Tobacco perfuming agent prepared through molecular distillation treatment of extractum obtained through Maillard reaction from inferior tobacco leaves, preparation method and application of tobacco perfuming agent

A technology of Maillard reaction and molecular distillation, which is applied in the preparation of tobacco, processing tobacco, tobacco, etc., to achieve the effect of simple application, increased roasting aroma, and soft and delicate smoke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

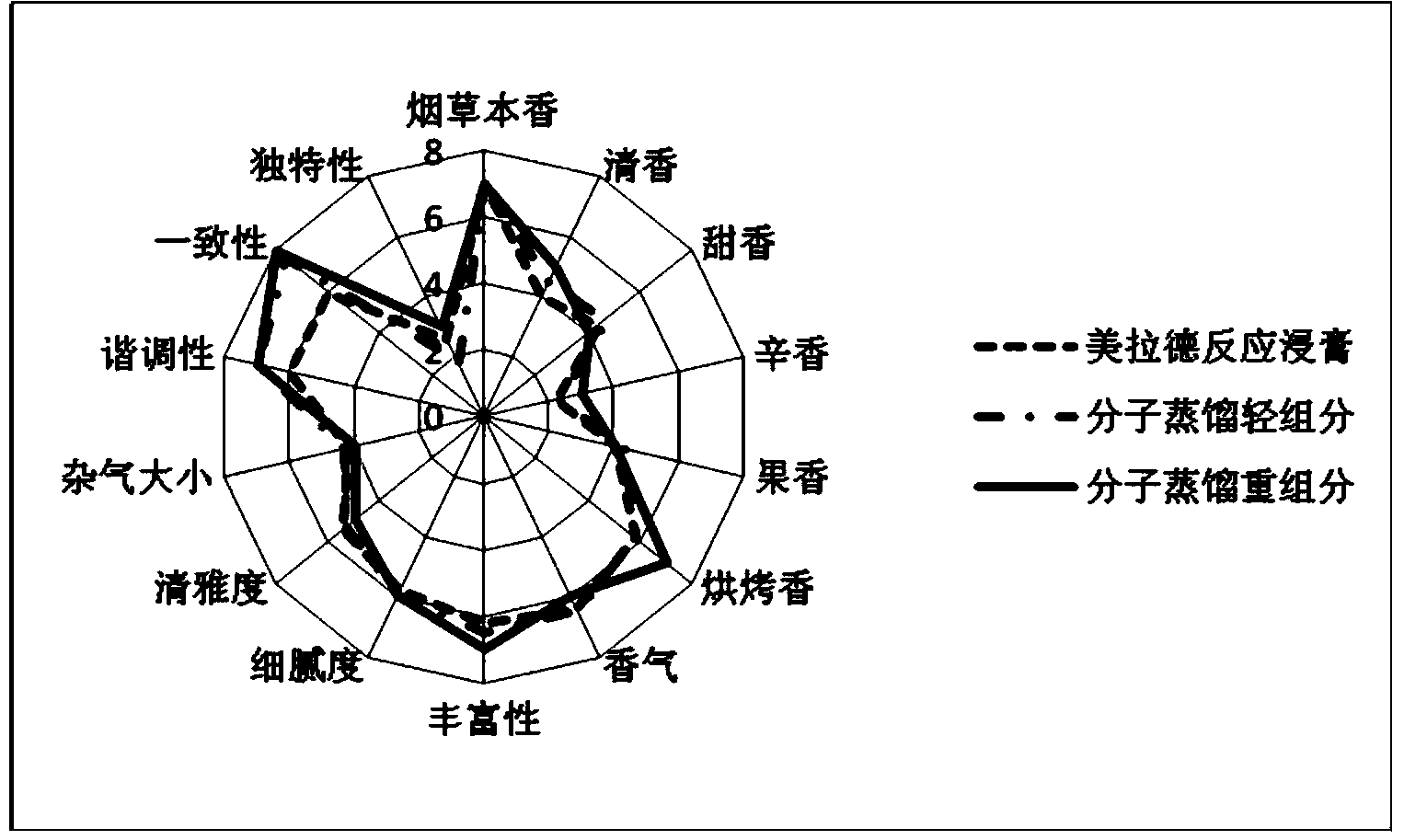

[0025] Crush 3 kg of low-grade tobacco leaves, add water and stir, cook at 100°C for 30 minutes; treat with compound enzyme at 50°C for 2 hours; cook at 100°C for 30 minutes to inactivate the enzyme; add red dates to the tobacco at a ratio of 20:5:3:5:1 Powder, ebony, jujube kernel powder, licorice and other auxiliary materials are subjected to Maillard reaction at 100-120°C; extracted with 95% alcohol, filtered, and the filtrate is vacuum concentrated at 50°C to obtain ethanol extract. Then, using ethanol extract as raw material, the optimum conditions for the preparation of tobacco essential oil by molecular distillation were preliminarily determined through experiments: system vacuum 0.1mbar, wiper speed 400r / min, sample flow rate 2.5mL / min, distillation temperature 75℃. Finally, the heavy component and light component of the essential oil obtained by molecular distillation are added to the tobacco in a ratio of 1 / 10,000. figure 1 It can be seen that compared with the ethan...

