Hydraulic control valve assemblies and control systems for water networks

A technology of hydraulic control system and hydraulic control valve, applied in the direction of control/regulation system, auxiliary non-electric fluid pressure control, fluid pressure control, etc., can solve the problems of cost increase, cost increase, maintenance cost increase, etc., and achieve enhanced modules effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

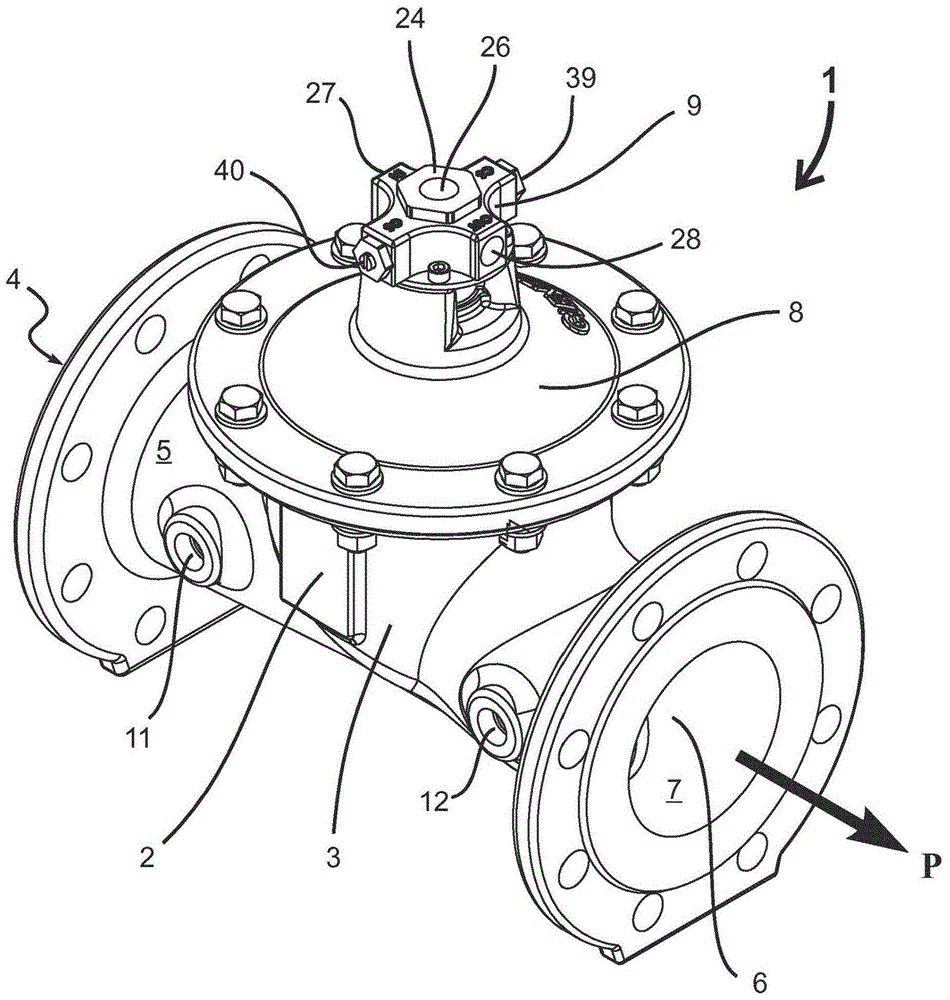

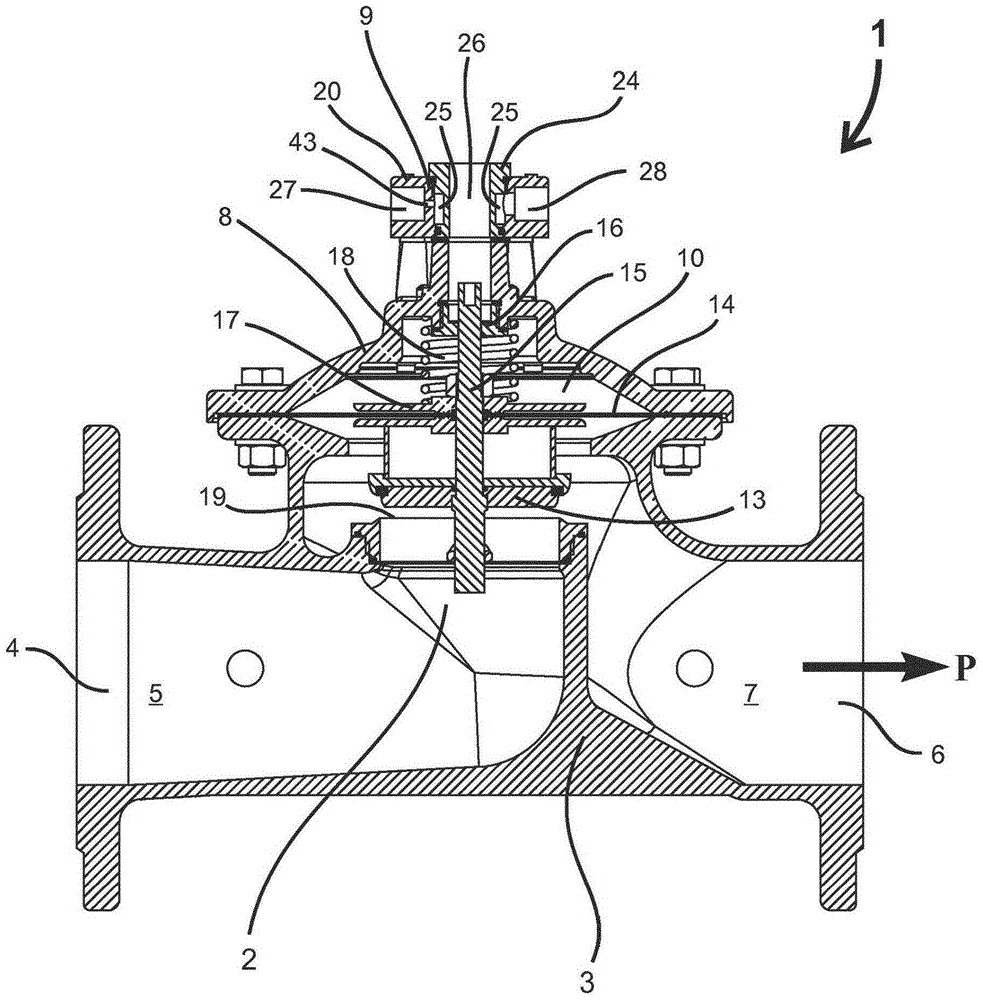

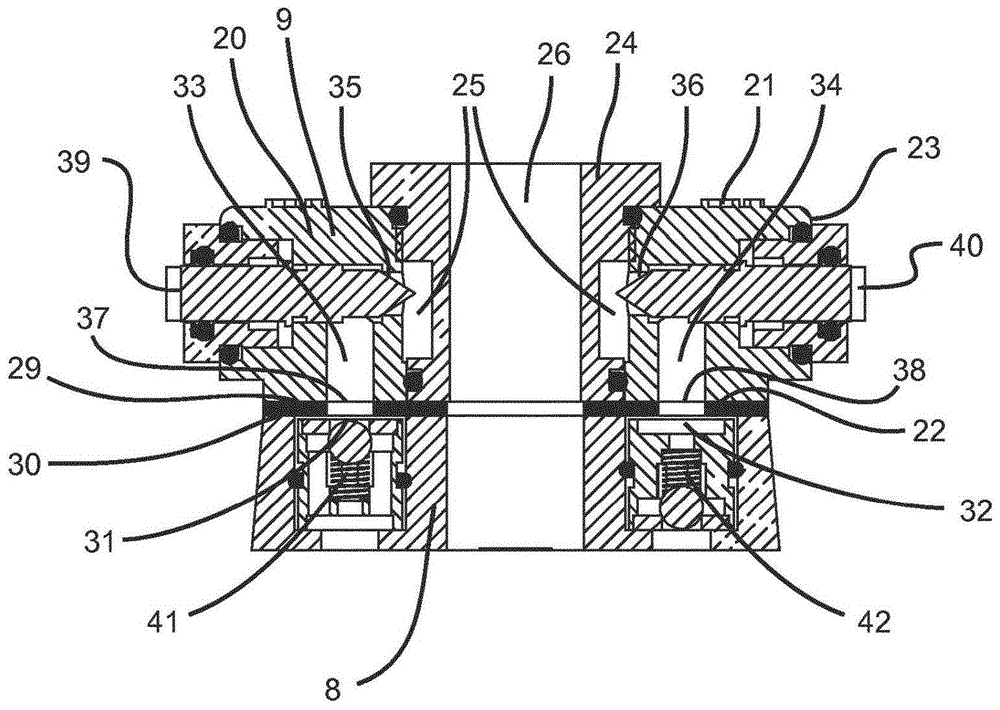

[0058] figure 1 Shown is a perspective view of a hydraulic control valve assembly 1 for use in a hydraulic control system for performing control functions in a water supply network in response to changes in water pressure fluctuations. The hydraulic control valve assembly 1 comprises a control valve 2 comprising a valve body 3 defining from an inlet 4 on the high pressure side 5 of the control valve 2 to a low pressure side 7 of the control valve 2 in the lower part of the control valve 3 Main channel on Exit 6. The general direction of the main flow M is indicated by the arrow P and coincides with the longitudinal direction of the hydraulic control valve assembly 1 . The valve body also comprises a first tap 11 for branching off the control flow C from the main flow M at the high pressure side 5 of the control valve 2, and a second tap 12. For returning the control flow C to the main flow at the low pressure side 7 of the control valve 2 . In vertical direction, the valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com