Wall guard and installation method thereof

An installation method and technology of clapboard, applied in covering/lining, building, building structure, etc., can solve problems such as narrow application range, non-adjustable top line specification, damp base layer of carpentry, etc., so as to improve the safety of use, Avoid weak installation and improve the effect of life cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

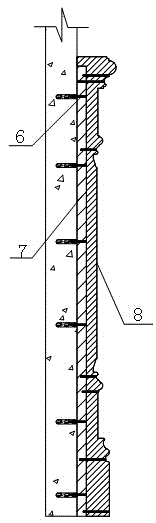

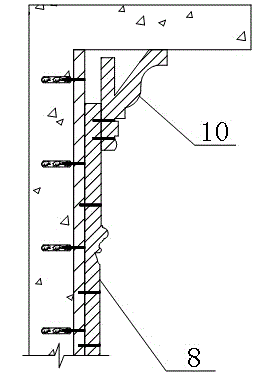

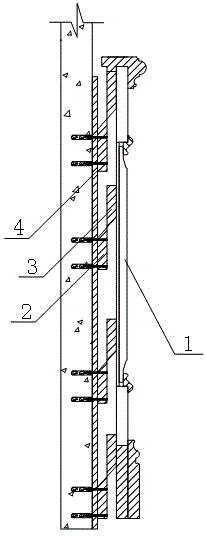

[0068] Such as image 3 , 4 As shown, this embodiment provides a parapet, which includes a parapet 1 and a hook assembly 11 , wherein the parapet is mounted on the wall through the snap assembly. According to the situation of the prior art, it can be seen that the main factors that cause the base layer of the wood board and the wooden clapboard to be damp, moldy and deformed are that the base layer of the wood board is directly in contact with the wall, and the wooden clapboard is directly in contact with the base layer of the wood board. As a result, the moisture contained in the wall penetrates into the base layer of the wood board, and then penetrates into the wooden clapboard through the base layer of the wood board. The direct bonding of a large area accelerates this immersion effect, so it is easy to be damp, moldy, and deformed. In this embodiment, the installation of the wall panel is realized through the above-mentioned hanging buckle assembly, not only the connectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com