Electric spraying type aviation gasoline engine

An aviation gasoline and engine technology, applied in engine components, engine control, machine/engine, etc., can solve the problems of difficult normal operation of the engine, poor fuel economy, difficult gasoline engine, etc., to improve cruising altitude, improve reliability, enhance The effect of overall strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

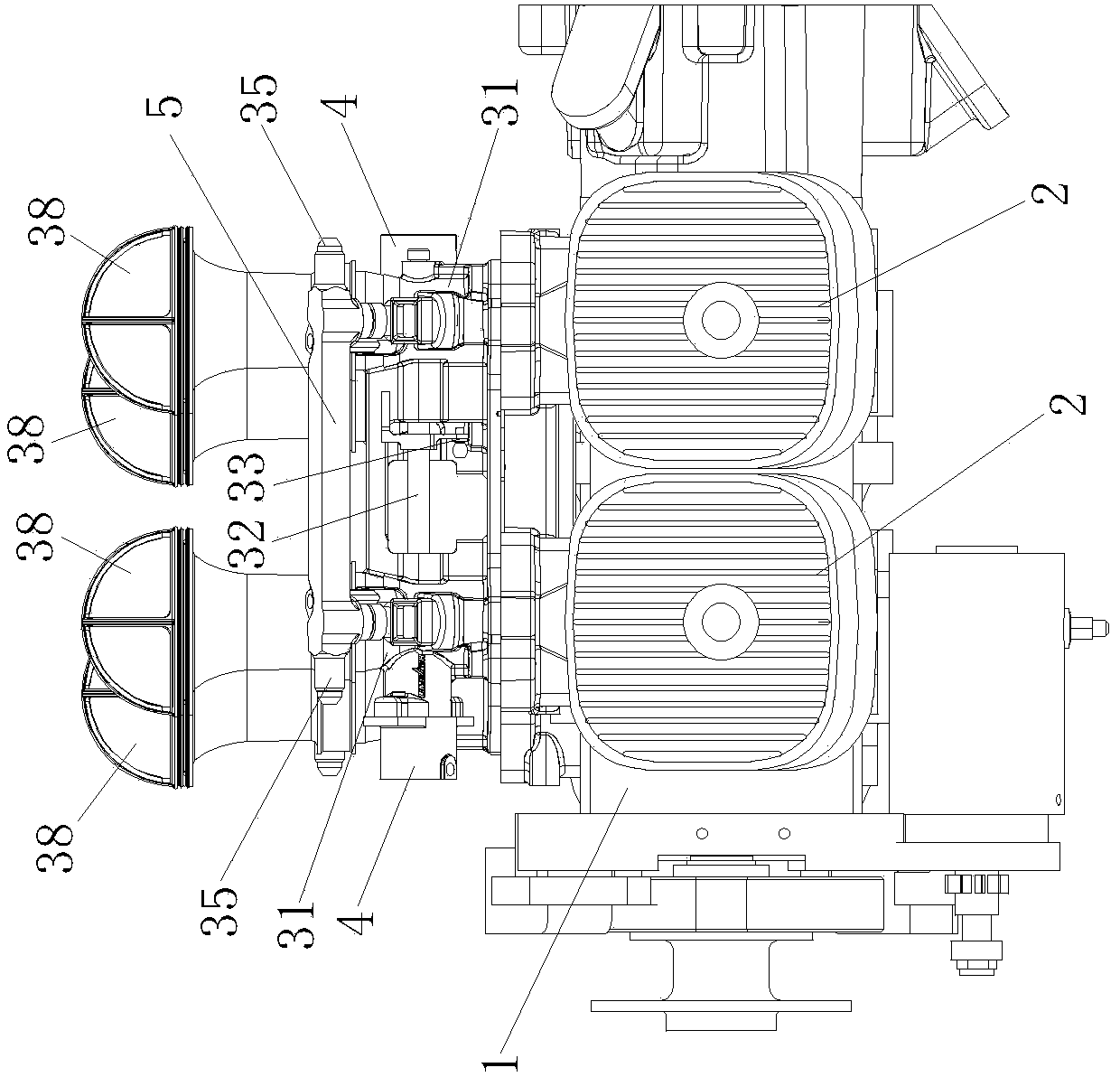