Embodiment 2

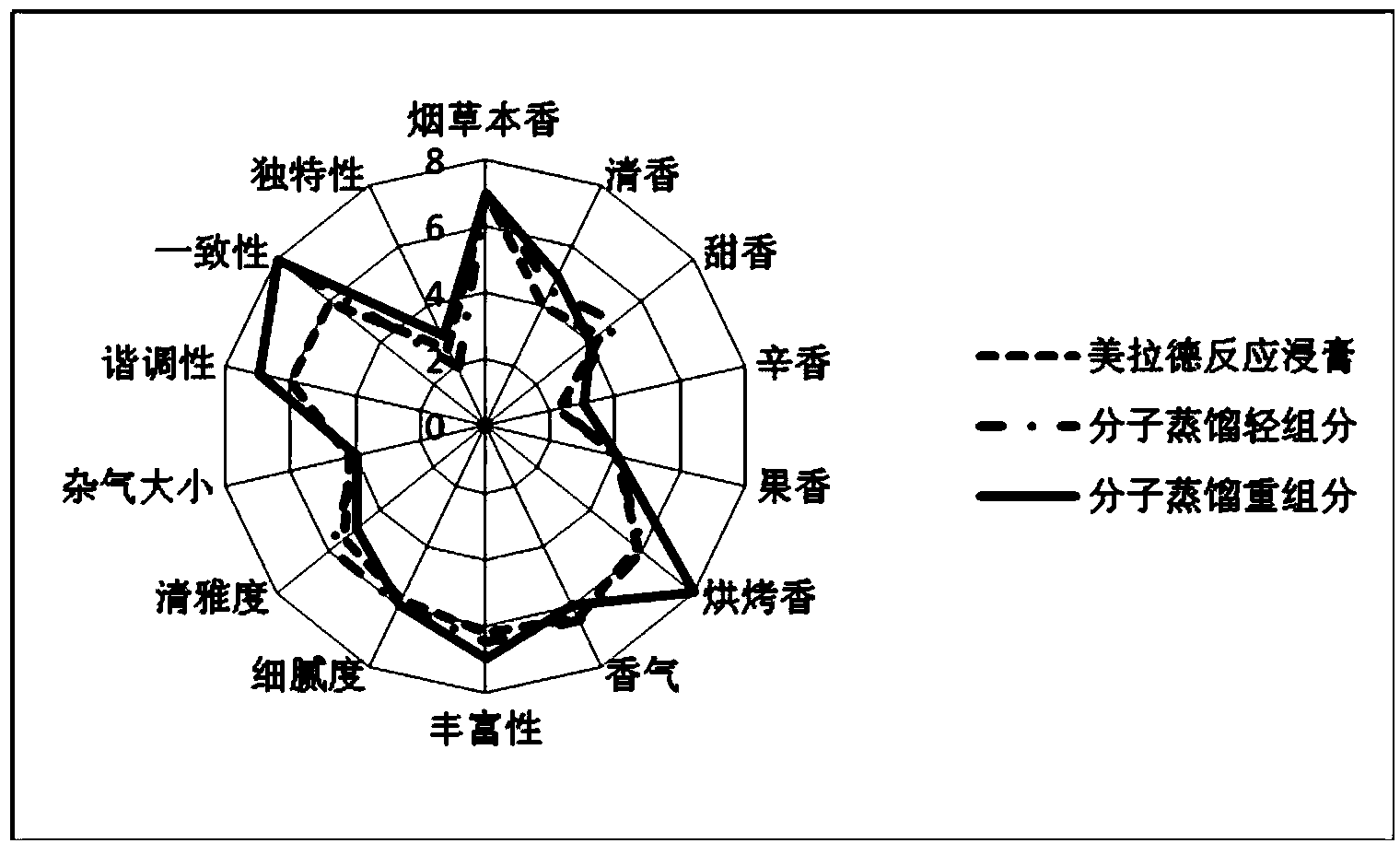

[0027] Crush 3 kg of low-grade tobacco leaves, add water and stir, cook at 100°C for 30 minutes; treat with compound enzyme at 40°C for 4 hours; cook at 100°C for 30 minutes to inactivate the enzyme; add jujube powder to the tobacco at 20: 10: 5: 5:1 , ebony, wild jujube kernel powder, licorice and other auxiliary materials, carry out Maillard reaction at 100-120°C; extract with 95% alcohol, filter, and concentrate the filtrate in vacuum at 50°C to obtain ethanol extract. Then, using ethanol extract as raw material, the optimum conditions for the preparation of tobacco essential oil by molecular distillation were preliminarily determined through experiments: system vacuum 0.1mbar, wiper speed 400r / min, sample flow rate 2mL / min, distillation temperature 80℃. Finally, the essential oil heavy component and light component obtained by molecular distillation are added to the tobacco in a ratio of 5 / 100,000. figure 2 It can be seen that compared with the ethanol extract, the heavy ...

