Rotary motion oil seal

A technology of rotary motion and oil seal, applied in the direction of engine seals, engine components, mechanical equipment, etc., can solve the problems of dust-proof lip rubber wear, seal failure, dust-proof failure, etc., to reduce the contact area, reduce the friction coefficient, The effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

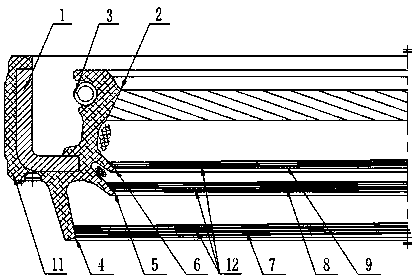

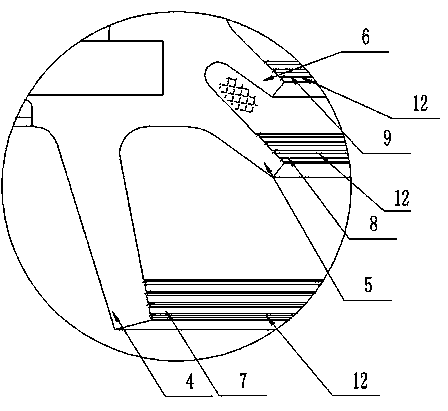

[0031] Example 1, a rotary motion oil seal, refer to figure 1 , figure 2 , Is an elastic sealing body 11 wrapped around the support frame 1. The elastic sealing body 11 is formed with a main sealing lip 2 and a dust lip near the side of the rotating shaft, and a spring 3 is provided on the outside of the main sealing lip 2, and the dust lip is formed The annular sealing surface is provided with a convex or concave stripe 12. In this embodiment, there are three dust-proof lips, which are the first dust-proof lip 4, the second dust-proof lip 5, and the first dust-proof lip. Three dust-proof lips 6, each dust-proof lip forms an annular sealing surface, respectively, the first annular sealing surface 7, the second annular sealing surface 8 and the third annular sealing surface 9, the three dust-proof lips are annular The raised stripes 12 on the sealing surface are annular patterns, which are evenly distributed, and the height of the annular patterns is 0.3 mm.

Embodiment 2

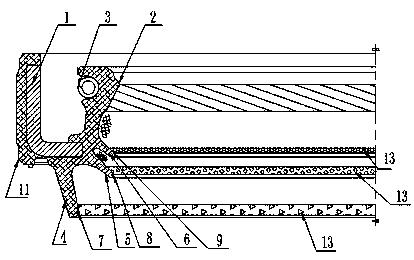

[0032] Example 2, a rotary motion oil seal, refer to image 3 , On the basis of embodiment 1, the annular sealing surface of the dust lip is provided with a plurality of protrusions or pits 13 which form vertical and horizontal grooves on the annular sealing surface of the dust lip. The shape of the protrusions or pits 13 can be hemispherical, tetragonal, truncated cone-shaped or polygonal pyramid shape, and the sealing surface between adjacent protrusions or between adjacent pits 13 can be flat, concave or arc-shaped. Convex arc shape, the dust lip of this embodiment is respectively the first dust lip 4, the second dust lip 5, and the third dust lip 6. Each dust lip forms an annular sealing surface, respectively The first ring sealing surface 7, the second ring sealing surface 8 and the third ring sealing surface 9, the first dust lip ring sealing surface 7 is provided with a plurality of triangular protrusions 13, the second dust lip The annular sealing surface 8 is provided ...

Embodiment 3

[0033] Example 3, a rotary motion oil seal, refer to Figure 4 , Is on the basis of embodiment 2, in this embodiment the first dust lip ring sealing surface 7, the second dust lip ring sealing surface 8, the third dust lip ring sealing surface 9, the first dust lip ring sealing surface The dust lip annular sealing surface 7 is provided with rough point-like protrusions 13, the second dust lip annular sealing surface 8 is provided with a plurality of square grid line protrusions 13, and the third dust lip annular sealing surface 9 A plurality of diamond-shaped grid line protrusions 13 are arranged on the upper surface, and the protrusions 13 are randomly distributed on the annular sealing surface. The height of the protrusions 13 is 0.07 mm, and the others are exactly the same as those in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com