Bulb lamp structure

A technology for lamp holders and lamp holders, applied in point light sources, lighting and heating equipment, electric light sources, etc., can solve the problems of non-automatic implementation, high production cost, and small lighting range, and achieve good heat dissipation effect and high heat dissipation efficiency High, wide-range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

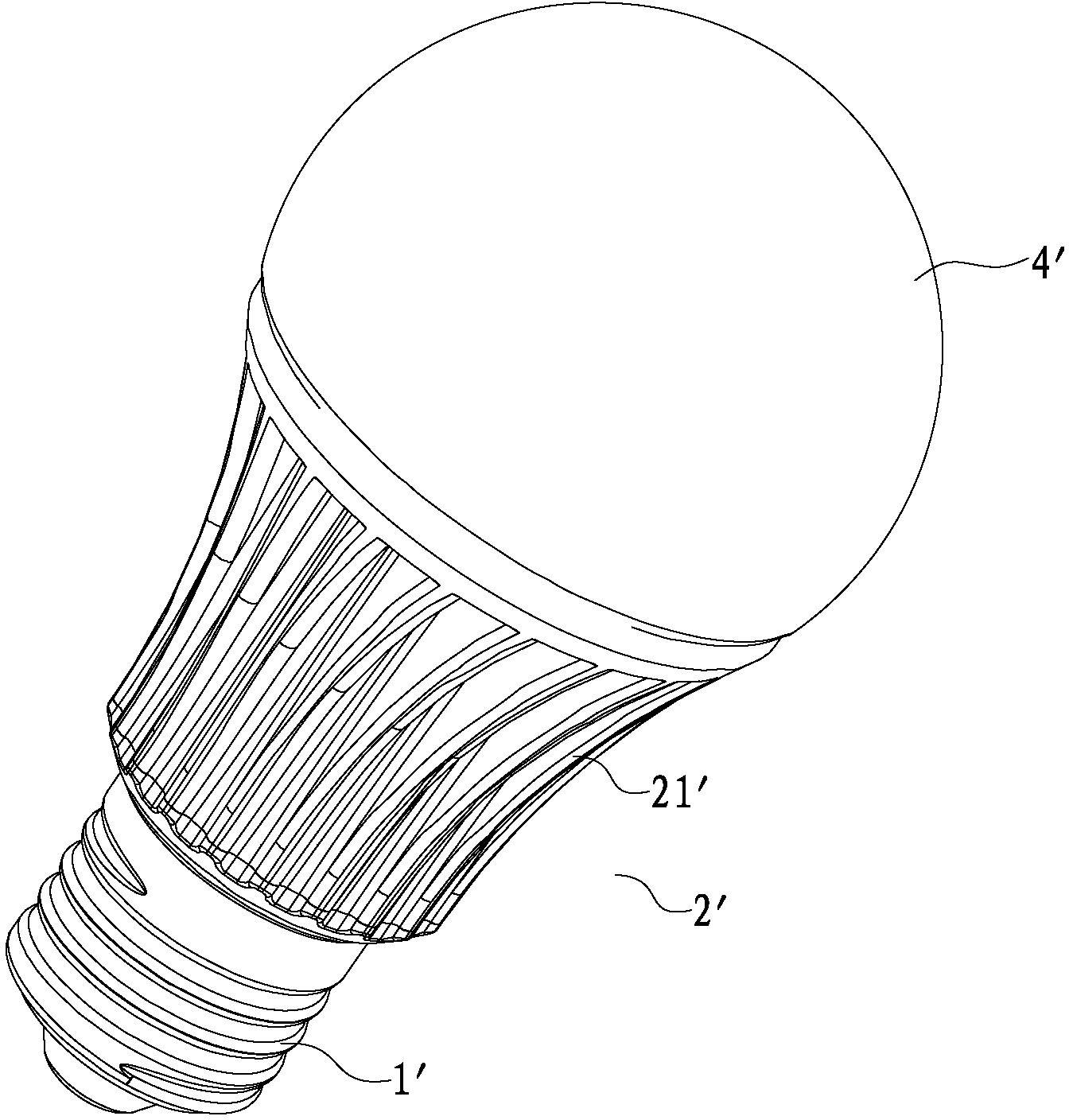

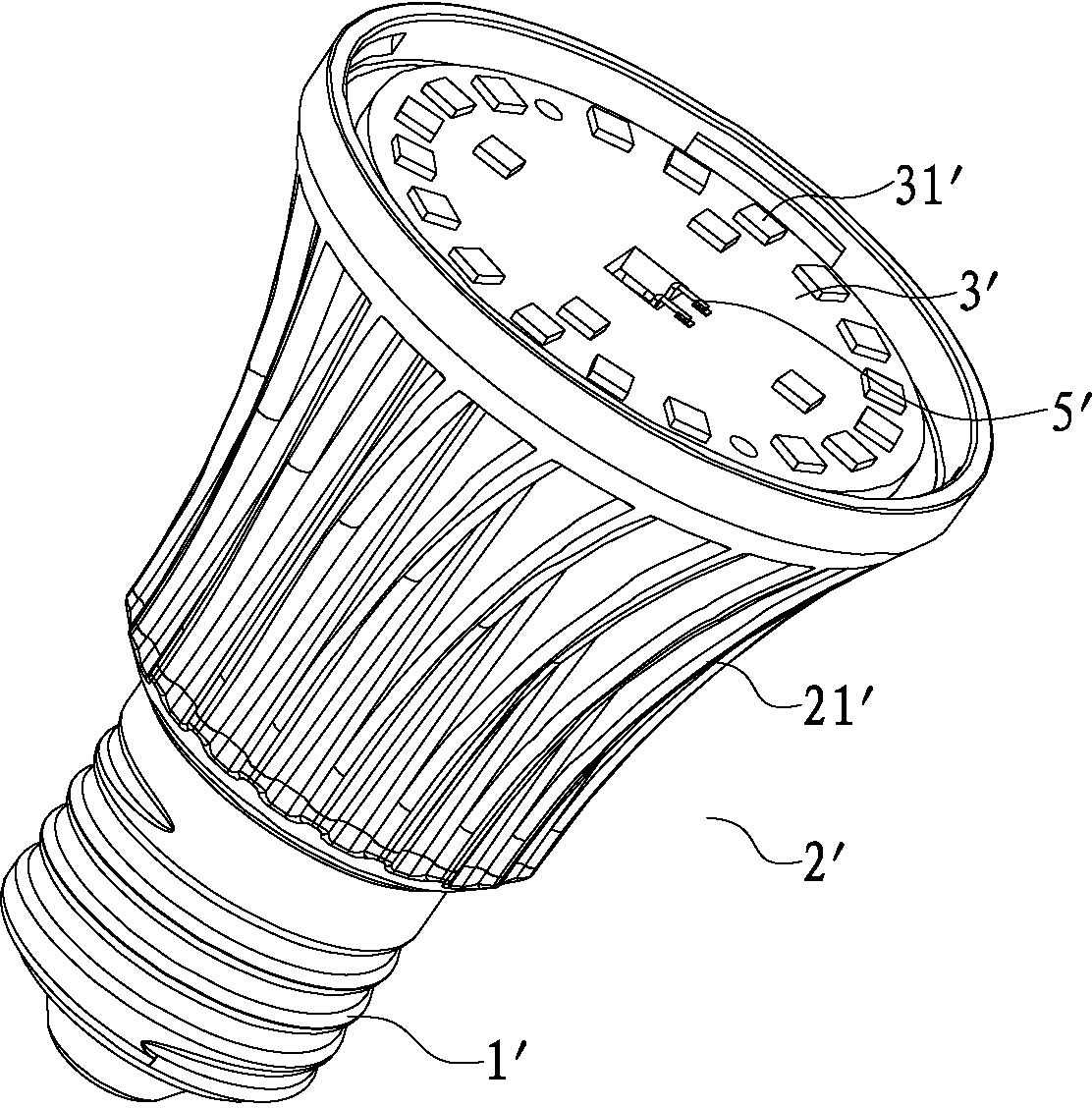

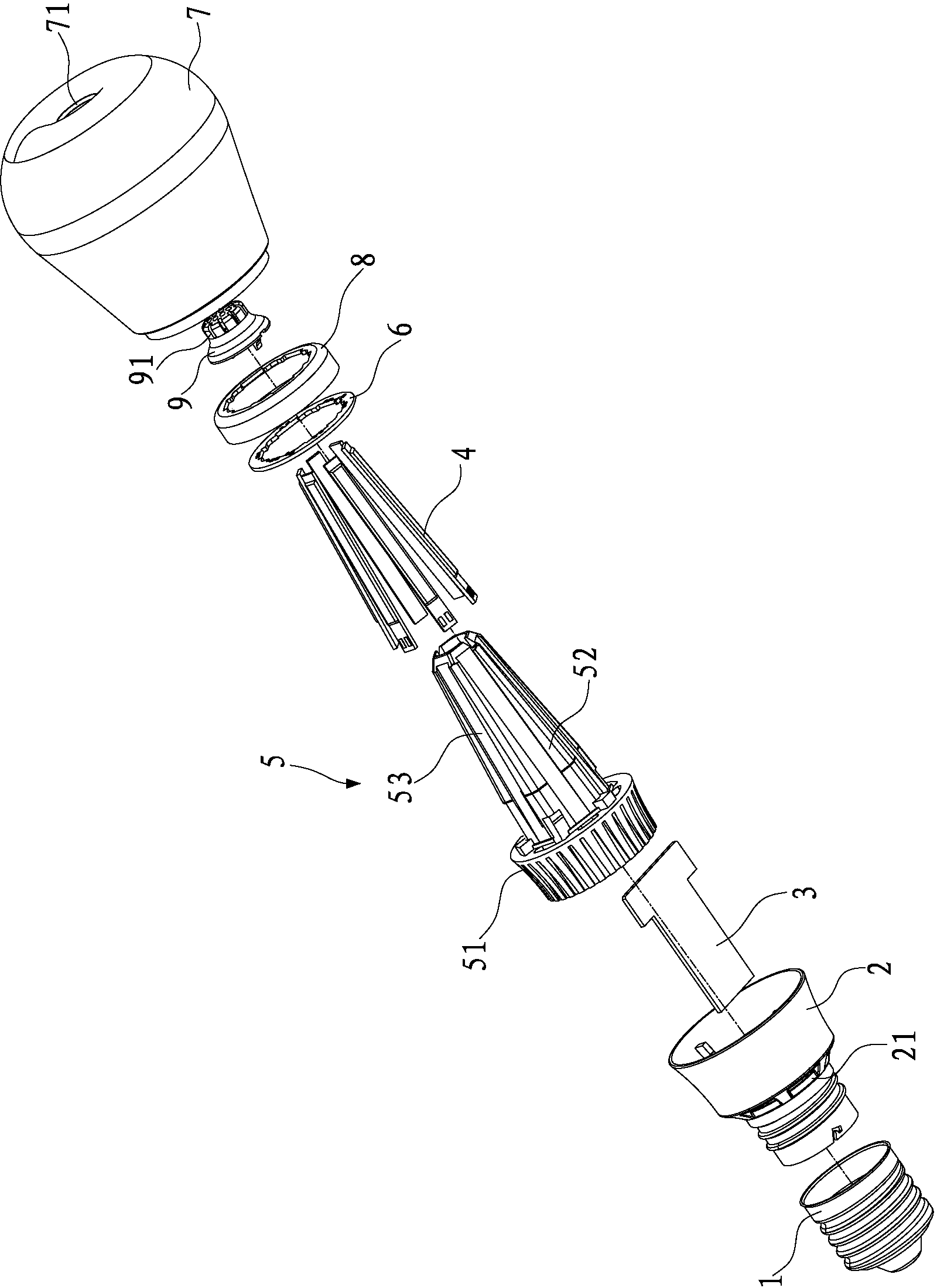

[0019] like Figure 3 to Figure 6 As shown, the present invention discloses a light bulb structure, which includes a lamp base 1, a lamp holder 2, a circuit board 3 for driving LED chips to work, several chips 4 with LED lamp beads distributed thereon, a heat sink 5, a A double-sided board 6 connecting the chip 4 and the circuit board 3 , and a bulb 7 .

[0020] The lamp cap 1 is matched with the lower end of the lamp holder 2, and the lamp holder 2 is provided with an air inlet. In this embodiment, an air inlet 21 is distributed on the lower edge of the lamp holder 2 adjacent to the lamp holder 1, and the lower part of the radiator 5 forms a ring shape. The cover base 51 fits in the lamp base 2, and the upper end of the ring-shaped cover base 51 extends upward at intervals with several sheet-shaped substrates 52, each sheet-shaped substrate 52 encloses a chamber 53, and the chamber 53 is from bottom to top Form a tapered state, so that the upper end of the chamber 53 is form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com