Fluoride shaft seal ultrathin rotating cathode end

A technology of rotating cathode and fluoride, applied in ion implantation plating, metal material coating process, coating and other directions, can solve the problems of inability to match the rotating cathode end, the high height of the rotating cathode end, and the increase of equipment cost, etc. Achieve the effect of enhancing equipment vitality, compact structure and reducing equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

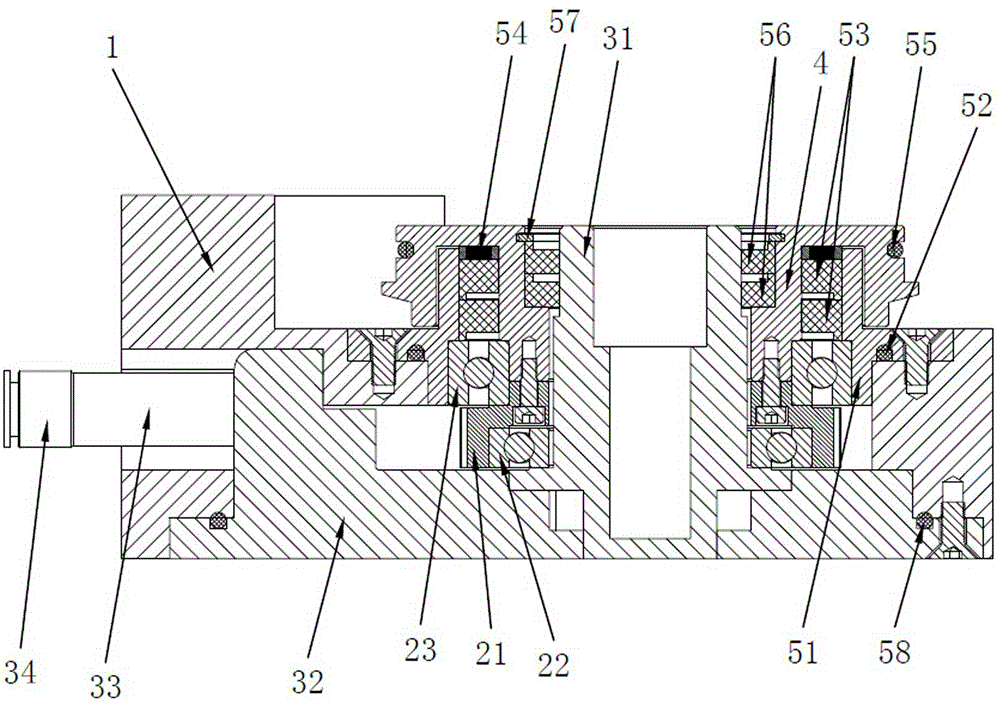

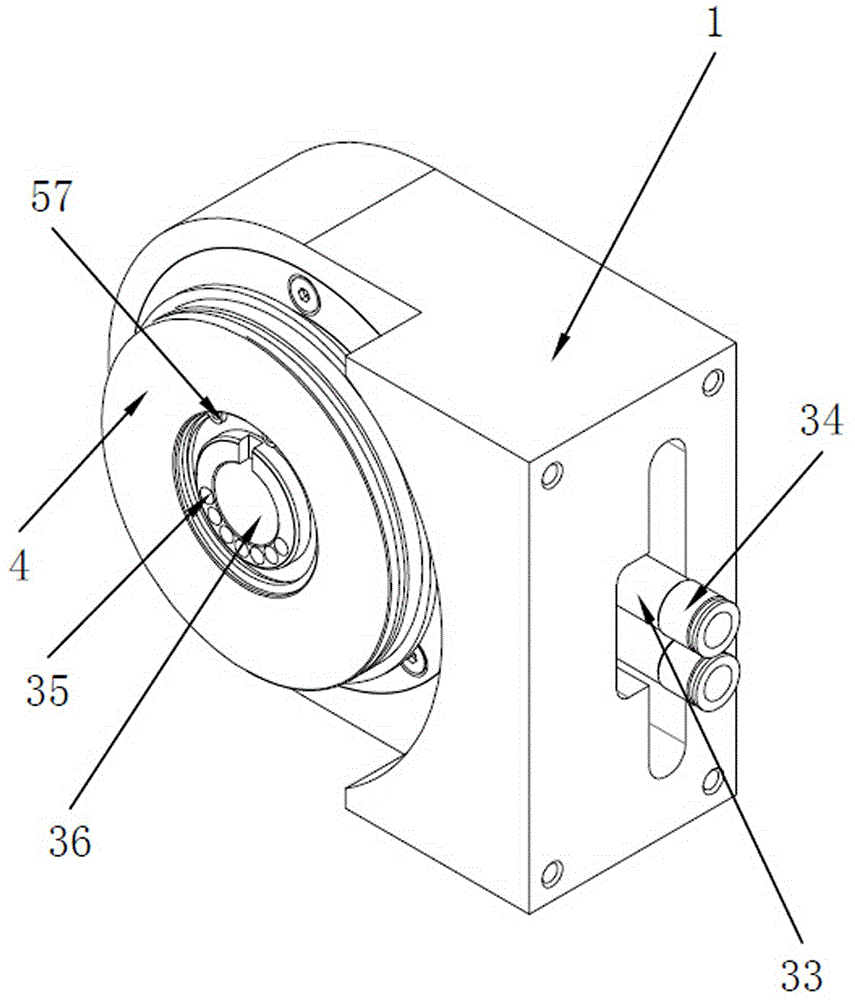

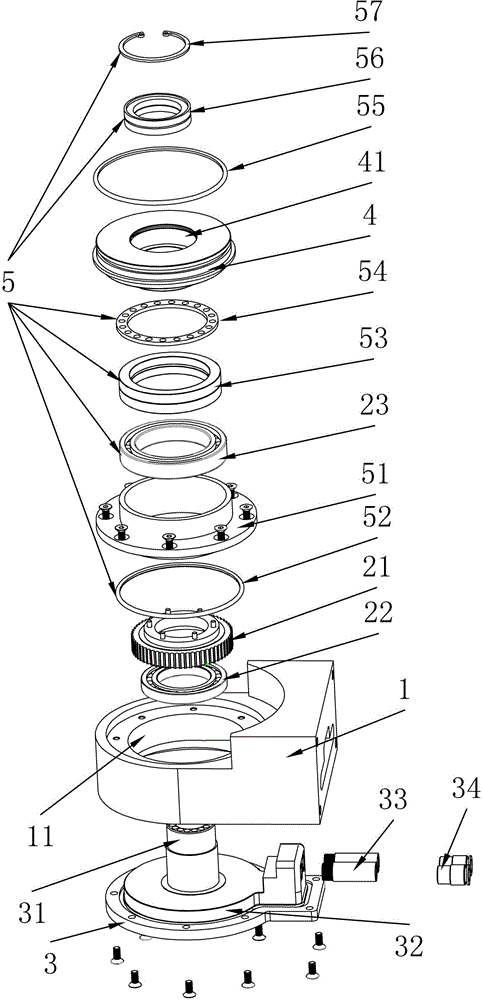

[0026] figure 1 and figure 2 They are schematic diagrams of the structure and appearance of the cathode terminal of the present invention; including a base 1, a first through hole 11 is provided in the middle of the base, and a liquid introduction assembly 3 connected to the base is provided at the bottom of the base for guiding liquid, The top of the base is provided with a lower end cover 4 for installing the target barrel 9, and the middle part of the lower end cover is provided with a second through hole 41, and the head end 31 of the liquid introduction assembly passes through the first through hole and the second through hole. A through hole, a rotating assembly 2 sleeved on the liquid introduction assembly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com