Robot for installing groove-type large-caliber pipeline connector in deepwater complex environment

A technology for large-diameter pipes and operating robots, which is applied in the field of large-diameter pipe grooved connector installation and operating robots, and can solve the constraints of low automation, reliability, control performance and operating flexibility, and the scope of application of grooved connectors , Install the problem of lagging research and development of operating robots, achieve high mobility and flexibility, ensure balance and stability, and simplify the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be described in detail below in conjunction with the accompanying drawings.

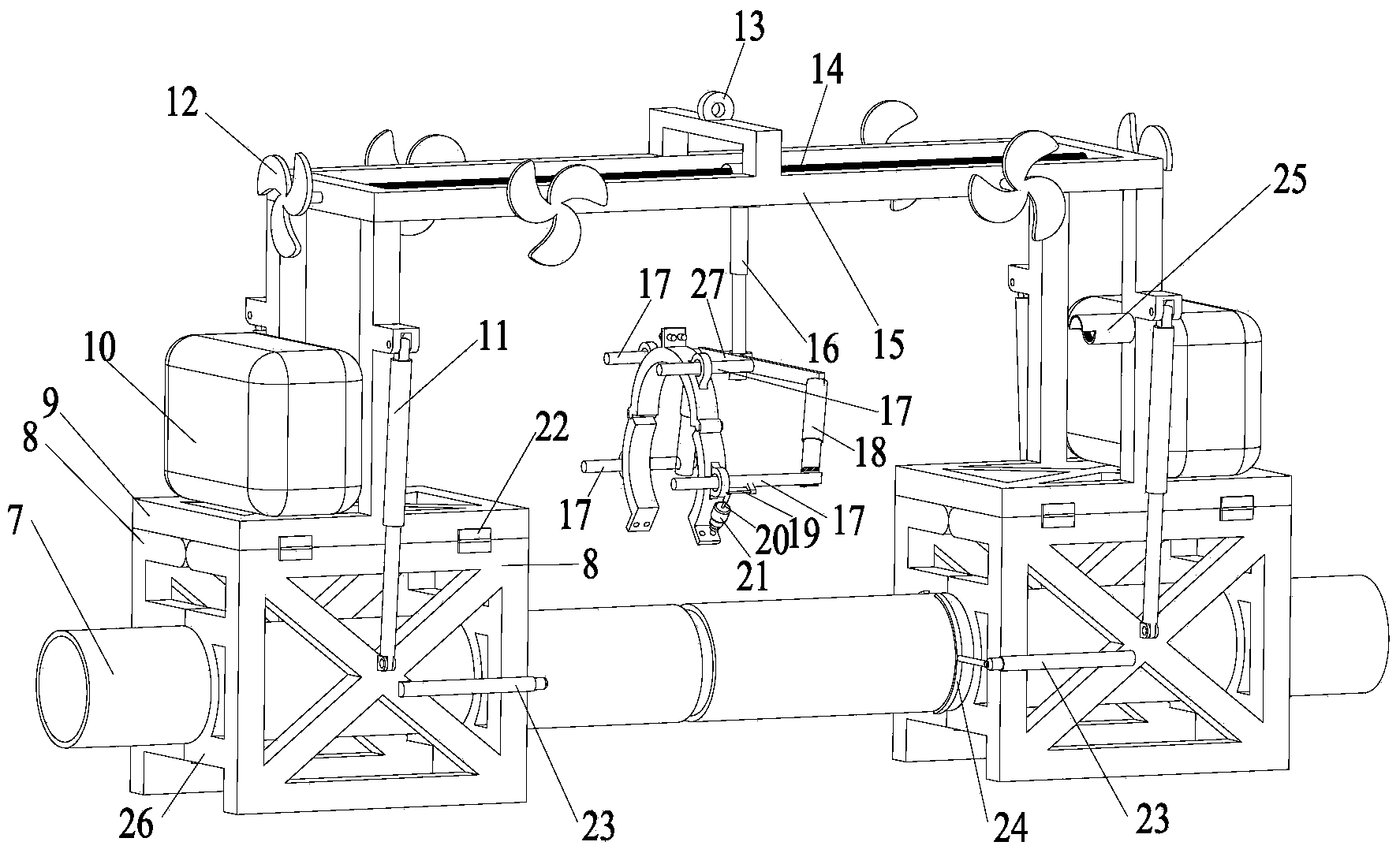

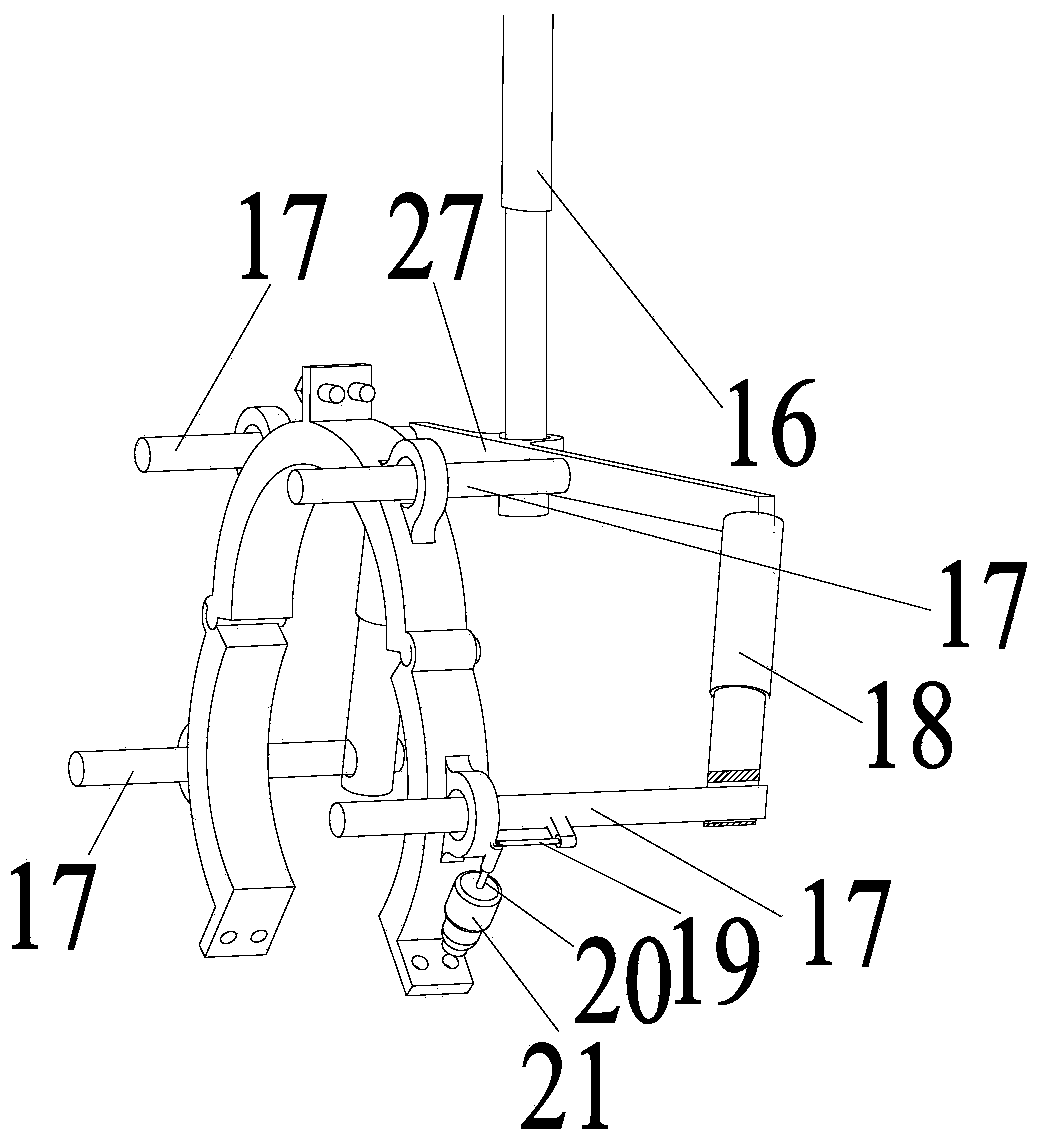

