Full-digital type small-rate sight object angle testing equipment

An all-digital, testing equipment technology, applied in the field of optical measurement, can solve the problems of difficulty in ensuring high-precision detection, low resolution in a large field of view, and a small field of view, so as to improve the efficiency of sight testing and ensure Test accuracy and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

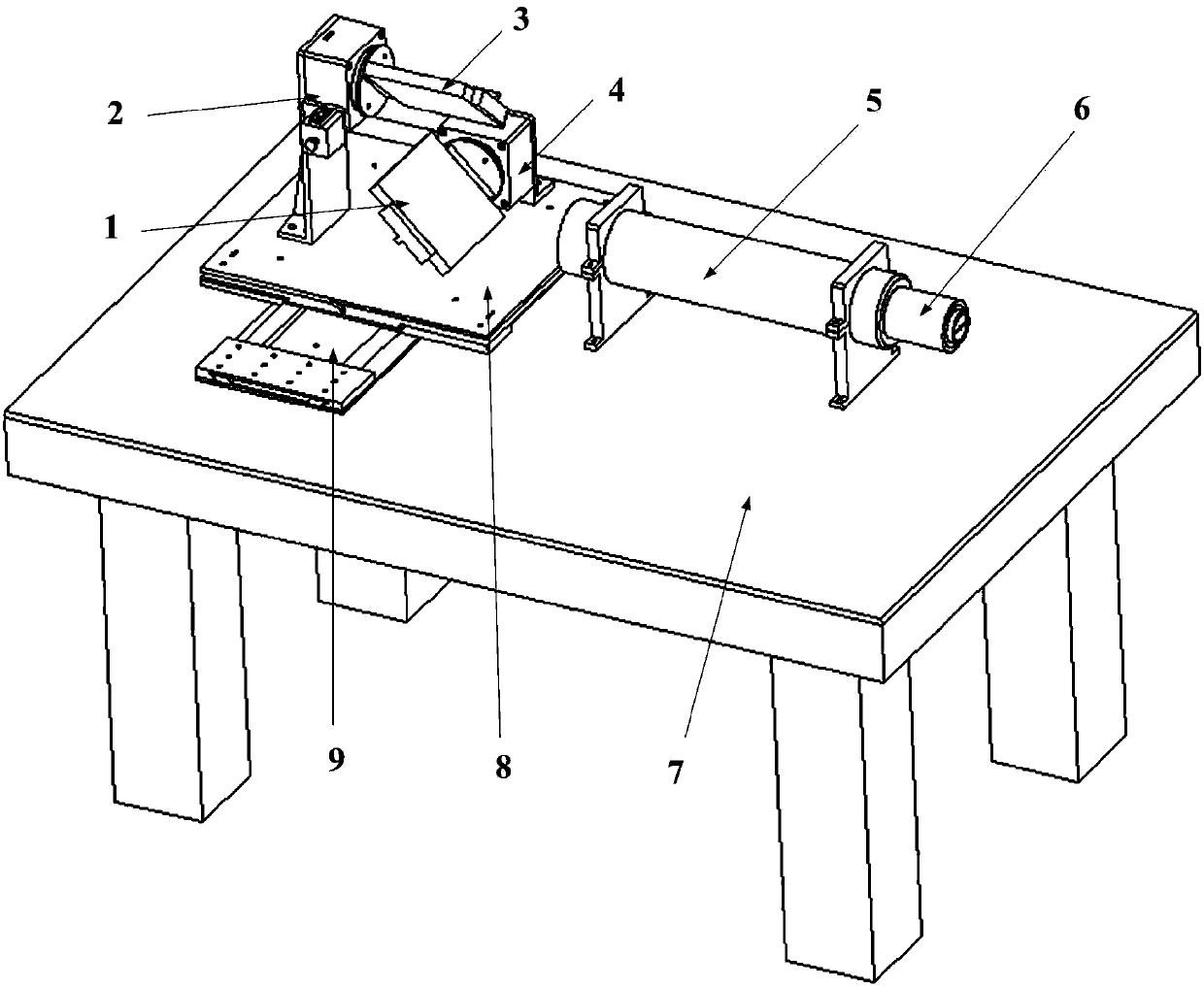

[0017] The main components of the all-digital small magnification sight object square angle test equipment include: azimuth plane reflector 1, pitch digital turntable 2, pitch plane reflector 3, azimuth digital turntable 4, collimator main body 5, digital reticle assembly 6, Optical platform 7, X-direction numerically controlled translation stage 8 and Y-direction numerically controlled translation stage 9 (as attached figure 1 shown). Among them, the collimator main body 5 and the digital reticle assembly 6 constitute a collimator for simulating an infinite target; the azimuth digital turntable 4 and the azimuth plane reflector 1 constitute an azimuth reading and field of view expansion assembly; the pitch digital turntable 2 and the pitch plane reflector The mirror 3 constitutes a pitch reading and field of view expansion assembly.

[0018] The digital reticle assembly 6 is mainly composed of high-resolution digital light processing (DLP) devices, and can also be composed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com