Display panel and manufacturing method thereof

A manufacturing method and display panel technology, applied in semiconductor/solid-state device manufacturing, optics, instruments, etc., can solve the problems of increasing process cost and difficulty of process, and achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

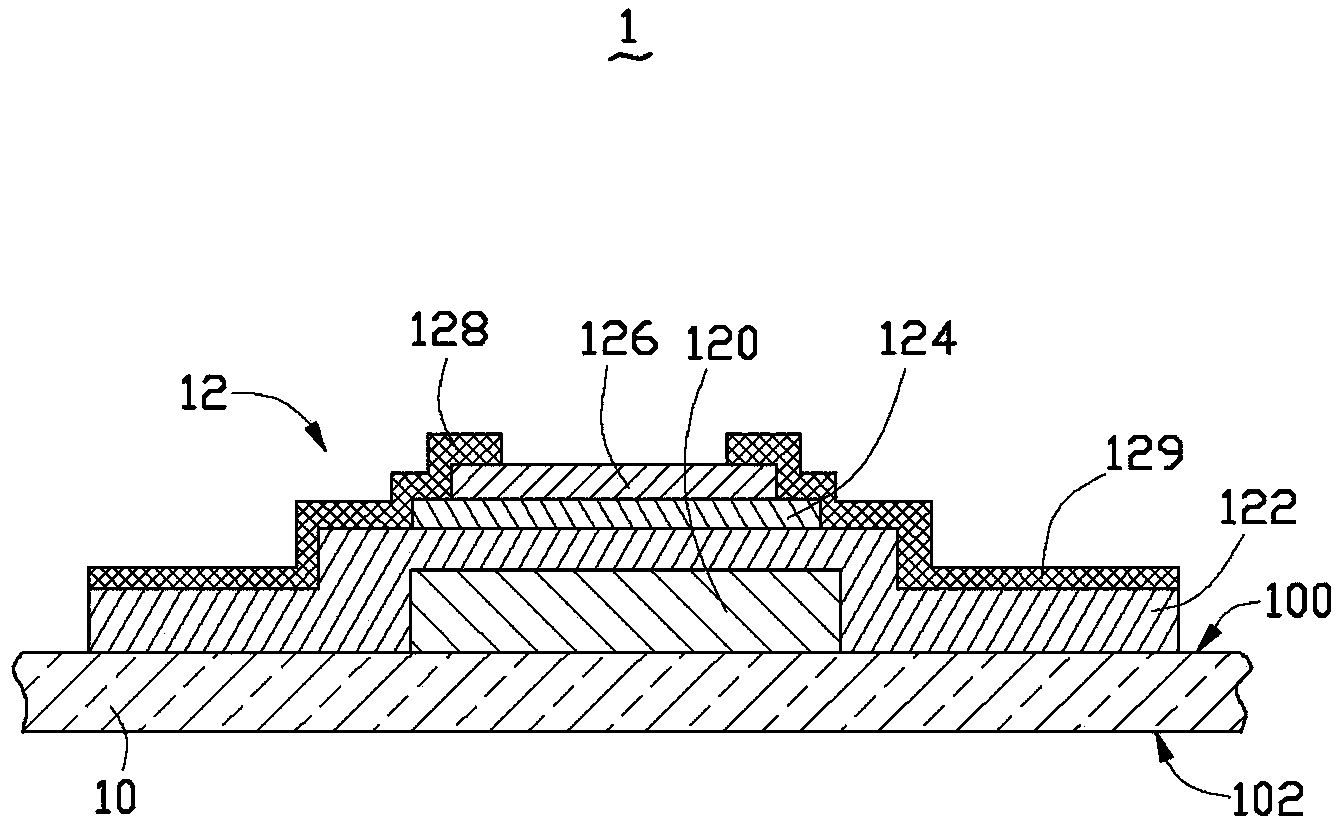

[0025] Such as figure 1 As shown, the display panel 1 provided by the embodiment of the present invention includes a substrate 10 and a plurality of thin film transistors 12 (Thin Film Transistor, TFT) disposed on the substrate 10 and arranged in an array. The TFT 12 includes a gate 120 , a gate insulating layer 122 , a semiconductor pattern 124 , an etch stop pattern 126 , a source 128 and a drain 129 . The gate 120 is disposed on the substrate 10 and extends along a first direction A. Referring to FIG. The gate insulating layer 122 covers the gate 120 . The semiconductor pattern 124 is disposed on the gate insulating layer 122 . The etch stop pattern 126 covers the channel region of the semiconductor pattern 124 to prevent the etchant from damaging the channel region of the semiconductor pattern 124 during the fabrication of the display panel 1 . The source 128 and the drain 129 are respectively disposed on opposite sides symmetrical to the gate 120 and partly cover the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com