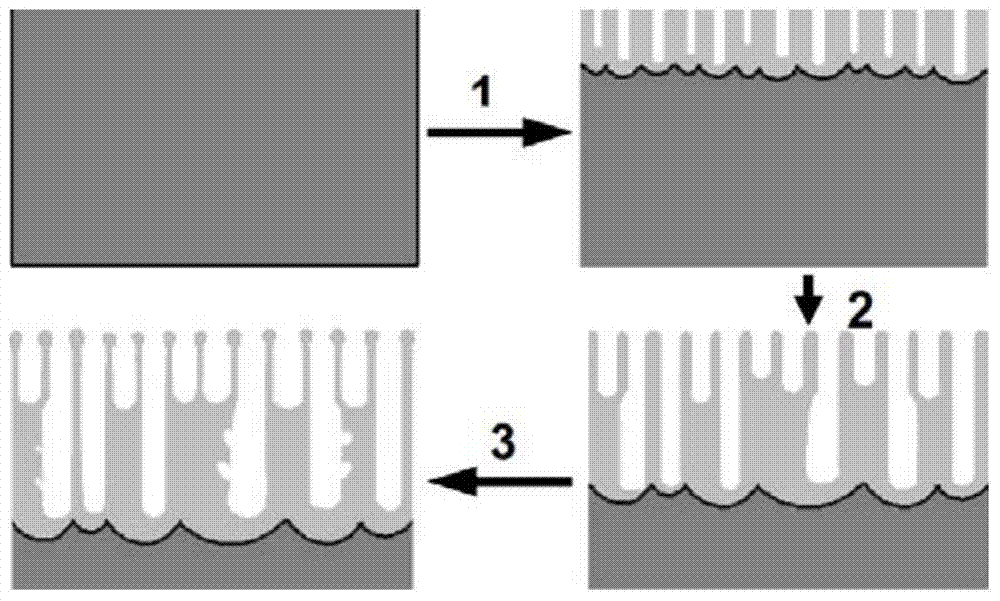

Method used

Image

Examples

Embodiment 1

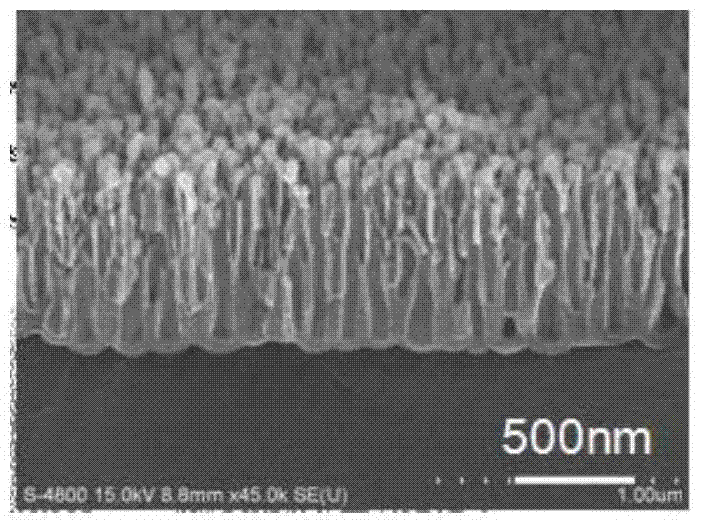

[0041] (1) Remove the organic grease and inorganic impurities on the surface of the aluminum foil by cleaning or grinding, or use it directly without any treatment.

[0042] (2) Using aluminum foil as the anode and platinum electrode as the cathode, control the distance between the two electrodes to 4 cm, and use 2% volume fraction of phosphoric acid aqueous solution as the electrolyte to carry out variable voltage oxidation in a constant temperature water bath at 30 °C (control the appropriate boost The rate increases the voltage from 25 V to 110 V, such as 0.05 V / s), and the current increases to 1.0 A and continues to oxidize for 100 s to obtain an aluminum foil with the function of self-dispelling boiling microbubbles.

[0043] (3) The structure was annealed at 800 °C under the protection of nitrogen in a muffle furnace for 3 h to transform the amorphous alumina porous structure into a crystalline porous structure and improve the stability of the product.

[0044] (4) Suspe...

Embodiment 2

[0047] (1) Remove organic grease and inorganic impurities on the surface of aluminum foil by cleaning or grinding.

[0048] (2) With aluminum foil as the anode and platinum electrode as the cathode, the distance between the two electrodes was controlled to be 5 cm, and 0.3 M oxalic acid aqueous solution was used as the electrolyte to carry out constant current oxidation in a constant temperature water bath at 30 °C for 30 min, and the current was kept at 0.4 A After oxidation for 500 s, the aluminum foil with boiling microbubble self-dispelling function can be obtained.

Embodiment 3

[0050] (1) Remove organic grease and inorganic impurities on the surface of aluminum foil by cleaning or grinding.

[0051] (2) Using aluminum foil as the anode and platinum electrode as the cathode, the distance between the two electrodes was controlled to be 4 cm, and 0.3 M sulfuric acid aqueous solution was used as the electrolyte to carry out variable voltage oxidation in a constant temperature water bath at 30 °C (control the appropriate boost rate to make The voltage is increased from 25 V to 110 V, such as 0.1 V / s), and oxidized for 60 s, an aluminum foil with boiling microbubble self-dispelling function can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com