A horizontal three-way impingement flow mixing reactor

A hybrid reactor and impingement flow technology, applied in the field of reactors, can solve the problems of not fully reflecting the diversity of impact and the high efficiency of micro-mixing, limiting the application of impingement flow technology, and high manufacturing costs of propellers, so as to achieve easy processing and wide application range The effect of wide and low equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

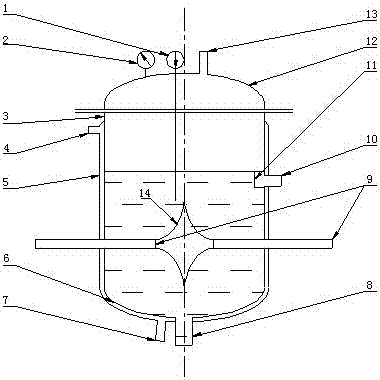

[0022] In the figure: 1-thermometer, 2-pressure gauge, 3-kettle body, 4,7-heat exchange medium inlet and outlet, 5-heating or cooling jacket, 6-bottom of kettle, 8-outlet, 9-feed Mouth, 10-overflow outlet, 11-overflow weir, 12-top cover, 13-gas outlet, 14-impact zone

[0023] The reactor preparation material is stainless steel, and the shape of the kettle body 3 is straight; the upper part is an elliptical top cover 12; the lower part is an elliptical kettle bottom 6, and the outer wall is provided with a heat exchange jacket 5; the head is provided with a gas outlet 13 and a pressure gauge 2 And thermometer 1; Bottom 6 is provided with outlet 8.

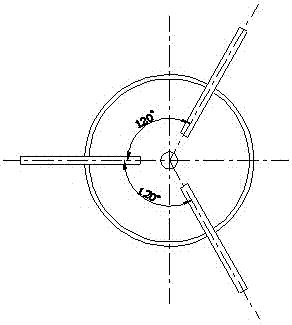

[0024] The pump (not involved in the figure) of the present invention drives the flow of the liquid-phase process medium, passes through the metering control device, and enters the reactor through the feeding pipe 9 arranged at an angle of 120° on the same horizontal plane, and the three fluids are at the center of the kettle body 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com