A vertical foam cement automatic grouting machine

A technology of foamed cement and automatic grouting, which is applied in the direction of ceramic molding machines, supply devices, manufacturing tools, etc., can solve problems such as unfavorable pouring quality efficiency, single grouting function, etc., and achieve the effect of prolonging the setting time and relieving urgency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

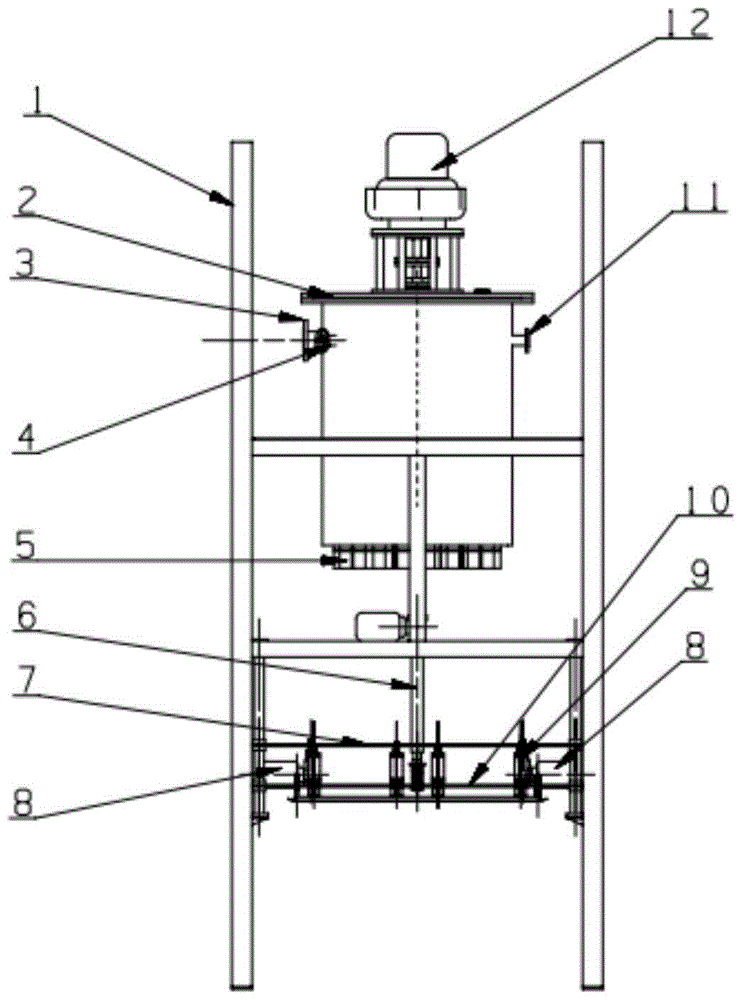

[0028] as attached figure 1 As shown, a vertical foam cement automatic grouting machine is composed of a frame 1, a grouting bucket 2, a grouting valve 9, an electric cylinder for opening and closing valves 8, and an electric lifting cylinder 6. The grouting barrel 2 has a stirring mechanism, a motor 12, a slurry inlet 3, an accelerator adding port 4, an air inlet 11, and a slurry outlet 5; the motor 12 drives the stirring mechanism of the grouting barrel 2 to rotate; Port 3 can be connected with an external mixer through a pipeline, accelerator adding port 4 can be connected with an external accelerator pump through a pipeline, and the air inlet 11 of the grouting bucket 2 can be connected with an external pressurized air pump ; The grout outlet 5 of the grouting barrel 2 is connected with the grouting valve 9 through a transparent hose. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com