On-line intelligent monitoring method of concrete work performance on construction site

A work performance, construction site technology, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve problems such as poor adjustment timeliness, avoid excessive deviation, fully automate the collection process, and work in a simple way.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

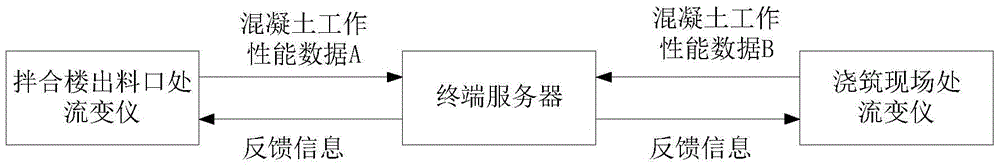

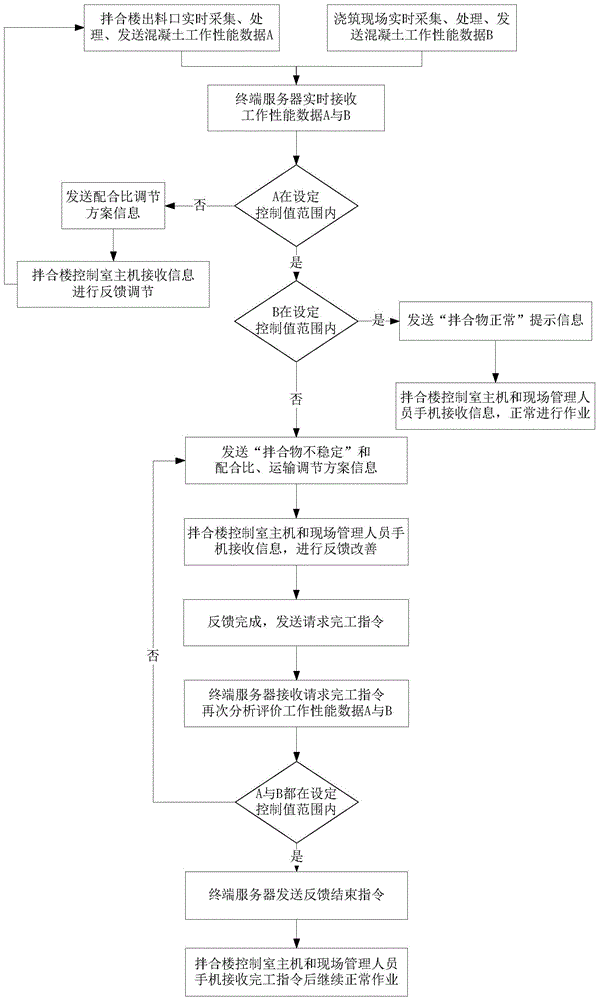

[0031] Embodiment: the system block diagram of the present embodiment is as figure 1 As shown, it includes the terminal server and the rheometer at the outlet of the mixing building and the rheometer at the pouring site that are connected in communication with it. Communication between the rheometer and the terminal server for concrete work performance data and feedback information.

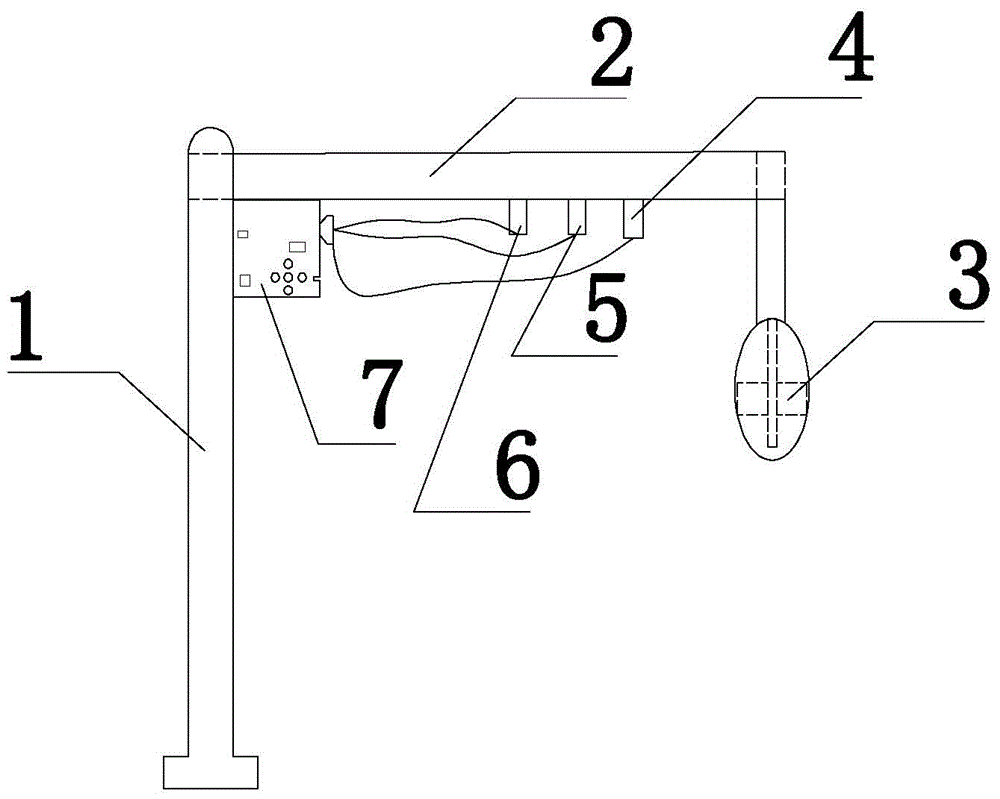

[0032] Among them, the rheometer at the outlet of the mixing building and the rheometer at the pouring site are all manipulator rheometers, such as figure 2 As shown, it includes a vertical frame 1, a manipulator 2, a rotating shaft and a welding blade 3, a torque sensor module 4, a distance sensor module 5, a temperature and humidity sensor module 6, and an intelligent module 7. The vertical frame 1 and the manipulator 2 are free to expand and contract, and the manipulator 2 can rotate horizontally around the vertical frame 1. The rotating shaft and the welding blade 3 are located at the end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com