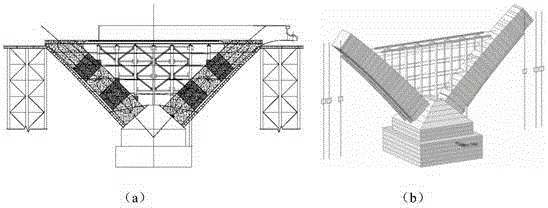

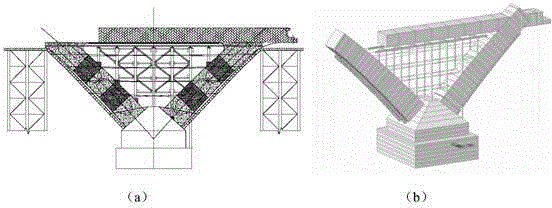

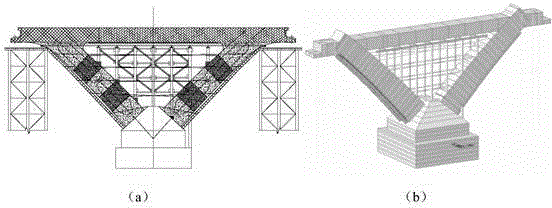

Support-free and opposite pull rod combination construction method for concrete triangular rigid frame in consideration of restraint action of inclined legs

A construction method and technology of triangular rigid frame, which can be used in the erection/assembly of bridges, buildings, bridge construction, etc., and can solve problems such as high cost, instability and collapse, and ill-considered design and construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0056] First, according to the calculation formula k = 2 E b A b ( A a l a 3 sin 2 θ + 3 I a l a cos 2 θ ) 2 E b A b ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com