[0060] Such as figure 1 , figure 2 As shown, the operation robot for installing large-diameter pipeline grooved connectors in complex deep water environments of the present invention includes a water pressure sensor connected to an external mother ship in communication, a power supply line connected to an external mother ship, and a hydraulic oil delivery pipeline; it is characterized in that , the overall shape is similar to that of a gantry crane, including the beam part, the left mechanism, the right mechanism and the mechanical arm; the left mechanism and the right mechanism are both box-shaped frame structures, and the left and right hands are symmetrical. end;

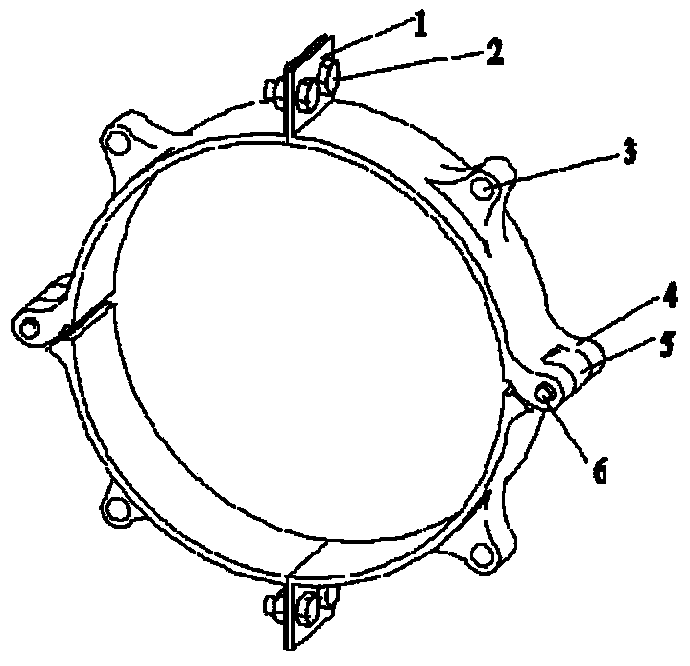

[0061] Such as Figure 4 As shown, the above-mentioned left mechanism includes a fixed side wing 8 and a fixed upper plate 9; the above-mentioned fixed side wing 8 is an opening and closing structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com