Embodiment 3

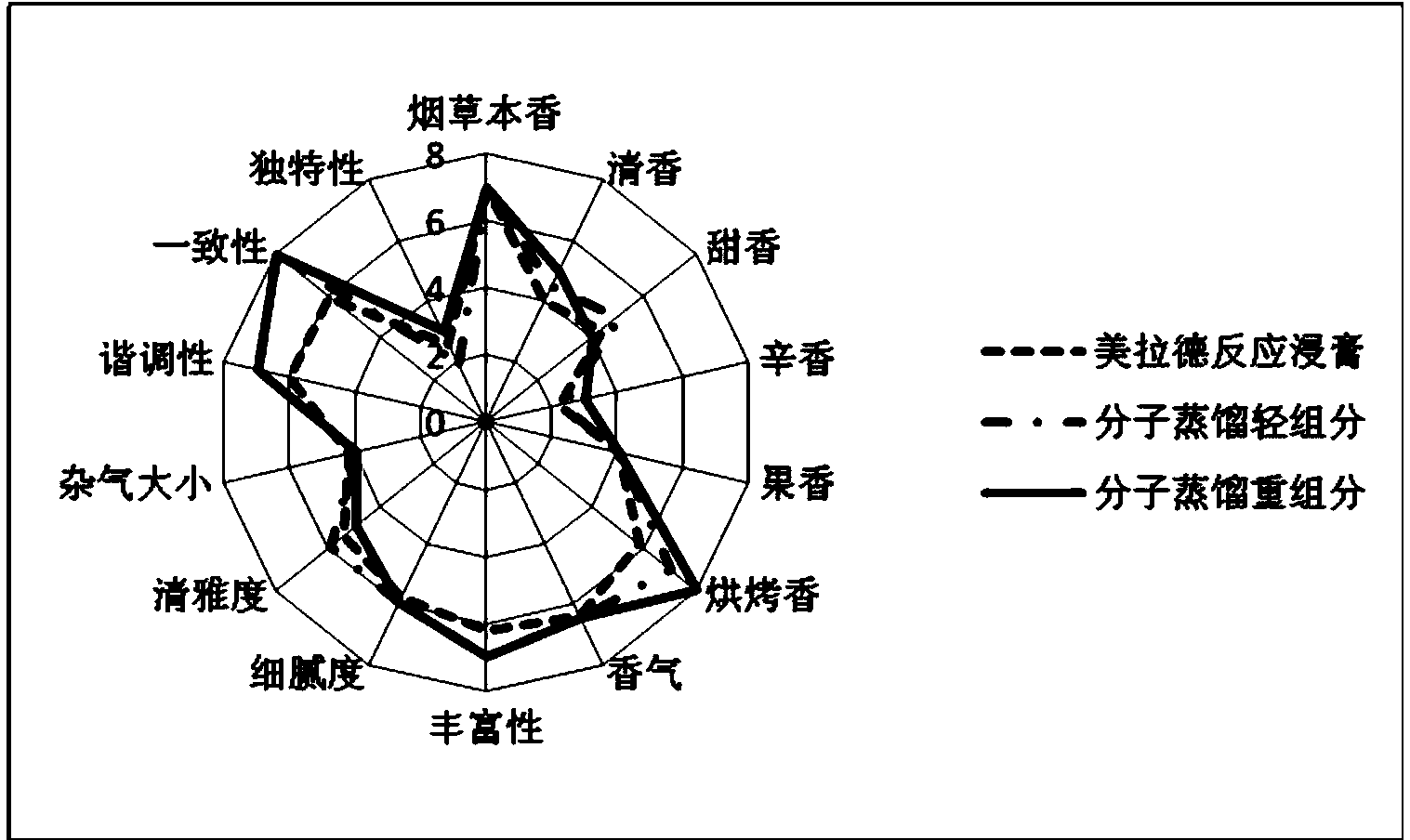

[0029] Crush 3kg of low-grade tobacco leaves, add water and stir, cook at 100°C for 30 minutes; treat with compound enzyme at 40°C for 2 hours; cook at 100°C for 30 minutes to inactivate the enzyme; add jujube powder to the tobacco at a ratio of 20: 5: 5: 5: 1 , ebony, wild jujube kernel powder, licorice and other auxiliary materials, carry out Maillard reaction at 100-120°C; extract with 95% alcohol, filter, and concentrate the filtrate in vacuum at 50°C to obtain ethanol extract. Then, using ethanol extract as raw material, the optimum conditions for the preparation of tobacco essential oil by molecular distillation were preliminarily determined through experiments: system vacuum degree 0.1mbar, wiper speed 250r / min, sample flow rate 1mL / min, distillation temperature 75℃. Finally, the heavy component and light component of the essential oil obtained by molecular distillation are added to the tobacco in a ratio of 1 / 10,000. image 3 It can be seen that the addition of heavy c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com