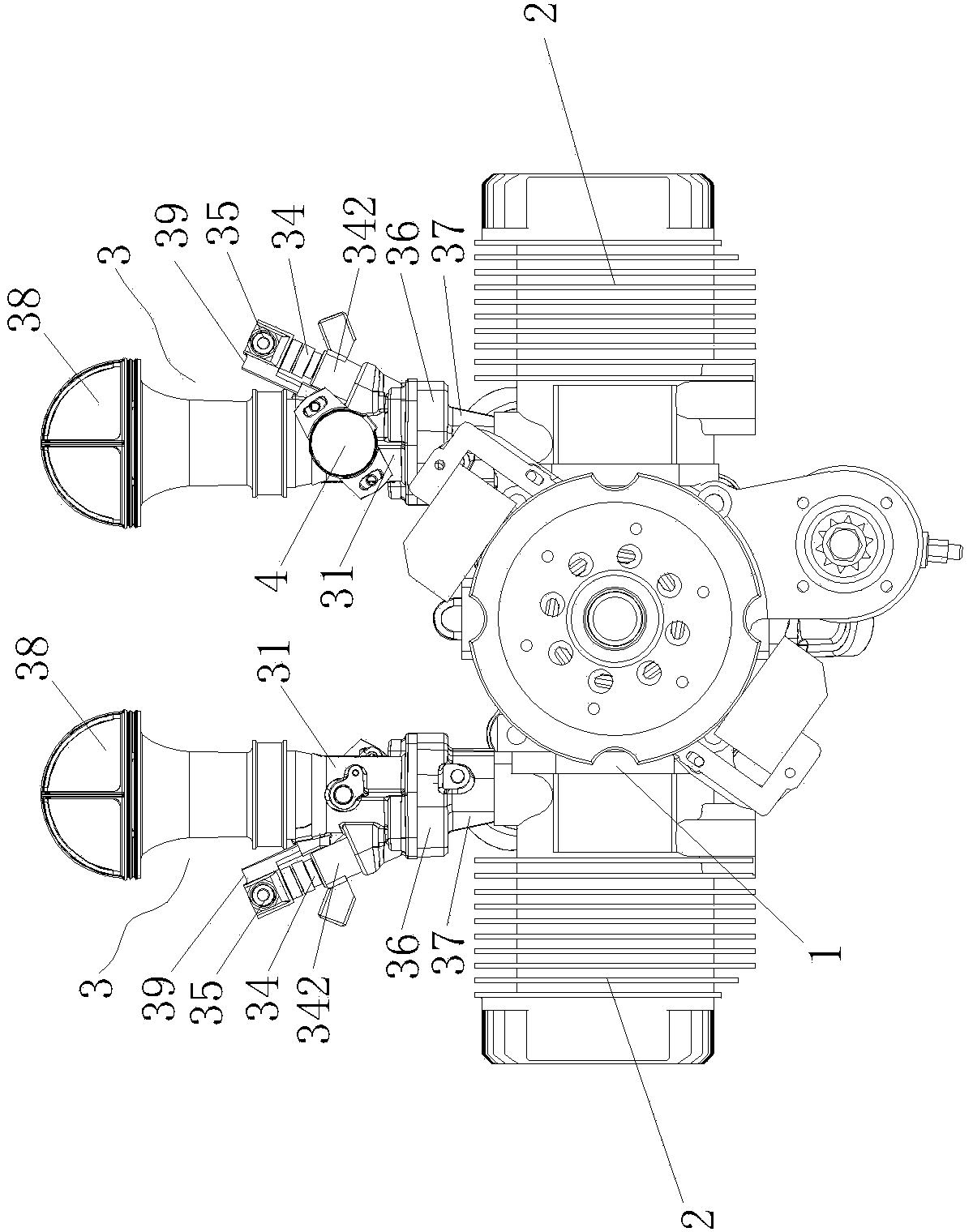

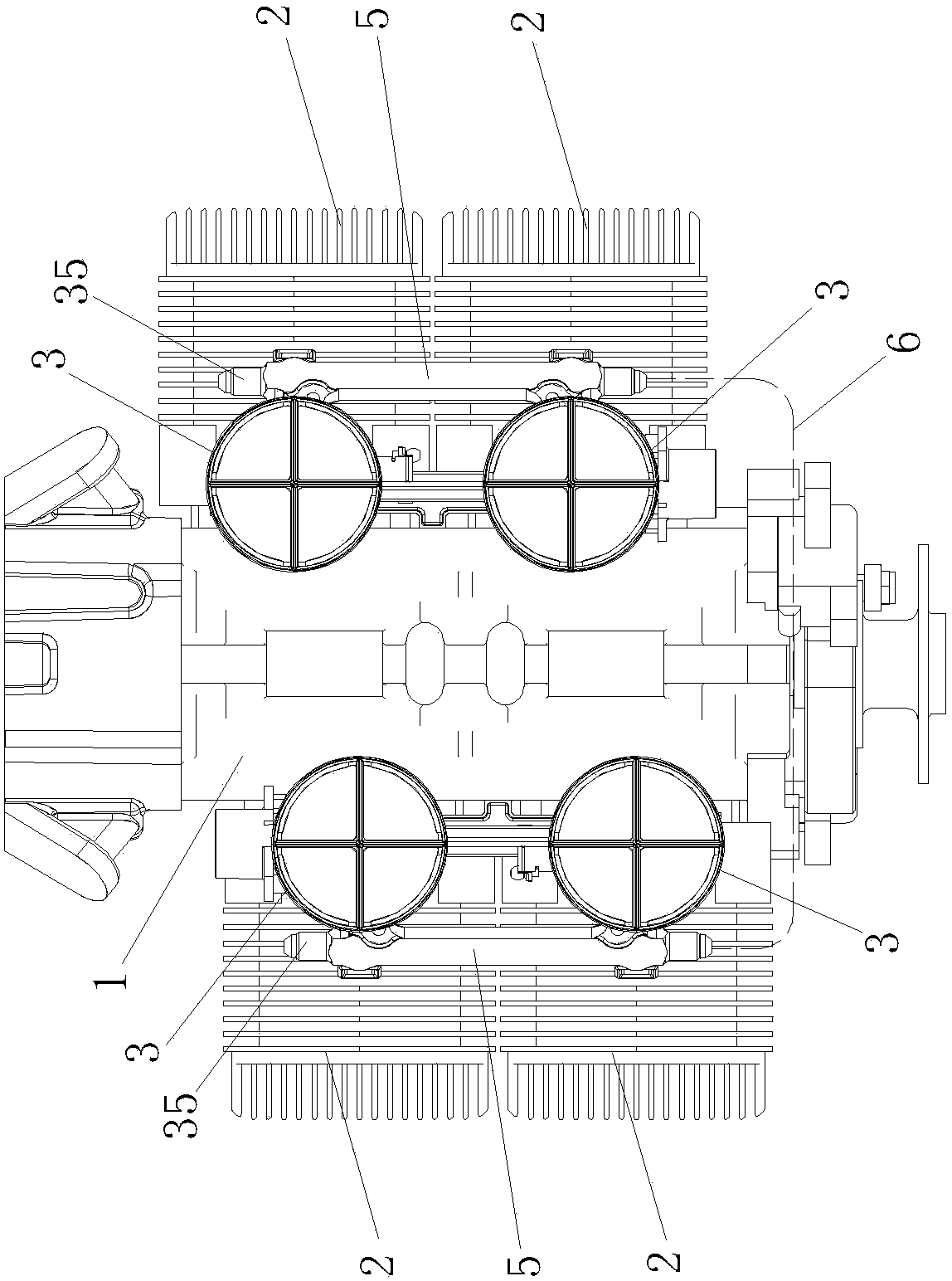

[0021] Figure 1 to Figure 6 Shown, a kind of electrospray type aviation gasoline engine comprises crankcase 1, four cylinder blocks 2, and four cylinder blocks 2 are contained in the both sides of crankcase 1 horizontally opposite in pairs, and the intake of four cylinder blocks 2 The air ports are all set upwards, and the air inlet of each cylinder block 2 is connected with an electric fuel injection mechanism 3, and the electric fuel injection mechanism 3 includes an intake pipe 31, a throttle shaft 32, a driving crank arm 33, a fuel injector 34, and an intake valve. The oil pipe 35 and the throttle shaft 32 are arranged in the middle of the intake pipe 31 along the radial direction of the intake pipe 31. The part where the throttle shaft 32 is located in the inner hole of the intake pipe 31 is fixedly connected with a throttle, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com